Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Garnett Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

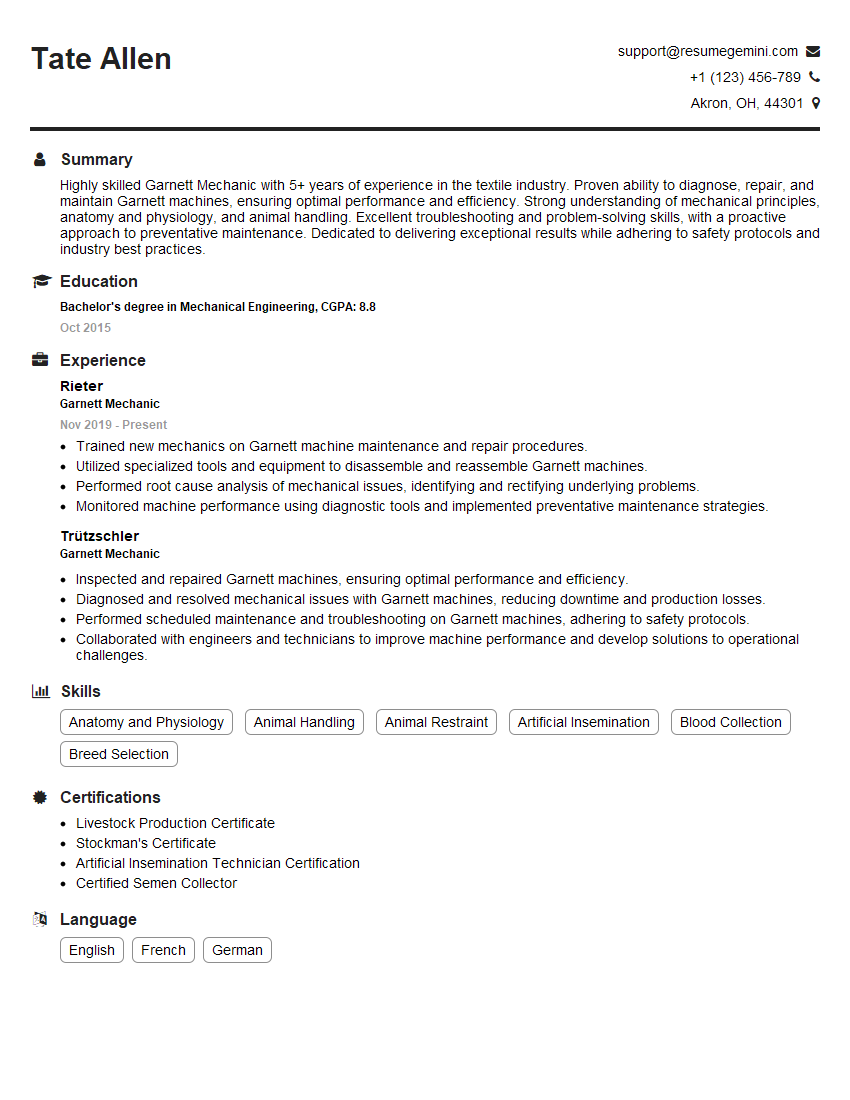

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Garnett Mechanic

1. What are the different types of transmissions and how do they work?

- Manual transmissions are the most common type of transmission in vehicles today. They use a clutch to engage and disengage the engine from the transmission, and a gear shift lever to select the desired gear.

- Automatic transmissions use a torque converter to automatically shift gears. They are more convenient to drive than manual transmissions, but they are also less efficient.

- Continuously variable transmissions (CVTs) use a belt or chain to vary the gear ratio. They are very efficient, but they can be more expensive than other types of transmissions.

2. What are the different types of brake systems and how do they work?

There are two main types of brake systems: hydraulic brake systems and air brake systems. Hydraulic brake systems use brake fluid to transmit force from the master cylinder to the brake calipers or wheel cylinders. Air brake systems use compressed air to transmit force from the brake pedal to the brake calipers or wheel cylinders.

Both hydraulic and air brake systems use a combination of pistons, calipers, and rotors or drums to slow or stop a vehicle. When the brake pedal is depressed, the master cylinder sends brake fluid or compressed air to the brake calipers or wheel cylinders. This force causes the pistons in the calipers or wheel cylinders to extend, which in turn applies pressure to the brake pads or shoes. The brake pads or shoes then rub against the rotors or drums, which slows or stops the vehicle.

3. What are the different types of suspension systems and how do they work?

There are three main types of suspension systems: solid axle suspensions, independent suspensions, and air suspensions.

- Solid axle suspensions use a solid axle to connect the wheels on each side of the vehicle. This type of suspension is simple and durable, but it can be rough and uncomfortable to ride on.

- Independent suspensions use separate suspension components for each wheel. This type of suspension provides a smoother and more comfortable ride, but it is more complex and expensive than solid axle suspensions.

- Air suspensions use air bags to support the vehicle. This type of suspension provides a very smooth and comfortable ride, but it is also the most expensive type of suspension.

4. What are the different types of steering systems and how do they work?

There are two main types of steering systems: rack and pinion steering and recirculating ball steering.

- Rack and pinion steering uses a rack and pinion gear to transmit the steering force to the wheels. This type of steering is simple, efficient, and provides good feedback to the driver.

- Recirculating ball steering uses a recirculating ball and nut to transmit the steering force to the wheels. This type of steering is less efficient than rack and pinion steering, but it is also less expensive.

5. What are the different types of engine cooling systems and how do they work?

There are two main types of engine cooling systems: liquid cooling systems and air cooling systems.

- Liquid cooling systems use a liquid coolant to absorb heat from the engine. The heated coolant is then circulated through a radiator, where it is cooled by air or water.

- Air cooling systems use air to directly cool the engine. Air is circulated over the engine fins, which dissipate heat. Air cooling systems are simpler and lighter than liquid cooling systems, but they are also less efficient.

6. What are the different types of fuel injection systems and how do they work?

There are two main types of fuel injection systems: port fuel injection and direct fuel injection.

- Port fuel injection systems inject fuel into the intake manifold. The fuel is then mixed with air and drawn into the engine cylinders.

- Direct fuel injection systems inject fuel directly into the engine cylinders. This provides more precise control over the fuel injection process, which can improve performance and fuel economy.

7. What are the different types of ignition systems and how do they work?

There are two main types of ignition systems: distributor ignition systems and electronic ignition systems.

- Distributor ignition systems use a distributor to distribute spark to the spark plugs. The distributor is driven by the camshaft, and it opens and closes the points at the appropriate time to create a spark.

- Electronic ignition systems use an electronic control unit (ECU) to control the ignition timing. The ECU uses sensors to determine the engine speed and load, and it adjusts the ignition timing accordingly.

8. What are the different types of exhaust systems and how do they work?

There are two main types of exhaust systems: single exhaust systems and dual exhaust systems.

- Single exhaust systems use a single pipe to carry exhaust gases from the engine to the tailpipe.

- Dual exhaust systems use two pipes to carry exhaust gases from the engine to the tailpipes. Dual exhaust systems can improve performance and sound quality.

9. What are the different types of electrical systems and how do they work?

There are two main types of electrical systems: 12-volt systems and 24-volt systems.

- 12-volt systems are the most common type of electrical system in vehicles today. They use a 12-volt battery to power the vehicle’s electrical components.

- 24-volt systems are used in some heavy-duty vehicles. They use two 12-volt batteries to power the vehicle’s electrical components.

10. What are the different types of diagnostic tools and how do they work?

There are a variety of diagnostic tools that can be used to troubleshoot problems with vehicles. Some of the most common diagnostic tools include:

- Scanners are used to read and clear trouble codes from the vehicle’s computer.

- Multimeters are used to measure voltage, current, and resistance.

- Pressure gauges are used to measure pressure in various parts of the vehicle.

- Temperature gauges are used to measure temperature in various parts of the vehicle.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Garnett Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Garnett Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Garnett Mechanic is responsible for maintaining and repairing garnett machines used in the textile industry. These machines are used to open and clean fibers in cotton, wool, and other natural and synthetic materials.

1. Maintenance and Repair of Garnett Machines

Garnett Mechanics are responsible for performing routine maintenance on garnett machines, including lubrication, adjustments, and repairs. They must also troubleshoot and resolve any issues that arise with the machines.

- Inspect and clean garnett machines to ensure proper operation and prevent breakdowns.

- Replace worn or damaged parts, such as bearings, gears, and belts.

- Adjust and calibrate garnett machines to optimize performance and fiber quality.

- Troubleshoot and repair mechanical and electrical problems with garnett machines.

2. Quality Control

Garnett Mechanics must also ensure that the fibers produced by the garnett machines meet the required quality standards. They may perform tests and inspections to ensure that the fibers are clean, free of impurities, and of the correct size and length.

- Inspect fibers produced by garnett machines to ensure they meet quality standards.

- Perform tests and measurements to determine fiber length, diameter, and purity.

- Adjust garnett machines to optimize fiber quality and minimize defects.

- Collaborate with laboratory technicians to develop and implement quality control procedures.

3. Safety and Compliance

Garnett Mechanics must adhere to all safety regulations and procedures when working with garnett machines. They must also ensure that the machines are operated in accordance with environmental regulations.

- Follow all safety procedures and wear appropriate personal protective equipment.

- Operate garnett machines in accordance with manufacturer’s instructions and industry standards.

- Comply with environmental regulations and ensure proper disposal of hazardous materials.

- Participate in safety training and drills to maintain a safe work environment.

4. Training and Supervision

Garnett Mechanics may also be responsible for training new employees on the operation and maintenance of garnett machines. They may also supervise other mechanics and oversee the maintenance of the garnett machines in the facility.

- Train new employees on the operation and maintenance of garnett machines.

- Supervise other mechanics and oversee the maintenance of garnett machines in the facility.

- Develop and implement training programs to improve the skills and knowledge of mechanics.

- Provide feedback and guidance to mechanics to improve their performance and productivity.

Interview Tips

Preparing for an interview for a Garnett Mechanic position can help you present yourself confidently and increase your chances of success. Here are some tips to help you prepare:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, goals, and the specific responsibilities of the role. You can find information on the company’s website, social media pages, and industry news articles.

- Visit the company’s website to learn about their history, products, and services.

- Check the company’s social media pages for recent news and updates.

- Read industry news articles to stay informed about the latest trends and challenges in the textile industry.

2. Practice Answering Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and concisely. You can also prepare for specific questions related to the job responsibilities of a Garnett Mechanic, such as those listed in the previous section.

- Prepare a brief and engaging introduction that highlights your skills and experience.

- Practice answering questions about your motivation for applying for the position and how your skills align with the job requirements.

- Think about examples from your previous work experience that demonstrate your abilities in maintenance, repair, and troubleshooting.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the job of a Garnett Mechanic. This includes your technical skills, such as your knowledge of garnett machines and your ability to troubleshoot and repair them. It also includes your soft skills, such as your communication and teamwork skills.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Use specific examples to illustrate your skills and experience in maintaining and repairing garnett machines.

- Explain how your soft skills, such as communication and teamwork, contribute to your success in a work environment.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the opportunities for advancement within the company?

- What is the company culture like?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Garnett Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.