Are you gearing up for a career in Gas Booster Engineer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Gas Booster Engineer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

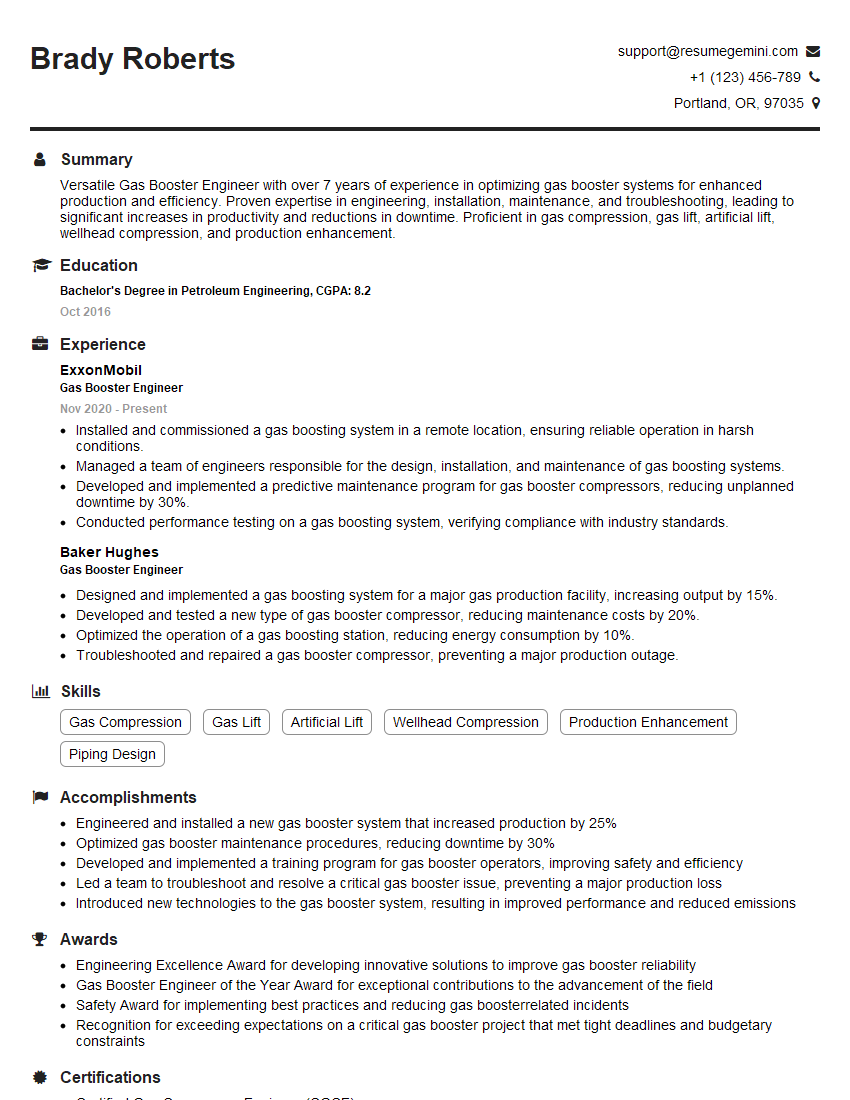

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Booster Engineer

1. What is the function of a gas booster?

A gas booster is a mechanical device designed to increase the pressure of a gas. It is used in various industrial and commercial applications, including:

- Boosting the pressure of natural gas for distribution

- Compressing gases for storage and transportation

- Providing pressure for gas-powered equipment and tools

2. What are the different types of gas boosters?

Reciprocating Gas Boosters

- Piston-driven compressors that use a reciprocating motion to compress gases

Rotary Gas Boosters

- Use rotating impellers or screws to compress gases

Centrifugal Gas Boosters

- Use high-speed impellers to create centrifugal force, compressing gases

3. What are the key factors to consider when selecting a gas booster?

When selecting a gas booster, several key factors need to be considered:

- Required pressure boost

- Flow rate

- Type of gas being compressed

- Operating environment and conditions

- Efficiency and energy consumption

- Maintenance and operating costs

4. What are the common problems associated with gas boosters?

Some common problems that may occur with gas boosters include:

- Leakage

- Overheating

- Valve malfunctions

- Mechanical wear and tear

- Contamination of the gas

5. How do you troubleshoot and maintain a gas booster?

Troubleshooting and maintaining a gas booster involves several steps:

- Identifying the problem or fault

- Checking for leaks or loose connections

- Inspecting valves and other components

- Cleaning and replacing worn or damaged parts

- Performing regular maintenance, including oil changes and filter replacements

6. What safety precautions should be taken when working with gas boosters?

When working with gas boosters, it is crucial to prioritize safety. Some key precautions include:

- Wearing appropriate safety gear, including gloves and safety glasses

- Ensuring proper ventilation to avoid gas buildup

- Following proper operating procedures and guidelines

- Being aware of potential hazards, such as high pressure and flammable gases

- Having emergency response plans in place

7. What are the advancements and trends in gas booster technology?

The gas booster industry is continuously evolving, with advancements in technology. Some notable trends include:

- Development of more efficient and compact designs

- Increased use of automation and control systems

- Focus on reducing noise and emissions

- Exploration of alternative energy sources, such as electric-powered boosters

- Integration of sensors and IoT for remote monitoring and control

8. How do you stay updated on the latest developments in gas booster engineering?

To stay updated on the latest developments in gas booster engineering, I:

- Attend industry conferences and workshops

- Read technical journals and research papers

- Network with other professionals in the field

- Participate in online forums and discussions

- Explore industry websites and resources

9. What are your strengths and weaknesses as a Gas Booster Engineer?

My strengths as a Gas Booster Engineer include:

- Strong understanding of gas booster principles and applications

- Proficient in troubleshooting and maintenance

- Excellent analytical and problem-solving skills

- Experience in designing and optimizing gas booster systems

- Ability to work independently and as part of a team

As for my weaknesses, I am always looking for opportunities to:

- Expand my knowledge in emerging technologies

- Gain more experience in project management

- Improve my communication and presentation skills

10. Why are you interested in this Gas Booster Engineer position?

I am eager to join your organization as a Gas Booster Engineer because:

- I am passionate about gas booster technology and its applications

- I am confident that my skills and experience align with the requirements of this role

- I am excited about the opportunity to contribute to the success of your team

- I am eager to learn from experienced professionals and contribute to the advancement of gas booster engineering

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Booster Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Booster Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gas Booster Engineers are responsible for the design, installation, maintenance, and repair of gas booster systems. They work in a variety of industries, including oil and gas, chemical processing, and manufacturing.

1. Design and Installation

Gas Booster Engineers design and install gas booster systems that meet the specific needs of their clients. They consider factors such as the flow rate, pressure, and temperature of the gas, as well as the type of environment in which the system will be installed.

- Determine the required flow rate, pressure, and temperature of the gas booster system.

- Select the appropriate type of gas booster system for the application.

- Design the layout of the gas booster system.

- Install the gas booster system according to the design specifications.

2. Maintenance and Repair

Gas Booster Engineers maintain and repair gas booster systems to ensure that they are operating safely and efficiently. They perform regular inspections, troubleshoot problems, and replace worn or damaged parts.

- Inspect gas booster systems for signs of wear or damage.

- Troubleshoot problems with gas booster systems.

- Repair or replace worn or damaged parts on gas booster systems.

- Perform preventive maintenance on gas booster systems to prevent problems from occurring.

3. Safety

Gas Booster Engineers are responsible for ensuring that gas booster systems are operated safely. They develop and implement safety procedures, and they train operators on how to use the systems safely.

- Develop and implement safety procedures for gas booster systems.

- Train operators on how to use gas booster systems safely.

- Monitor gas booster systems for potential hazards.

- Respond to emergencies involving gas booster systems.

4. Troubleshooting

Gas Booster Engineers are responsible for troubleshooting problems with gas booster systems. They use their knowledge of the systems to identify the source of the problem and develop a solution.

- Identify the source of problems with gas booster systems.

- Develop and implement solutions to problems with gas booster systems.

- Test solutions to problems with gas booster systems to ensure that they are effective.

- Document problems with gas booster systems and their solutions.

Interview Tips

Here are some tips for acing an interview for a Gas Booster Engineer position:

1. Research the Company

Before the interview, take some time to research the company you are applying to. This will help you to understand their business, their culture, and their values. You can find information about the company on their website, social media pages, and Glassdoor.

2. Prepare Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be Enthusiastic and Positive

Employers are looking for candidates who are enthusiastic and positive about their work. Be sure to convey your passion for gas booster engineering and your desire to work for the company.

4. Demonstrate Your Skills and Experience

In the interview, be sure to highlight your skills and experience that are relevant to the position. Use specific examples to illustrate your abilities.

5. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the opportunity and that you are taking the interview seriously.

Next Step:

Now that you’re armed with the knowledge of Gas Booster Engineer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Gas Booster Engineer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini