Are you gearing up for an interview for a Garment Sewing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Garment Sewing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

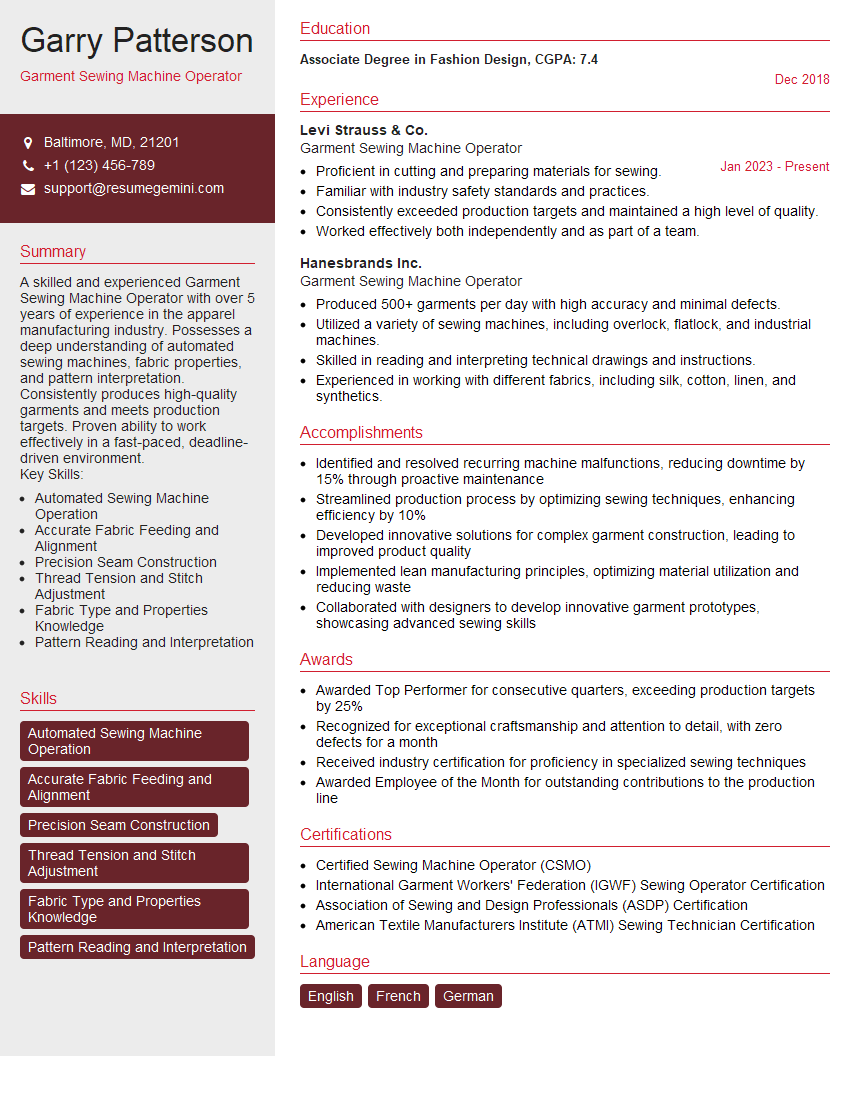

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Garment Sewing Machine Operator

1. How do you ensure the accuracy of the garment measurements while sewing?

- Inspect the fabric carefully before sewing to identify any defects or inconsistencies.

- Use measuring tapes and rulers precisely to mark and measure the fabric.

- Double-check the measurements with a colleague or by using a different measuring tool.

- Use sewing guides or templates to ensure precision when cutting or sewing.

- Regularly calibrate and maintain sewing machines to ensure they are sewing accurately.

2. Describe the different types of needles used in garment sewing machines.

Universal needles

- Suitable for most fabrics

- Sizes range from fine (60/8) to coarse (120/19)

Ballpoint needles

- Round tip prevents snagging on knit fabrics

- Sizes range from 60/8 to 100/16

Stretch needles

- Elastic groove accommodates stretch fabrics without breaking

- Sizes range from 75/11 to 100/16

Leather needles

- Sharp point and reinforced shaft for penetrating leather

- Sizes range from 90/14 to 120/19

3. Explain the process of adjusting the tension on a garment sewing machine.

Adjusting the tension ensures proper stitch formation and prevents puckering or loose threads.

- Identify the tension dials on the machine.

- Lower the tension of the upper thread if stitches are too tight.

- Increase the tension of the lower thread if stitches are too loose.

- Test the tension by sewing a few stitches on scrap fabric.

- Make small adjustments until the tension is balanced and the stitches are even.

4. What are the common causes of skipped stitches on a garment sewing machine?

Skipped stitches can be caused by various factors:

- Incorrect needle size or type

- Dull or damaged needle

- Improper thread tension

- Loose or worn thread

- Fabric too thick or too thin

- Dirty machine parts

5. Describe the different types of seams used in garment construction.

- Plain seam: simplest type, used for joining two fabric edges

- French seam: encloses raw edges, creating a neat and durable finish

- Flat-felled seam: strong and durable, often used in jeans and workwear

- Overlock seam: prevents fraying and creates a stretchy finish

- Blind hem seam: invisible finish, used for hemming garments

6. What are the safety precautions that must be observed when operating a garment sewing machine?

- Keep fingers away from the needle and moving parts.

- Wear safety glasses to protect eyes from flying debris.

- Ensure the machine is properly grounded to prevent electrical shocks.

- Unplug the machine before cleaning or performing maintenance.

- Report any malfunction or damage to the machine immediately.

7. Describe the different types of fabrics used in garment construction and their properties.

- Woven fabrics: strong and durable, made by interlacing yarns

- Knit fabrics: stretchy and flexible, made by looping yarns

- Nonwoven fabrics: bonded without weaving or knitting, often used for interfacing

- Leather: durable and luxurious, made from animal skin

- Suede: soft and velvety, made from the underside of leather

8. How do you maintain a garment sewing machine to ensure optimal performance?

- Regularly clean and oil the machine

- Inspect and replace needles frequently

- Adjust tension settings according to fabric type

- Lubricate moving parts to prevent friction

- Troubleshoot and repair any issues promptly

9. Describe the different types of sewing threads used in garment construction and their applications.

- Cotton thread: strong and durable, suitable for most fabrics

- Polyester thread: strong and colorfast, resistant to abrasion

- Nylon thread: strong and stretchy, used for lingerie and swimwear

- Silk thread: strong and lustrous, used for delicate fabrics

- Metallic thread: decorative and shiny, used for embellishments

10. Explain the importance of following pattern instructions and industry standards when sewing garments.

Following instructions and standards ensures:

- Consistent quality and accuracy

- Avoidance of mistakes and rework

- Compliance with industry best practices

- Ensured fit and functionality of garments

- Efficiency and time-saving

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Garment Sewing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Garment Sewing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Garment Sewing Machine Operators are responsible for operating sewing machines to stitch together pieces of fabric or other materials to create garments, such as shirts, pants, and dresses. Their key responsibilities include:

1. Set up and operate sewing machines

This involves threading the machine, adjusting the tension and stitch settings, and ensuring that the machine is running smoothly.

2. Sew garments according to specifications

Operators must follow instructions and patterns to stitch garments together accurately and efficiently.

3. Inspect garments for quality

They must check for defects, such as uneven stitching, loose threads, or fabric tears.

4. Repair garments

If a garment is damaged, operators may repair it by sewing the tear or replacing a button.

5. Maintain a clean and organized work area

This helps to ensure that the sewing machines are operating properly and that garments are produced in a safe and efficient manner.

Interview Tips

Preparing for an interview for a Garment Sewing Machine Operator position is essential to make a good impression and increase your chances of getting the job. Here are some tips to help you prepare:

1. Research the company and the position

This will help you understand the company’s culture, values, and what they are looking for in a candidate. You can find this information on the company’s website, LinkedIn page, or Glassdoor.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Prepare your answers to these questions in advance so that you can deliver them confidently and clearly.

3. Highlight your skills and experience

Make sure to highlight your skills and experience in your resume and cover letter. Be specific about the types of sewing machines you have operated, the types of garments you have sewn, and any quality control or repair experience you have.

4. Be prepared to demonstrate your skills

You may be asked to demonstrate your sewing skills during the interview. Be prepared to bring a sample of your work or be ready to take a sewing test.

5. Dress professionally and arrive on time

First impressions matter, so make sure to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Garment Sewing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.