Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Gas Pipe Layer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Gas Pipe Layer so you can tailor your answers to impress potential employers.

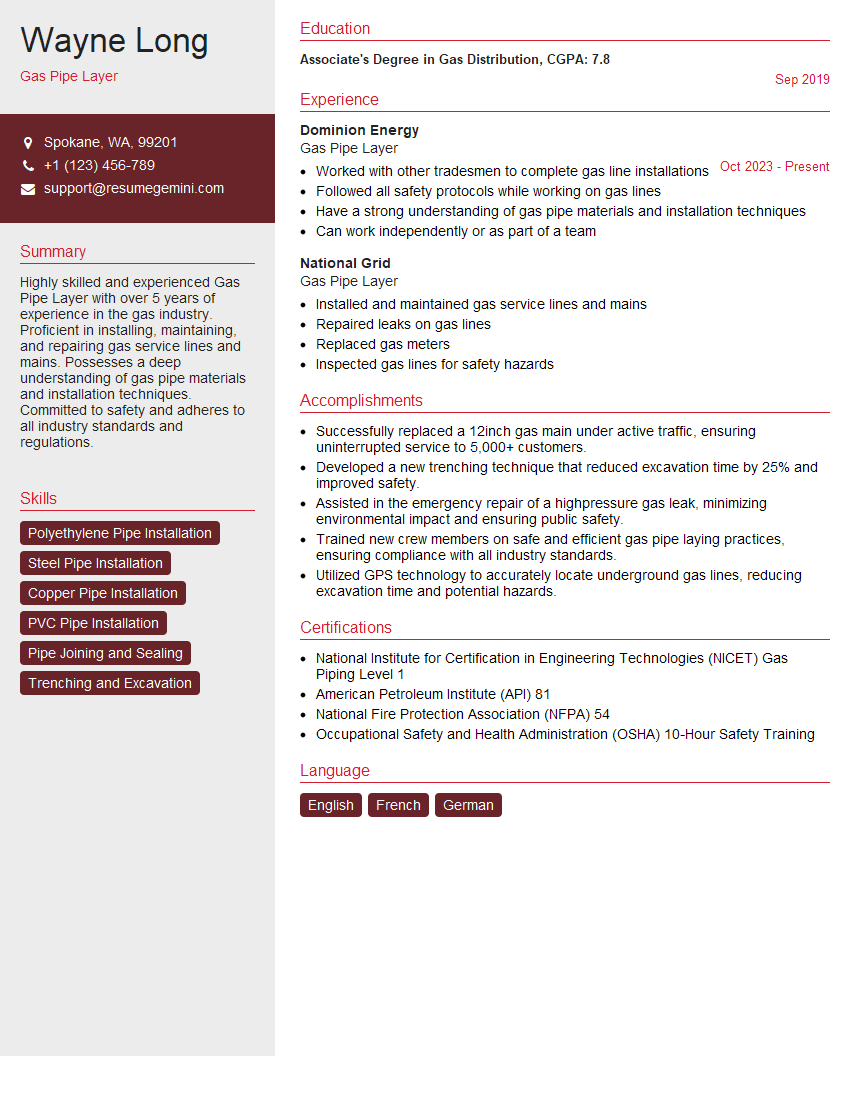

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Pipe Layer

1. Describe the process of trenching for gas pipe installation.

- Plan the trench location and identify any utilities or obstacles.

- Use a trenching machine or manual tools to excavate the trench to the required depth and width.

- Grade the bottom of the trench to ensure proper drainage.

- Install a bedding of sand or gravel to support the pipe.

- Place temporary supports to prevent trench collapse.

2. Explain the different types of gas pipes and their applications.

Polyethylene (PE) pipes

- Lightweight and flexible, making them easy to install.

- Resistant to corrosion and chemicals.

- Used for low-pressure gas distribution.

Steel pipes

- Strong and durable.

- Used for high-pressure gas transmission and distribution.

- Require cathodic protection to prevent corrosion.

3. How do you ensure the proper alignment and fitting of pipes during installation?

- Use a level and measuring tape to check the pipe alignment.

- Measure and cut the pipes to the correct length.

- Join the pipes using appropriate fittings, such as couplings, unions, and elbows.

- Tighten the fittings to the specified torque.

- Check for leaks using a soap solution or a gas detector.

4. What precautions do you take when handling and transporting gas pipes?

- Wear proper protective gear, including gloves and safety glasses.

- Inspect the pipes for damage before handling.

- Use slings or lifting straps to move heavy pipes.

- Protect the pipes from damage during transport.

- Secure the pipes to prevent movement during transport.

5. Discuss the safety procedures for gas pipe installation.

- Obtain necessary permits and follow safety regulations.

- Wear appropriate safety gear, including hard hat, safety glasses, and gloves.

- Inspect the work area for hazards, such as buried utilities or unstable ground.

- Use gas detectors to monitor gas levels.

- Establish proper ventilation to prevent gas accumulation.

6. Explain the importance of proper record-keeping during gas pipe installation.

- Tracks the installation process for future reference.

- Provides documentation for permit approval and inspections.

- Helps identify any potential issues or defects.

- Facilitates maintenance and repairs in the future.

- Protects the company and the gas pipe layer in case of any legal disputes.

7. How do you deal with underground obstacles during trenching?

- Identify the obstacle using detection equipment.

- Plan an alternative trench route if possible.

- Hand-dig around the obstacle carefully.

- Use specialized tools or equipment to remove the obstacle.

- Ensure the stability of the trench and surrounding area.

8. Describe the procedure for testing the integrity of installed gas pipes.

- Perform a hydrostatic pressure test to check for leaks.

- Use an electronic leak detector to identify any gas leaks.

- Conduct a soap bubble test to detect small leaks.

- Document test results and obtain necessary approvals.

- Backfill the trench only after successful testing.

9. What are the common causes of gas pipe leaks and how do you prevent them?

-

Causes:

- Corrosion

- Improper installation

- Physical damage Prevention:

- Use corrosion-resistant materials.

- Install pipes properly according to specifications.

- Protect pipes from external damage using protective coatings or casing.

10. Explain the process of repairing a gas pipe leak.

- Identify and locate the leak using leak detection equipment.

- Excavate the trench to expose the damaged pipe section.

- Cut out the damaged section and install a replacement pipe.

- Weld or join the new pipe section to the existing pipeline.

- Test the repaired section for leaks.

- Backfill the trench and restore the work area.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Pipe Layer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Pipe Layer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gas Pipe Layers are responsible for the installation and repair of underground gas pipelines. They play a crucial role in ensuring a safe and reliable supply of natural gas to homes, businesses, and industries.

1. Pipeline Installation

Laying underground gas pipelines is a complex process that requires precision and expertise.

- Excavate trenches to the required depth and width.

- Assemble and join gas pipes using specialized tools and equipment.

- Lower the assembled pipes into the trenches and align them correctly.

- Backfill and compact the trenches to ensure the stability of the pipelines.

2. Pipeline Maintenance and Repair

Regular maintenance and repairs are essential to ensure the safety and efficiency of gas pipelines.

- Inspect pipelines for corrosion, leaks, or any other damage.

- Repair or replace damaged sections of pipes using appropriate materials and techniques.

- Conduct pressure tests to verify the integrity of repaired pipelines.

- Monitor gas flow and pressure within the pipelines using specialized equipment.

3. Safety and Compliance

Gas Pipe Layers must prioritize safety and comply with all applicable regulations and standards.

- Follow established safety protocols and use personal protective equipment.

- Adhere to building and material codes and industry best practices.

- Obtain necessary permits and clearances before commencing any work.

- Document all activities and findings in detailed reports and logs.

4. Customer Service

Gas Pipe Layers may occasionally interact with customers or residents during their work.

- Provide clear and concise information to customers regarding gas line work.

- Address any concerns or questions raised by customers in a professional and courteous manner.

- Maintain a positive and cooperative relationship with customers throughout the project.

Interview Tips

Preparing thoroughly for a job interview can significantly increase your chances of success. Here are some tips to help you ace your interview as a Gas Pipe Layer:

1. Research the Company and Industry

Learn about the company’s history, mission, values, and current projects. Familiarize yourself with the natural gas industry, including its regulations and safety standards.

- Visit the company’s website and social media pages.

- Read industry publications and articles.

- Network with professionals in the field.

2. Highlight Your Skills and Experience

Review the job description carefully and identify the key skills and experience required. Highlight your relevant qualifications in your resume and during the interview.

- Emphasize your proficiency in pipeline installation and repair techniques.

- Provide specific examples of your safety record and adherence to industry standards.

- Discuss your problem-solving abilities and ability to work in a team.

3. Prepare for Common Interview Questions

Research common interview questions and prepare thoughtful answers that demonstrate your knowledge and skills. Practice answering these questions out loud to improve your delivery.

- Tell me about your experience in gas pipeline installation and repair.

- How do you ensure safety and compliance on the job?

- Describe a challenging project you worked on and how you overcame the obstacles.

4. Ask Informed Questions

Asking well-thought-out questions shows your interest and engagement in the role. Prepare a few questions to ask the interviewer about the company, the position, or the industry.

- Can you elaborate on the company’s safety protocols for gas pipeline work?

- What are the opportunities for professional development and advancement within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gas Pipe Layer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.