Are you gearing up for a career in Gas Main Fitter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Gas Main Fitter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

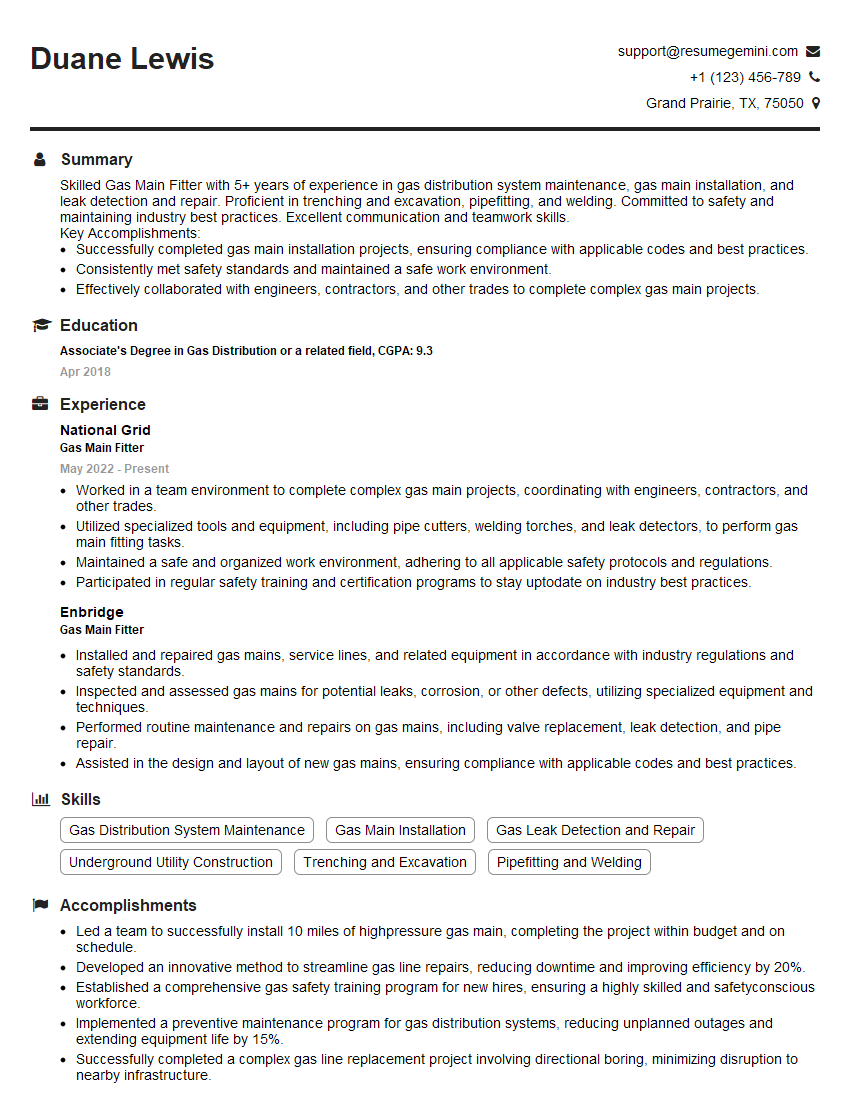

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Main Fitter

1. What are the different types of gas main materials and their advantages and disadvantages?

The following are the different types of gas main materials, along with their advantages and disadvantages:

- Cast iron: Cast iron is a strong and durable material that has been used for gas mains for over a century. However, it is also heavy and brittle, and it can be difficult to work with.

- Steel: Steel is a strong and lightweight material that is easy to work with. However, it is also susceptible to corrosion, and it can be more expensive than other materials.

- Polyethylene: Polyethylene is a flexible and durable material that is resistant to corrosion. However, it is not as strong as steel or cast iron, and it can be more difficult to join.

- PVC: PVC is a lightweight and inexpensive material that is easy to work with. However, it is not as strong as steel or cast iron, and it can be more susceptible to damage from heat and sunlight.

2. What are the steps involved in installing a gas main?

Excavation

- The first step is to excavate a trench for the gas main. The trench should be deep enough to allow for the gas main to be buried at a depth of at least 24 inches.

- The trench should also be wide enough to allow for the gas main to be installed with a minimum of 6 inches of clearance on all sides.

Pipe installation

- Once the trench has been excavated, the gas main can be installed. The gas main should be installed in accordance with the manufacturer’s instructions.

- The gas main should be joined together using the appropriate fittings and sealants.

Backfilling

- Once the gas main has been installed, the trench can be backfilled. The backfill material should be compacted to prevent the gas main from settling.

- The backfill material should also be graded to allow for water to drain away from the gas main.

3. What are the different types of gas main joints and their advantages and disadvantages?

- Mechanical joints: Mechanical joints are made using a variety of fittings, such as flanges, couplings, and unions. Mechanical joints are easy to install and disassemble, and they can be used with a variety of pipe materials.

- Welded joints: Welded joints are made by fusing the pipe ends together using a welding torch. Welded joints are strong and durable, but they can be difficult to install and disassemble.

- Threaded joints: Threaded joints are made by screwing the pipe ends together. Threaded joints are easy to install and disassemble, but they are not as strong as welded joints.

4. What are the different types of gas main valves and their functions?

- Gate valves: Gate valves are used to isolate sections of gas main. Gate valves are opened and closed by turning a wheel or lever.

- Globe valves: Globe valves are used to regulate the flow of gas. Globe valves are opened and closed by turning a wheel or lever.

- Check valves: Check valves are used to prevent the flow of gas in one direction. Check valves are opened and closed by the pressure of the gas.

- Relief valves: Relief valves are used to release excess pressure from a gas main. Relief valves are opened and closed by the pressure of the gas.

5. What are the safety precautions that must be taken when working on a gas main?

- Wear appropriate personal protective equipment (PPE): This includes a hard hat, safety glasses, gloves, and a long-sleeved shirt.

- Ventilate the work area: This will help to prevent the accumulation of gas fumes.

- Use a gas detector: This will help to detect the presence of gas leaks.

- Follow all safety procedures: This includes following the manufacturer’s instructions for the equipment being used.

6. What are the different types of gas main leaks and how can they be detected?

- Small leaks: Small leaks can be detected by using a gas detector. Small leaks can be repaired by using a variety of methods, such as patching or welding.

- Large leaks: Large leaks can be detected by the sound of escaping gas or by the smell of gas. Large leaks can be dangerous and should be repaired immediately.

- Leaks in underground gas mains: Leaks in underground gas mains can be detected by using a variety of methods, such as ground-penetrating radar or by using a gas detector.

7. What are the different types of gas main repairs and how are they performed?

- Patching: Patching is a temporary repair that is used to stop a small leak. Patching is done by applying a patch over the leak.

- Welding: Welding is a permanent repair that is used to seal a leak. Welding is done by fusing the pipe ends together using a welding torch.

- Replacement: Replacement is the most permanent repair that is used to fix a leak. Replacement is done by replacing the damaged section of pipe with a new section of pipe.

8. What are the different types of gas main inspections and how are they performed?

- Visual inspections: Visual inspections are performed by visually inspecting the gas main for any signs of damage or leaks.

- Pressure tests: Pressure tests are performed by pressurizing the gas main and then monitoring the pressure for any drops. Pressure drops can indicate the presence of a leak.

- Leak detection surveys: Leak detection surveys are performed using a variety of methods, such as ground-penetrating radar or by using a gas detector.

9. What are the different types of gas main maintenance and how are they performed?

- Preventive maintenance: Preventive maintenance is performed on a regular basis to help prevent leaks and other problems. Preventive maintenance includes tasks such as cleaning the gas main, inspecting the gas main, and testing the gas main.

- Corrective maintenance: Corrective maintenance is performed to repair leaks and other problems. Corrective maintenance includes tasks such as patching, welding, and replacing damaged sections of pipe.

10. What are the different types of gas main emergencies and how are they handled?

- Gas leaks: Gas leaks can be dangerous and should be reported immediately. Gas leaks can be detected by the sound of escaping gas or by the smell of gas.

- Gas explosions: Gas explosions can be very dangerous and can cause serious injuries or death. Gas explosions can be caused by a variety of factors, such as gas leaks, ignition sources, and structural damage.

- Gas fires: Gas fires can be dangerous and can cause serious injuries or death. Gas fires can be caused by a variety of factors, such as gas leaks, ignition sources, and structural damage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Main Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Main Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gas Main Fitters are responsible for the installation, maintenance, and repair of gas mains, which are the large pipelines that transport natural gas from production facilities to distribution networks. Key job responsibilities include:

1. Installation

Fitters install gas mains by following blueprints and specifications. They dig trenches, lay pipe, and connect it to existing lines. They also install valves, regulators, and other equipment necessary for the safe and efficient operation of the gas main.

2. Maintenance

Fitters perform regular maintenance on gas mains to ensure their integrity and safety. They inspect pipes, valves, and other equipment for leaks, corrosion, or other damage. They also clean and lubricate equipment, and make repairs as needed.

3. Repair

Fitters repair gas mains that have been damaged by construction, weather, or other events. They locate the source of the damage, excavate the area, and repair or replace the damaged pipe. They also restore the area to its original condition.

4. Safety

Fitters must adhere to strict safety regulations when working on gas mains. They must be familiar with the properties of natural gas and the potential hazards associated with it. They must also wear appropriate safety gear and use proper tools and equipment.

Interview Tips

To ace an interview for a Gas Main Fitter position, candidates should be prepared to discuss their experience and skills in the following areas:

1. Technical Skills

Candidates should be proficient in the installation, maintenance, and repair of gas mains. They should have a strong understanding of the properties of natural gas and the potential hazards associated with it. They should also be familiar with the tools and equipment used in the industry.

- Experience installing, maintaining, and repairing gas mains

- Knowledge of the properties of natural gas and the potential hazards associated with it

- Familiarity with the tools and equipment used in the industry

2. Safety

Candidates should be committed to safety and have a strong understanding of the safety regulations that apply to the gas industry. They should be able to identify potential hazards and take steps to mitigate them.

- Commitment to safety

- Strong understanding of the safety regulations that apply to the gas industry

- Ability to identify potential hazards and take steps to mitigate them

3. Teamwork and Communication

Candidates should be able to work effectively as part of a team and communicate clearly with colleagues, supervisors, and customers. They should also be able to build and maintain relationships with other professionals in the industry.

- Ability to work effectively as part of a team

- Strong communication skills

- Ability to build and maintain relationships with other professionals in the industry

4. Physical Fitness

Candidates should be physically fit and able to work in a variety of conditions, including extreme weather. They should be able to lift heavy objects and work in confined spaces.

- Physical fitness

- Ability to work in a variety of conditions, including extreme weather

- Ability to lift heavy objects and work in confined spaces

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gas Main Fitter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!