Are you gearing up for a career in Gas Pumping Station Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Gas Pumping Station Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

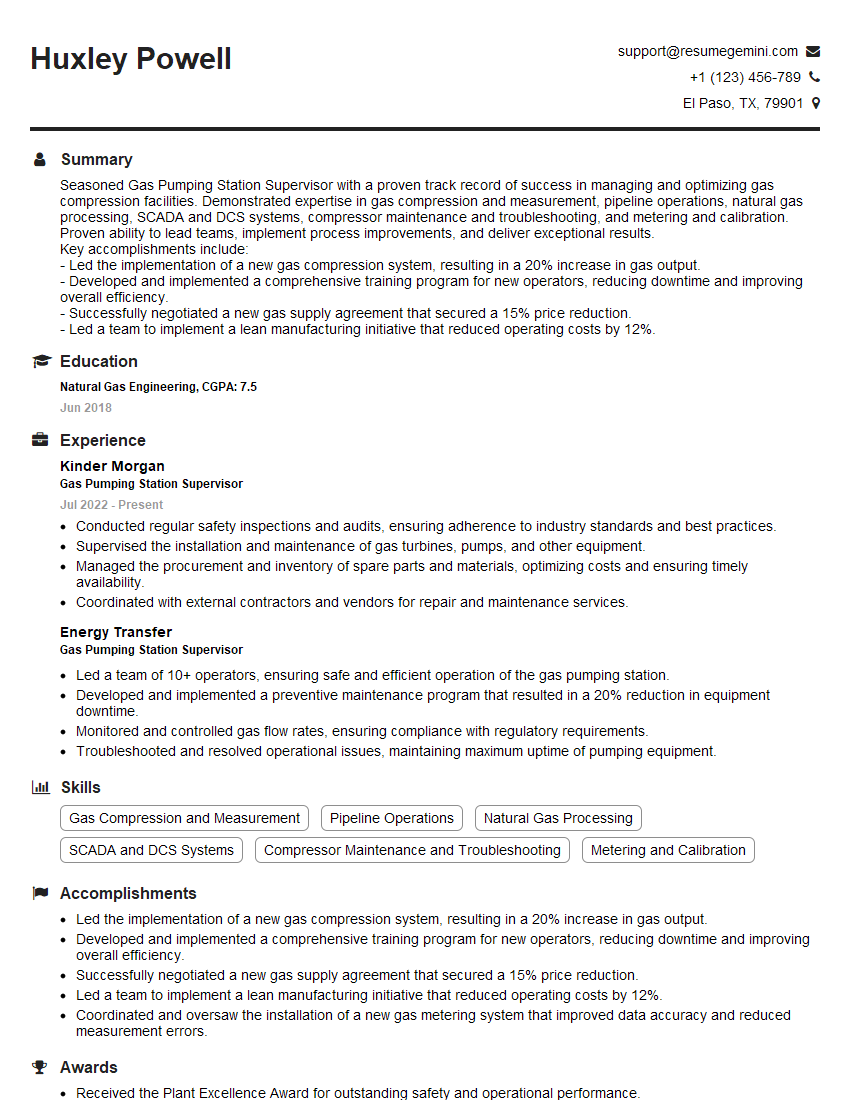

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Pumping Station Supervisor

1. How would you ensure the safe and efficient operation of the gas pumping station?

To ensure the safe and efficient operation of the gas pumping station, I would implement the following measures:

- Conduct regular inspections and maintenance of all equipment and pipelines to prevent potential failures.

- Establish clear operating procedures and ensure that all personnel are trained and adhere to them.

- Implement a comprehensive safety management system that includes hazard identification, risk assessment, and control measures.

- Monitor and control the flow of gas through the station to maintain stable pressure and prevent overloads.

- Coordinate with emergency responders to develop and practice emergency response plans.

2. What are the key performance indicators (KPIs) that you would use to measure the performance of the gas pumping station?

Station Efficiency

- Throughput volume (actual vs. planned)

- Energy consumption per unit of gas pumped

- Equipment uptime and availability

Safety and Environmental Compliance

- Number of safety incidents

- Compliance with environmental regulations

- Spill prevention and response measures

Financial Performance

- Operating costs (including maintenance and labor)

- Revenue generated from gas sales

- Return on investment

3. What steps would you take to optimize the performance of the gas pumping station?

To optimize the performance of the gas pumping station, I would focus on the following areas:

- Equipment optimization: Upgrade or replace outdated equipment with more efficient models, implement predictive maintenance to prevent breakdowns, and optimize equipment settings for maximum performance.

- Process optimization: Analyze the gas flow patterns and identify bottlenecks, implement flow control measures to minimize pressure drops, and optimize the operating pressure to reduce energy consumption.

- Staff training and development: Provide comprehensive training to all personnel on best practices for operating the station safely and efficiently, and encourage continuous professional development.

- Data analysis and performance monitoring: Collect and analyze data on station performance, identify areas for improvement, and make data-driven decisions to optimize operations.

- Collaboration and communication: Foster a collaborative environment where staff can share ideas and work together to identify and implement performance improvements.

4. How would you handle a major gas leak or other emergency situation at the gas pumping station?

In the event of a major gas leak or other emergency situation at the gas pumping station, I would take the following steps:

- Immediate actions: Activate the emergency response plan, secure the area, and notify emergency responders.

- Assessment and containment: Assess the situation, identify the source of the leak or emergency, and implement containment measures to prevent further escalation.

- Communication and coordination: Communicate with emergency responders, regulatory authorities, and the public, providing timely and accurate information.

- Resource mobilization: Mobilize necessary resources, including personnel, equipment, and materials, to address the emergency effectively.

- Recovery and restoration: Once the emergency is under control, initiate recovery and restoration efforts to minimize downtime and restore normal operations as soon as possible.

5. What are the latest technological advancements in gas pumping station operations that you are aware of?

The gas pumping station industry is constantly evolving with new technological advancements. Some of the latest trends and innovations include:

- Remote monitoring and control systems: These systems allow for real-time monitoring and control of station operations from a remote location, enabling increased efficiency and reduced downtime.

- Artificial intelligence (AI) and machine learning (ML): AI and ML algorithms are being used to analyze data, predict equipment failures, and optimize station performance.

- Smart sensors and automation: Smart sensors and automated systems are being deployed to enhance safety, improve reliability, and reduce maintenance costs.

- Renewable energy integration: Gas pumping stations are increasingly integrating renewable energy sources, such as solar and wind power, to reduce their environmental footprint.

- Cybersecurity measures: As gas pumping stations become more connected and automated, cybersecurity measures are becoming increasingly important to protect against cyber attacks.

6. How would you stay up-to-date with the latest industry best practices and regulations for gas pumping station operations?

To stay up-to-date with the latest industry best practices and regulations for gas pumping station operations, I would:

- Attend industry conferences and workshops

- Read industry publications and journals

- Participate in professional organizations and committees

- Network with other professionals in the field

- Stay informed about regulatory changes and updates

7. How would you manage a team of gas pumping station operators and ensure their professional development?

Leadership and Management

- Foster a positive and supportive work environment

- Communicate clear expectations and provide regular feedback

- Delegate responsibilities and empower team members

Professional Development

- Identify training and development needs

- Provide opportunities for on-the-job training

- Encourage employees to pursue professional certifications

- Support employees’ career growth and advancement

8. What are your strengths and weaknesses as they relate to the role of Gas Pumping Station Supervisor?

Strengths- Strong understanding of gas pumping station operations and safety procedures

- Proven ability to lead and motivate a team

- Excellent communication and interpersonal skills

- Experience in managing budgets and resources

- Commitment to continuous improvement and professional development

- Limited experience with some of the latest technological advancements in the industry

- Working on developing stronger time management skills

- Can be too detail-oriented at times

9. Why are you interested in this role and why do you think you are the best candidate?

I am excited about the opportunity to contribute my skills and experience to your organization as a Gas Pumping Station Supervisor. My passion for the industry and my commitment to safety and efficiency make me an ideal candidate for this role.

With my proven ability to lead a team, manage operations, and optimize performance, I am confident that I can make a significant positive impact on your gas pumping station. I am eager to learn from experienced professionals and contribute to the ongoing success of your team.

10. What are your salary expectations for this role?

My salary expectations are commensurate with my experience, qualifications, and the industry average for this role. I am open to discussing a competitive salary package that aligns with the value I can bring to your organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Pumping Station Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Pumping Station Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Gas Pumping Station Supervisor is responsible for the safe, efficient, and reliable operation of a gas pumping station. This individual manages the daily operations of the station, ensuring that all equipment is functioning properly and that the station is meeting its production goals.

1. Safety

The supervisor must have a strong commitment to safety and must ensure that all employees are following proper safety procedures. The supervisor is also responsible for conducting safety drills and training sessions.

- Develop and implement safety protocols and procedures.

- Monitor and enforce adherence to safety regulations.

- Conduct regular safety inspections and audits.

2. Equipment Maintenance

The supervisor is responsible for the maintenance and repair of all equipment at the station. This includes gas compressors, pumps, and other equipment.

- Supervise and coordinate equipment maintenance and repair.

- Troubleshoot and resolve equipment issues.

- Maintain an inventory of spare parts and supplies.

3. Production Management

The supervisor is responsible for ensuring that the station is meeting its production goals. This includes monitoring gas flow rates and pressures, and making adjustments as necessary.

- Monitor and analyze gas flow rates and pressures.

- Adjust equipment settings to optimize production.

- Coordinate with other departments to ensure a smooth flow of gas.

4. Employee Supervision

The supervisor is responsible for supervising all employees at the station. This includes hiring, training, and evaluating employees.

- Supervise and train employees on safety procedures and equipment operation.

- Evaluate employee performance and provide feedback.

- Maintain a positive and productive work environment.

Interview Tips

Preparing for an interview for a Gas Pumping Station Supervisor position can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also help you to answer questions about the position.

- Visit the company website and social media pages.

- Read industry news and articles to learn about current trends.

- Prepare questions to ask the interviewer about the company and the position.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions so that you can deliver them confidently and concisely.

In addition to practicing your answers to common interview questions, it is also helpful to prepare for questions that are specific to the position you are applying for. For example, you may be asked about your experience with gas pumping equipment or your knowledge of safety procedures.

- Use the STAR method to answer interview questions. This involves describing the Situation, Task, Action, and Result of your experience.

- Be specific and provide examples to support your answers.

- Highlight your skills and experience that are relevant to the position.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

It is also important to be on time for your interview. Punctuality shows that you are respectful of the interviewer’s time.

4. Be Enthusiastic and Positive

Employers are looking for candidates who are enthusiastic and positive about their work. Be sure to convey your passion for the gas industry and your desire to work for the company.

It is also important to be positive about yourself and your abilities. Believe in yourself and your ability to do the job.

- Smile and make eye contact with the interviewer.

- Be confident in your abilities and experience.

- Thank the interviewer for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gas Pumping Station Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.