Feeling lost in a sea of interview questions? Landed that dream interview for Gas Torch Brazier but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Gas Torch Brazier interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

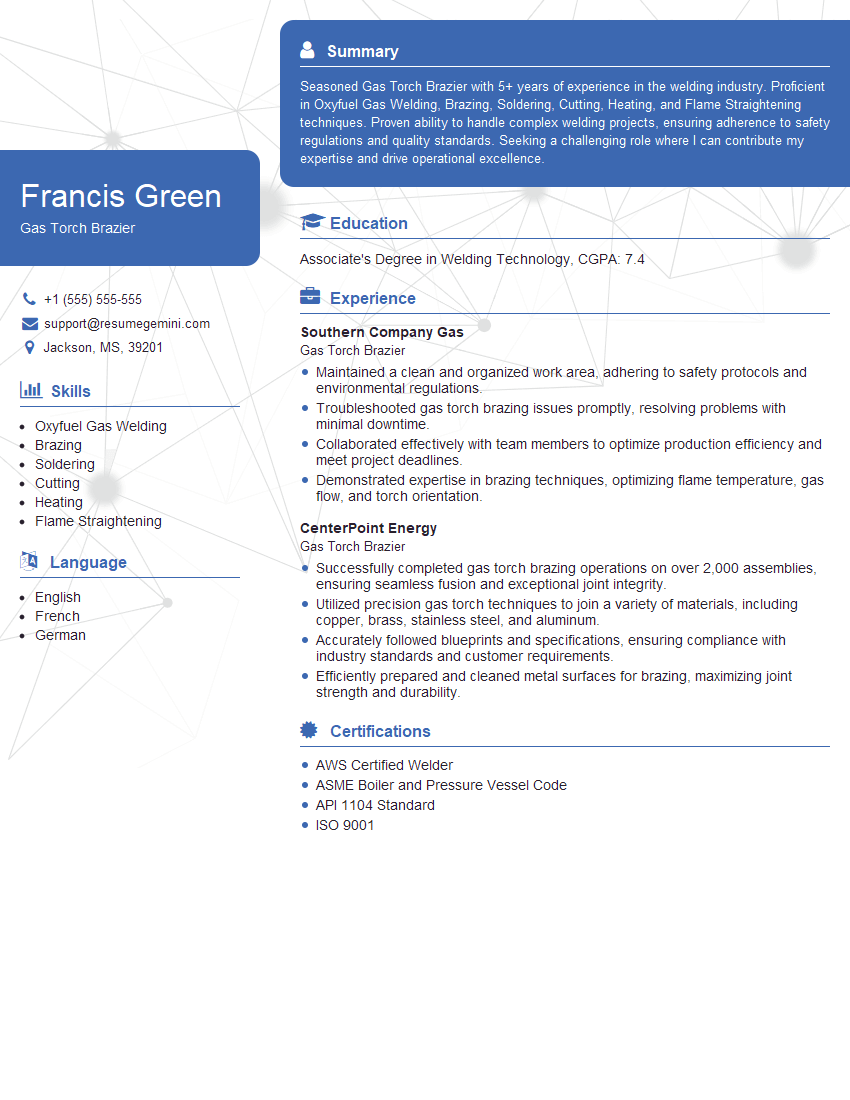

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Torch Brazier

1. What are the key responsibilities of a Gas Torch Brazier?

As a Gas Torch Brazier, my primary responsibilities include:

- Using gas torch to braze and weld metal components

- Inspecting and preparing surfaces before brazing

- Operating and maintaining gas torch equipment

2. What safety precautions do you observe while using a gas torch?

Wearing appropriate safety gear

- Flame-resistant clothing

- Safety glasses

- Welding gloves

Proper ventilation

- Working in well-ventilated areas

- Using exhaust fans to remove fumes

Fire prevention

- Keeping a fire extinguisher nearby

- Clearing work area of flammable materials

- Using fire blankets to smother any flames in case of accidents

3. Explain the process of gas torch brazing

Gas torch brazing involves the following steps:

- Cleaning and preparing the metal surfaces to be joined

- Applying a flux to promote adhesion

- Heating the metal surfaces with the gas torch

- Adding a filler metal to the joint

- Cooling the joint and cleaning any excess filler metal

4. Describe the different types of gas torches used in brazing

- Propane torch: Commonly used for low-temperature brazing

- Acetylene torch: Provides higher temperatures and is suitable for brazing thicker metals

- MAPP gas torch: Offers a versatile flame that is hotter than propane but cooler than acetylene

5. What is the significance of using flux during brazing?

Flux plays a crucial role in brazing by:

- Removing oxides and impurities from the metal surfaces

- Promoting the flow of the filler metal

- Preventing oxidation during the brazing process

6. How do you ensure the quality of brazed joints?

To ensure the quality of brazed joints, I follow these practices:

- Inspecting the surfaces for cleanliness and proper preparation

- Using the correct type and amount of flux

- Maintaining the proper temperature and flame adjustment

- Inspecting the joint for any defects after cooling

7. What are the potential hazards associated with gas torch brazing and how do you mitigate them?

Fires and explosions

- Use fire extinguishers and blankets for emergency situations

- Ensure proper ventilation to prevent gas buildup

Burns

- Wear appropriate safety gear including gloves and protective clothing

- Handle heated materials carefully to avoid contact with skin

Eye damage

- Always wear safety glasses to protect eyes from flying sparks and debris

- Use a welding helmet with the correct shade to prevent glare

8. How do you maintain and troubleshoot gas torch equipment?

Maintenance

- Regularly clean and lubricate equipment

- Inspect hoses for leaks and damage

- Check gas pressure and flow rates

Troubleshooting

- No flame: Check for gas leaks, clogged tips, or faulty ignition

- Weak flame: Adjust gas pressure, clean the tip, or replace the regulator

- Erratic flame: Check for air leaks, hose damage, or a dirty tip

9. How do you stay updated on the latest techniques and best practices in gas torch brazing?

- Attend industry workshops and conferences

- Study and follow industry standards and regulations

- Consult with experienced professionals and manufacturers

10. What qualities make a successful Gas Torch Brazier?

- Excellent hand-eye coordination and manual dexterity

- Strong attention to detail and safety consciousness

- Problem-solving skills and ability to work independently

- Proficiency in using gas torch equipment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Torch Brazier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Torch Brazier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Gas Torch Brazier is responsible for operating and maintaining gas torch brazing equipment to join metal components. They ensure the safe and efficient operation of the equipment, producing high-quality brazed joints.

1. Equipment Operation

Operate gas torch brazing equipment, including torches, regulators, and hoses.

- Set up and adjust equipment according to specifications.

- Monitor equipment performance and make necessary adjustments.

2. Brazing Process

Perform gas torch brazing processes, including joint preparation, fluxing, and heating.

- Prepare metal surfaces for brazing by cleaning and removing oxides.

- Apply flux to the joint area to promote wetting and bonding.

- Heat the joint area using a gas torch and brazing filler metal to create a strong bond.

3. Quality Control

Inspect brazed joints for quality and adherence to specifications.

- Visually examine joints for defects such as cracks, voids, or incomplete bonding.

- Conduct non-destructive testing (e.g., dye penetrant testing) to assess joint integrity.

4. Safety and Maintenance

Follow safety protocols and maintain equipment to ensure a safe work environment.

- Wear appropriate personal protective equipment (PPE), including flame-resistant clothing and gloves.

- Inspect equipment regularly for any damage or leaks.

- Perform routine maintenance and calibration to keep equipment operating efficiently.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some key tips to help you ace your Gas Torch Brazier interview:

1. Research the Company and Position

Gather information about the company’s background, industry, and the specific role you’re applying for. This will demonstrate your interest and enthusiasm for the opportunity.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in gas torch brazing, including equipment operation, joint preparation, and quality control. Quantify your experience with specific examples and metrics whenever possible.

3. Demonstrate Safety Knowledge

Discuss your understanding of safety protocols for gas torch brazing operations. Mention your experience in using PPE, handling hazardous materials, and maintaining equipment safely.

4. Be Prepared to Discuss Technical Concepts

The interviewer may ask technical questions related to gas torch brazing processes. Be ready to explain concepts such as brazing filler metals, fluxing, and joint design. You can also discuss any industry trends or advancements that you are familiar with.

5. Ask Insightful Questions

At the end of the interview, ask thoughtful questions to show your interest and engagement. These questions can be about the company’s growth plans, technological advancements in the industry, or any specific aspects of the role that you’re curious about.

Next Step:

Now that you’re armed with the knowledge of Gas Torch Brazier interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Gas Torch Brazier positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini