Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Gas Compressor Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Gas Compressor Operator so you can tailor your answers to impress potential employers.

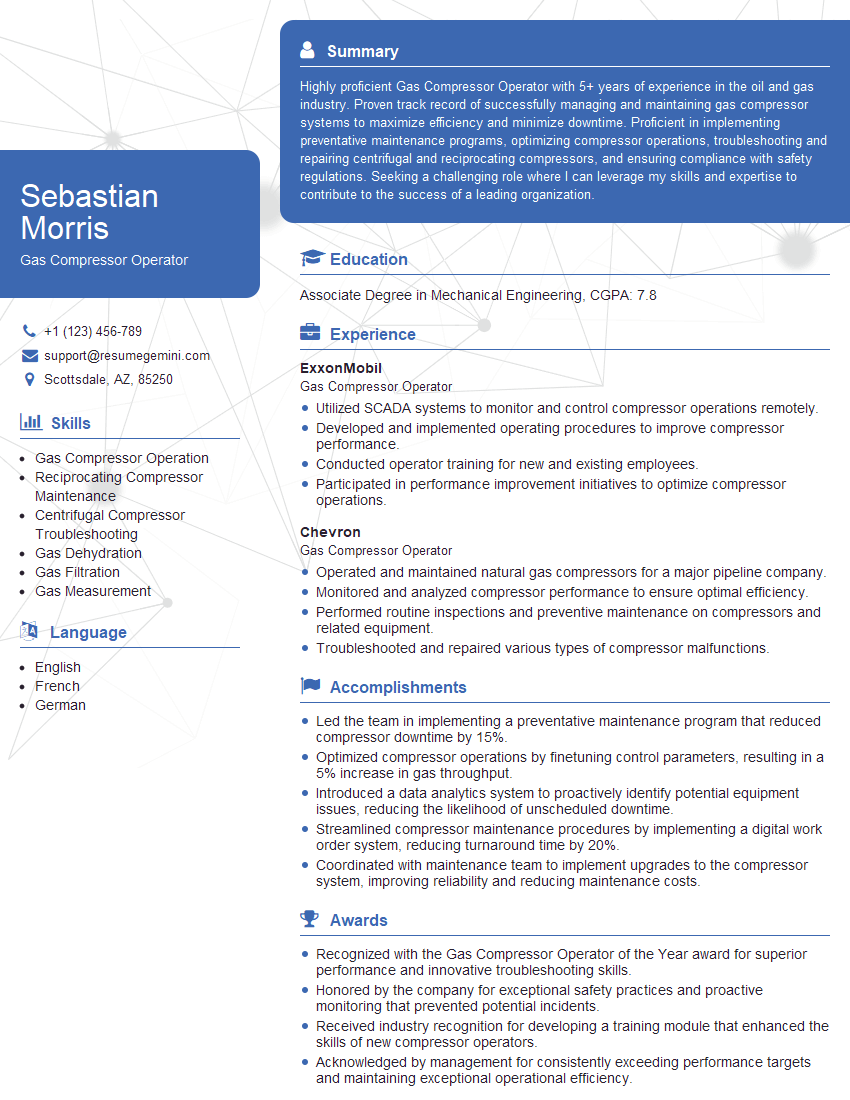

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Compressor Operator

1. Describe the steps you would take to troubleshoot a gas compressor that is not starting.

Sure! I’d be happy to walk you through the steps I would take to troubleshoot a gas compressor that is not starting:

- Check the power supply. Make sure that the compressor is plugged in and that the power switch is turned on. Also, check the circuit breaker or fuse to ensure that it has not tripped.

- Check the oil level. Low oil levels can prevent the compressor from starting. Check the oil level and add oil if necessary.

- Check the air filter. A dirty air filter can restrict airflow and prevent the compressor from starting. Remove the air filter and clean or replace it if necessary.

- Check the pressure switch. A faulty pressure switch can prevent the compressor from starting. Check the pressure switch and replace it if necessary.

- Check the motor. A faulty motor can prevent the compressor from starting. Check the motor for any signs of damage and replace it if necessary.

2. What are the different types of gas compressors?

Reciprocating Compressors

- Positive displacement compressors that use a piston to compress gas.

- Can be single-acting (compression occurs on one side of the piston) or double-acting (compression occurs on both sides of the piston).

- Suitable for high-pressure applications.

Rotary Screw Compressors

- Positive displacement compressors that use two intermeshing screws to compress gas.

- Oil-injected or oil-free.

- Provide a continuous flow of compressed gas.

Centrifugal Compressors

- Dynamic compressors that use a rotating impeller to compress gas.

- Suitable for high-volume, low-pressure applications.

- Can be single-stage or multi-stage.

Axial Compressors

- Dynamic compressors that use a series of rotating and stationary blades to compress gas.

- Suitable for high-pressure, high-volume applications.

- Used in jet engines and gas turbines.

3. What are the safety precautions that must be taken when operating a gas compressor?

- Wear appropriate PPE. This includes safety glasses, hearing protection, and gloves.

- Be aware of the location of the emergency stop button.

- Do not operate the compressor in a confined space.

- Keep the compressor well-ventilated.

- Do not smoke or use open flames near the compressor.

- Be aware of the pressure rating of the compressor and the hoses and fittings being used.

- Do not exceed the maximum pressure rating of the compressor.

- Inspect the compressor regularly for any signs of damage.

4. What are the different maintenance tasks that need to be performed on a gas compressor?

- Regularly check and change the oil.

- Clean or replace the air filter.

- Inspect the belts and hoses for wear and tear.

- Check the pressure switch and other safety devices.

- Visually inspect the compressor for any signs of damage.

- Perform a leak test on the compressor and its components.

5. What are the signs and symptoms of a failing gas compressor?

- The compressor is not starting.

- The compressor is running but not producing any compressed air.

- The compressor is making excessive noise or vibration.

- The compressor is overheating.

- There is a leak in the compressor or its components.

6. What are the different types of gas compressor controls?

- Manual controls – The operator manually starts and stops the compressor and adjusts the pressure and flow rate.

- Automatic controls – The compressor is controlled by a programmable logic controller (PLC) or other electronic device that monitors the pressure and flow rate and automatically adjusts the compressor’s operation.

- Remote controls – The compressor can be started, stopped, and adjusted remotely using a computer or other device.

7. What are the different applications of gas compressors?

- Industrial applications: Gas compressors are used in a wide variety of industrial applications, such as manufacturing, mining, and construction.

- Oil and gas industry: Gas compressors are used to compress natural gas for transportation and storage.

- Power generation: Gas compressors are used to compress air for use in gas turbines and other power generation equipment.

- Medical applications: Gas compressors are used to compress oxygen and other medical gases for use in hospitals and other medical facilities.

- Transportation: Gas compressors are used to compress air for use in braking systems and other pneumatic applications in vehicles.

8. What are the advantages of using a gas compressor?

- Increased pressure: Gas compressors can increase the pressure of a gas, making it suitable for various applications.

- Reduced volume: Compressing a gas reduces its volume, making it easier to store and transport.

- Increased efficiency: Gas compressors can increase the efficiency of gas-powered engines and other devices by providing a higher pressure gas supply.

- Improved safety: Compressing a gas can make it safer to handle and store.

- Versatility: Gas compressors can be used for a wide variety of applications, from industrial manufacturing to medical use.

9. What are the disadvantages of using a gas compressor?

- Energy consumption: Gas compressors require energy to operate, which can increase operating costs.

- Noise: Gas compressors can be noisy, especially when operating at high pressures.

- Heat generation: Gas compressors can generate heat, which can be a concern in some applications.

- Maintenance: Gas compressors require regular maintenance to ensure optimal performance and safety.

- Risk of leaks: Gas compressors can develop leaks, which can pose safety and environmental hazards.

10. What are the latest trends in gas compressor technology?

- Increased efficiency: Manufacturers are constantly developing new technologies to improve the efficiency of gas compressors, reducing energy consumption and operating costs.

- Reduced noise: New designs and materials are being used to reduce the noise levels of gas compressors, making them more suitable for use in sensitive environments.

- Improved reliability: Gas compressor manufacturers are focusing on improving the reliability of their products, reducing downtime and maintenance costs.

- Increased automation: Gas compressors are becoming increasingly automated, allowing for remote monitoring and control, reducing the need for manual intervention.

- Environmentally friendly: Manufacturers are developing gas compressors that are more environmentally friendly, using low-emission technologies and sustainable materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Compressor Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Compressor Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gas Compressor Operators play a vital role in the oil and gas industry, ensuring efficient and safe operation of gas compressors and related equipment at production and processing facilities. Their key responsibilities encompass:

1. Compressor Operations

Monitoring and controlling gas compressors

- Starting, stopping, and regulating compressor speed to maintain desired gas flow rates and pressures

- Performing routine inspections and maintenance

2. Safety and Compliance

Adhering to safety protocols and operating procedures

- Identifying and mitigating potential hazards

- Reporting incidents and accidents

3. Equipment Maintenance

Inspecting and servicing compressors and auxiliary equipment

- Cleaning, lubricating, and replacing components

- Troubleshooting and repairing minor issues

4. Process Optimization

Monitoring and analyzing compressor performance

- Identifying areas for improvement

- Collaborating with engineers and technicians

Interview Tips

To ace an interview for a Gas Compressor Operator position, it’s important to prepare thoroughly and demonstrate your skills and knowledge. Here are some essential tips:

1. Technical Expertise

Familiarize yourself with the principles of gas compression, types of compressors, and their applications.

- Highlight your understanding of compressor design, operation, and maintenance.

- Provide examples of your experience in troubleshooting and resolving compressor issues.

2. Safety and Regulations

Emphasize your understanding of safety protocols and industry regulations related to gas compressor operations.

- Discuss your knowledge of emergency procedures and hazard identification.

- Explain how you adhere to environmental regulations and maintain a safe work environment.

3. Communication and Teamwork

Gas Compressor Operators often work in teams and collaborate with engineers and technicians. Highlight your communication and teamwork skills.

- Describe how you effectively communicate with colleagues and resolve conflicts.

- Emphasize your ability to work independently and as part of a team.

4. Continuous Improvement

Gas Compressor Operators should demonstrate a commitment to continuous improvement and learning.

- Discuss your experience in seeking opportunities for professional development.

- Share examples of how you have implemented new technologies or introduced process improvements.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gas Compressor Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!