Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Gas Mask Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Gas Mask Assembler so you can tailor your answers to impress potential employers.

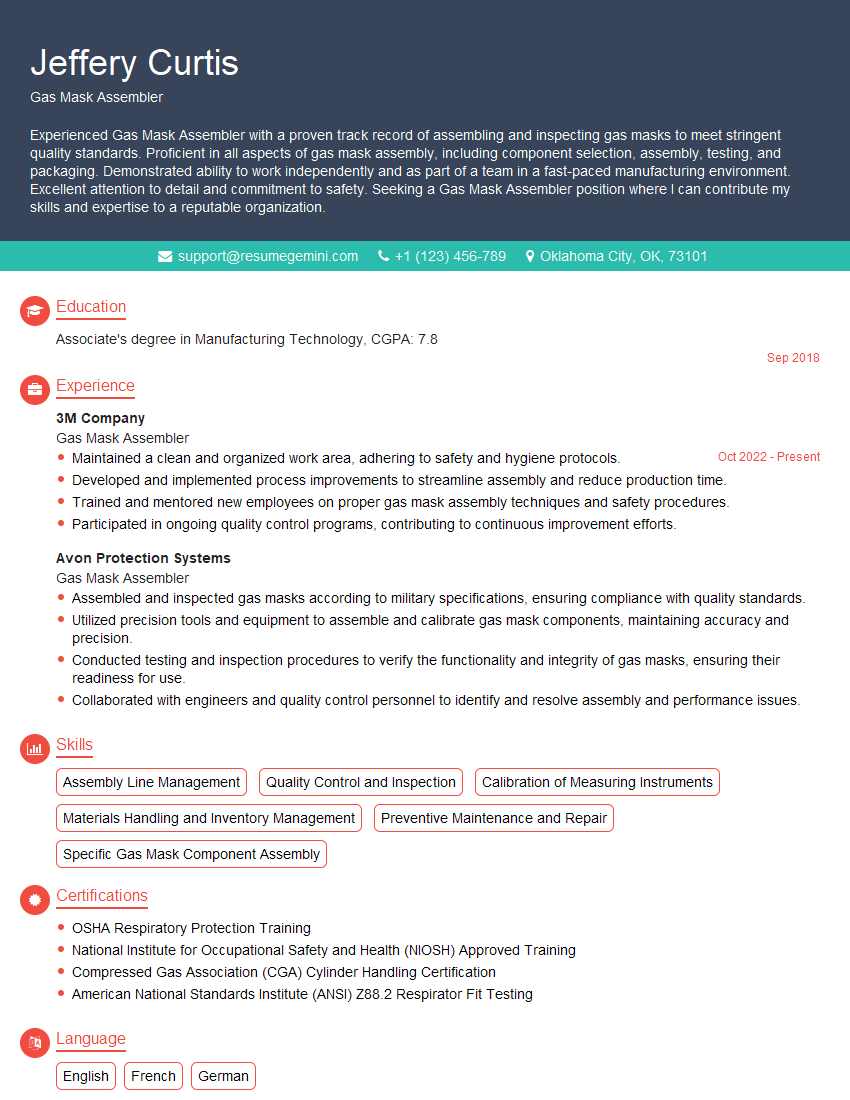

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Mask Assembler

1. Explain the process of assembling a gas mask.

The process of assembling a gas mask involves several steps:

- Inspecting the components for any defects or damage.

- Assembling the facepiece by attaching the lens, exhale valve, and intake valve.

- Attaching the canister to the facepiece.

- Fitting the head harness and adjusting it for a secure fit.

- Conducting a leak test to ensure the mask is properly sealed.

2. What are the different types of gas mask canisters and their uses?

Gas mask canisters are classified based on the types of chemicals they protect against:

Respirator canisters

- Particulate respirators: Protect against dust, fumes, and particles.

- Chemical cartridge respirators: Protect against specific gases and vapors, such as chlorine, ammonia, and hydrogen sulfide.

Canister gas masks

- Single-purpose canisters: Protect against a specific chemical or group of chemicals, such as chlorine or organic vapors.

- Multi-purpose canisters: Protect against a broad range of chemicals, including both organic and inorganic gases and vapors.

3. How do you ensure a proper fit for a gas mask?

Proper fit is crucial for the effectiveness of a gas mask:

- Conduct a fit test by placing the mask on the wearer’s face and applying positive and negative pressure to the facepiece.

- Adjust the head harness straps to achieve a snug but comfortable fit.

- Ensure that the facepiece seals properly around the wearer’s face, without any gaps or leaks.

- Instruct the wearer to move their head and speak to ensure the mask remains in place and does not obstruct their field of vision.

4. What are the storage and maintenance requirements for gas masks?

To ensure the longevity and effectiveness of gas masks:

- Store masks in a cool, dry place away from direct sunlight and extreme temperatures.

- Protect masks from physical damage, such as crushing or impacts.

- Inspect masks regularly for cracks, tears, or other damage.

- Replace the canister when it reaches its end of service life or becomes damaged.

5. Describe the different types of materials used in the construction of gas masks.

Gas masks are constructed from various materials to provide protection and durability:

- Facepieces: Made from materials such as rubber, silicone, or plastic that provide a comfortable seal against the face.

- Canisters: Made from materials that absorb or neutralize specific gases and vapors.

- Head harnesses: Made from adjustable straps to ensure a secure fit.

- Valves: Made from materials that allow the wearer to breathe while preventing contaminated air from entering.

- Filters: Made from materials that remove particles and aerosols from the air.

6. What are the safety precautions to follow when working with gas masks?

To handle gas masks safely:

- Always inspect the mask for damage before use.

- Confirm that the canister is appropriate for the specific hazardous substance(s) present.

- Ensure the mask fits properly and creates a tight seal.

- Never enter a hazardous area without a properly functioning gas mask.

- Follow all manufacturer instructions for use and storage.

7. Explain the quality control procedures involved in gas mask production.

Quality control is essential to ensure the effectiveness and safety of gas masks:

- Regular inspection of raw materials to meet specifications.

- Testing the fit and function of each assembled mask.

- Conducting leak tests to verify the integrity of the mask.

- Documenting the production process and test results.

- Regularly calibrating and maintaining testing equipment.

8. Describe the importance of teamwork in the gas mask assembly process.

Teamwork is crucial for the efficient and accurate production of gas masks:

- Coordinating the flow of materials and components among team members.

- Working together to resolve any issues or challenges that arise during assembly.

- Sharing knowledge and expertise to improve the assembly process.

- Maintaining a safe and organized work environment.

- Communicating effectively to ensure smooth collaboration.

9. How do you stay up-to-date with industry best practices and advancements in gas mask technology?

To stay informed and improve my skills:

- Attending industry conferences and workshops.

- Reading technical publications and research papers.

- Seeking guidance from experienced professionals in the field.

- Participating in training programs offered by manufacturers or industry organizations.

- Exploring online resources and forums related to gas mask technology.

10. How would you prioritize your responsibilities if faced with multiple urgent tasks related to gas mask production?

To prioritize tasks effectively:

- Assess the criticality and deadlines of each task.

- Consider the impact of delays on production and safety.

- Delegate tasks to team members based on their skills and availability.

- Communicate priorities and deadlines clearly to all involved.

- Monitor progress and make adjustments as needed to ensure timely completion.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Mask Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Mask Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities:

Gas Mask Assemblers play a crucial role in ensuring the production of high-quality and reliable respiratory protective equipment.

1. Assembling of Components

Assemble and fit various components of gas masks, including filters, cartridges, valves, and facepieces.

- Adhere strictly to established assembly specifications and quality standards.

- Inspect components for defects and ensure they meet the required specifications.

2. Testing and Inspection

Conduct thorough inspections and functional tests on assembled gas masks.

- Verify the fit and functionality of all components, including valves, filters, and seals.

- Ensure that gas masks meet performance and safety standards.

3. Maintenance and Troubleshooting

Perform regular maintenance and troubleshooting of assembly equipment and tools.

- Identify and resolve issues that may arise during the assembly process.

- Calibrate equipment and maintain a clean and organized work area.

4. Quality Control

Implement quality control measures to ensure the production of high-quality gas masks.

- Monitor assembly processes and identify areas for improvement.

- Provide feedback to management on quality-related issues and recommended solutions.

Interview Tips:

Preparing for an interview as a Gas Mask Assembler requires thorough research and a clear understanding of the job responsibilities.

1. Research the Company and Industry

Gather information about the company’s history, products, and industry trends.

- Visit the company’s website and social media pages to gain insights into their culture and values.

- Read industry publications to understand the latest developments and best practices.

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare your responses to highlight your skills and experience.

- Prepare specific examples of your ability to assemble and test gas masks.

- Discuss your understanding of quality control processes and your experience in troubleshooting assembly issues.

3. Showcase Your Attention to Detail and Precision

Emphasize your meticulous and precise nature, as these are crucial qualities for a Gas Mask Assembler.

- Highlight your experience in working with small and intricate components.

- Explain how you ensure accuracy and consistency in your work.

4. Demonstrate Your Commitment to Safety

Convince the interviewer that you understand the importance of safety in the production of respiratory protective equipment.

- Describe your adherence to safety protocols and regulations.

- Share your experience in working with hazardous materials or in safety-sensitive environments.

Next Step:

Now that you’re armed with the knowledge of Gas Mask Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Gas Mask Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini