Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gas Main Fitter Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

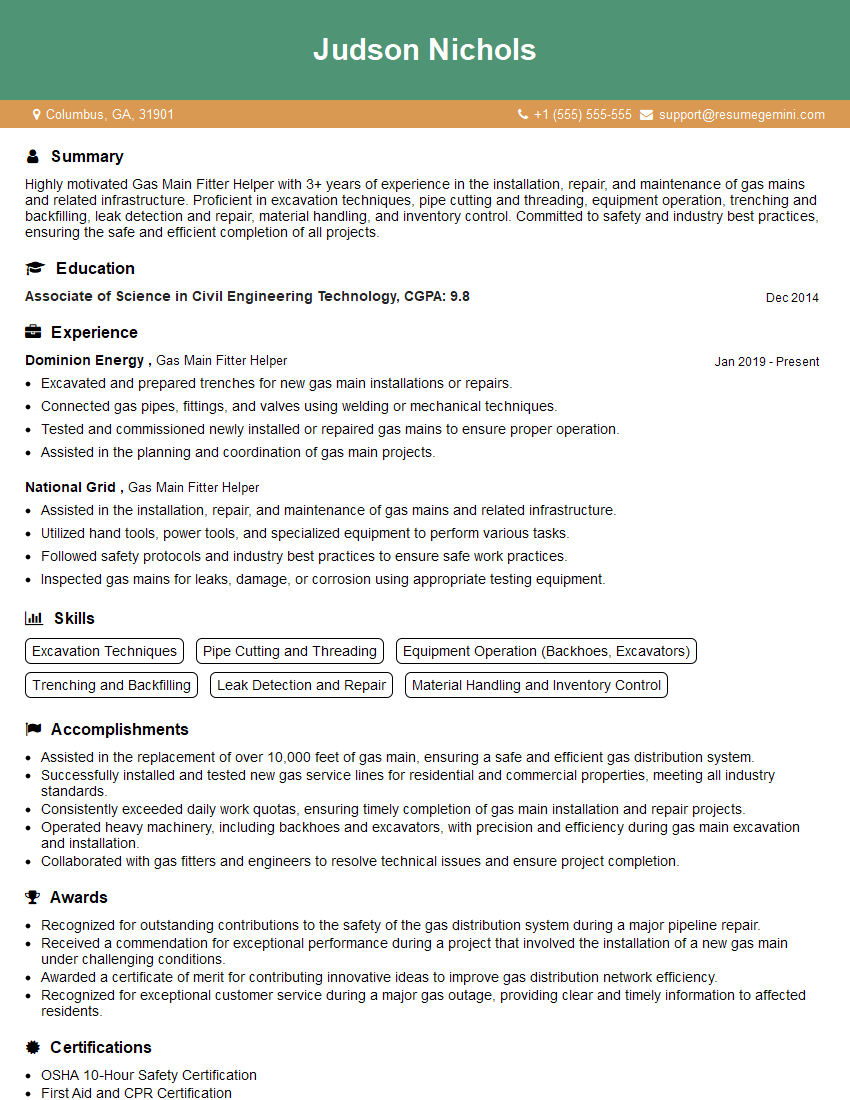

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Main Fitter Helper

1. How do you ensure the safety of the work area before starting any gas main fitting work?

I follow a comprehensive safety protocol to ensure the work area is safe before commencing any gas main fitting work. My safety measures include:

- Identifying and marking all underground utilities to avoid any potential hazards.

- Setting up proper barricades and warning signs to prevent unauthorized access to the work area.

- Ventilating the work area adequately to prevent the accumulation of harmful gases.

- Testing the atmosphere for explosive or flammable vapors before starting any operations.

- Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a hard hat.

2. What are the key steps involved in connecting a gas main to a building?

Excavation and Preparation

- Carefully excavate the ground to expose the gas main and the building’s gas line.

- Ensure the excavated area is stable and free from any obstructions.

Connection

- Clean and prepare the ends of the gas main and the building’s gas line.

- Securely connect the two using an appropriate fitting and sealant.

- Tighten all connections to the manufacturer’s specifications.

Testing and Backfilling

- Thoroughly test the connection for leaks using an approved method.

- Backfill the excavated area with suitable material, compacting it to ensure proper support.

- Restore the work area to its original condition.

3. How do you locate and mark underground gas lines?

Locating and marking underground gas lines is crucial for safe excavation work. I employ the following steps to ensure accurate identification:

- Contact the local utility company to obtain gas line maps and mark-outs.

- Use a gas line locator to pinpoint the exact location of the lines.

- Mark the lines clearly using paint, flags, or other appropriate markers.

- Respect the marked areas and maintain a safe distance during excavation.

4. What types of materials are commonly used in gas main fitting, and how do you handle them safely?

Various materials are used in gas main fitting, each with its specific properties and safety considerations:

- Polyethylene (PE): Flexible and resistant to corrosion, requiring proper handling to avoid kinks or damage.

- Steel: Strong and durable, but susceptible to rust, necessitating proper coating and protection.

- Copper: Malleable and corrosion-resistant, requiring care during bending and fitting to prevent cracks.

- PVC: Lightweight and easy to handle, but can become brittle in cold temperatures, requiring proper storage and handling.

5. What are the potential hazards associated with gas main fitting, and how do you mitigate them?

Gas main fitting involves potential hazards that must be addressed for safety:

- Gas leaks: Can cause explosions or fires, requiring immediate identification and repair.

- Underground hazards: Buried utilities, rocks, or other obstacles can pose risks, necessitating careful excavation.

- Flammable materials: Gas and other flammable materials must be handled carefully to prevent ignition.

- Confined spaces: Trenches or underground vaults can present limited access and ventilation, requiring proper safety measures.

- Physical hazards: Heavy lifting, awkward postures, and extreme weather conditions can strain the body, necessitating proper ergonomics and precautions.

6. How do you test the integrity of a gas line after installation or repair?

Testing the integrity of a gas line is crucial to ensure its safety and reliability:

- Pressure testing: Applying pressurized air or nitrogen to the line and monitoring for any leaks or pressure drops.

- Bubble testing: Applying a soapy solution to the joints and connections, observing for bubbles that indicate leaks.

- Electronic leak detectors: Using specialized equipment to detect even small gas leaks.

- Infrared imaging: Utilizing infrared cameras to identify temperature variations that may indicate leaks.

7. What maintenance procedures are essential for gas mains to ensure their long-term functionality?

Regular maintenance is key to maintaining the safety and efficiency of gas mains:

- Visual inspections: Periodically inspecting the lines for corrosion, leaks, or any visible damage.

- Pressure monitoring: Monitoring gas pressure levels to identify potential issues or leaks.

- Leak detection surveys: Using specialized equipment to detect gas leaks along the entire length of the main.

- Cathodic protection: Employing cathodic protection systems to prevent corrosion in underground steel pipelines.

8. How do you handle emergencies such as gas leaks or burst pipes during gas main fitting operations?

In an emergency, swift and decisive action is crucial:

- Immediate evacuation: Evacuate the affected area and ensure the safety of all personnel.

- Shut-off gas supply: Locate and shut off the main gas supply to stop the flow.

- Call emergency services: Contact the fire department or gas utility immediately for assistance.

- Ventilate the area: Open doors and windows to disperse the gas and prevent accumulation.

- Stay informed: Monitor updates from emergency services and follow their instructions.

9. Describe your experience in using specialized tools and equipment in gas main fitting.

I am proficient in operating a range of specialized tools and equipment essential for gas main fitting:

- Trenchers: Using trenching machines to efficiently excavate trenches for gas line installation.

- Pipe benders: Bending gas pipes to the required angles and shapes without compromising their integrity.

- Welding and cutting equipment: Safely welding and cutting gas pipes to create secure joints and connections.

- Leak detection equipment: Utilizing electronic leak detectors and other methods to identify and locate gas leaks.

- Pressure testing equipment: Operating pressure gauges and other equipment to test the integrity and pressure levels of gas lines.

10. How do you stay updated on the latest industry regulations and safety standards for gas main fitting?

Staying current with industry regulations and safety standards is paramount for safe and compliant gas main fitting practices:

- Regular training: Attending industry training programs and workshops to enhance knowledge and skills.

- Industry publications: Reading trade magazines and journals to stay informed about new technologies, regulations, and best practices.

- Online resources: Utilizing online platforms and databases to access technical information, safety guidelines, and industry updates.

- Collaboration with colleagues: Engaging in discussions and sharing knowledge with other gas main fitters and industry professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Main Fitter Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Main Fitter Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Assists a gas main fitter in the installation, maintenance, and repair of gas mains and associated equipment.

1. Assist with Installation

Performs tasks such as hauling materials, digging trenches, and helping to assemble and install gas main components.

- Unloads and stacks materials such as pipes, fittings, and valves.

- Assists in excavating trenches for pipe installation, using shovels and other tools.

- Helps to assemble and install gas main components, such as pipes, fittings, and meters.

2. Assist with Maintenance

Conducts routine inspections, monitors system operations, and performs minor repairs to ensure the safe and efficient operation of the gas main system.

- Inspects gas mains and associated equipment for leaks, corrosion, or damage.

- Monitors system operations, such as pressure and flow rates, to ensure that the system is functioning properly.

- Performs minor repairs, such as replacing gaskets or tightening bolts, to maintain the integrity of the system.

3. Assist with Repairs

Assists with major repairs and replacements of gas main components, such as pipes, fittings, and valves.

- Excavate trenches to access damaged components.

- Remove and replace damaged components, such as pipes, fittings, and valves.

- Backfill trenches and restore work areas to their original condition.

4. Safety and Compliance

Adheres to all safety regulations and industry standards to ensure the safety of themselves, co-workers, and the public.

- Wears appropriate safety gear, such as gloves, hard hats, and safety glasses.

- Follows established safety procedures, such as lockout/tagout and trenching safety.

- Reports any unsafe conditions or practices to their supervisor.

Interview Tips

To ace your interview for a Gas Main Fitter Helper position, it is important to prepare thoroughly and demonstrate your knowledge and skills.

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and the specific requirements of the gas main fitter helper position.

- Visit the company’s website and social media pages.

- Review the job description carefully and identify the key responsibilities and qualifications.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in your resume and during the interview.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Use action verbs to describe your responsibilities and accomplishments.

- Provide specific examples of how you have used your skills to contribute to the success of previous projects.

3. Prepare for Common Interview Questions

Practice answering common interview questions, such as:

- Tell me about your experience in the gas industry.

- What are your strengths and weaknesses as a Gas Main Fitter Helper?

- Why are you interested in this position?

- What is your availability for work?

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company.

- Prepare a few questions in advance, such as:

- What is the company’s safety record?

- What are the opportunities for advancement?

- What is the company’s commitment to training and development?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gas Main Fitter Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.