Are you gearing up for a career in Gas Torch Solderer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Gas Torch Solderer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

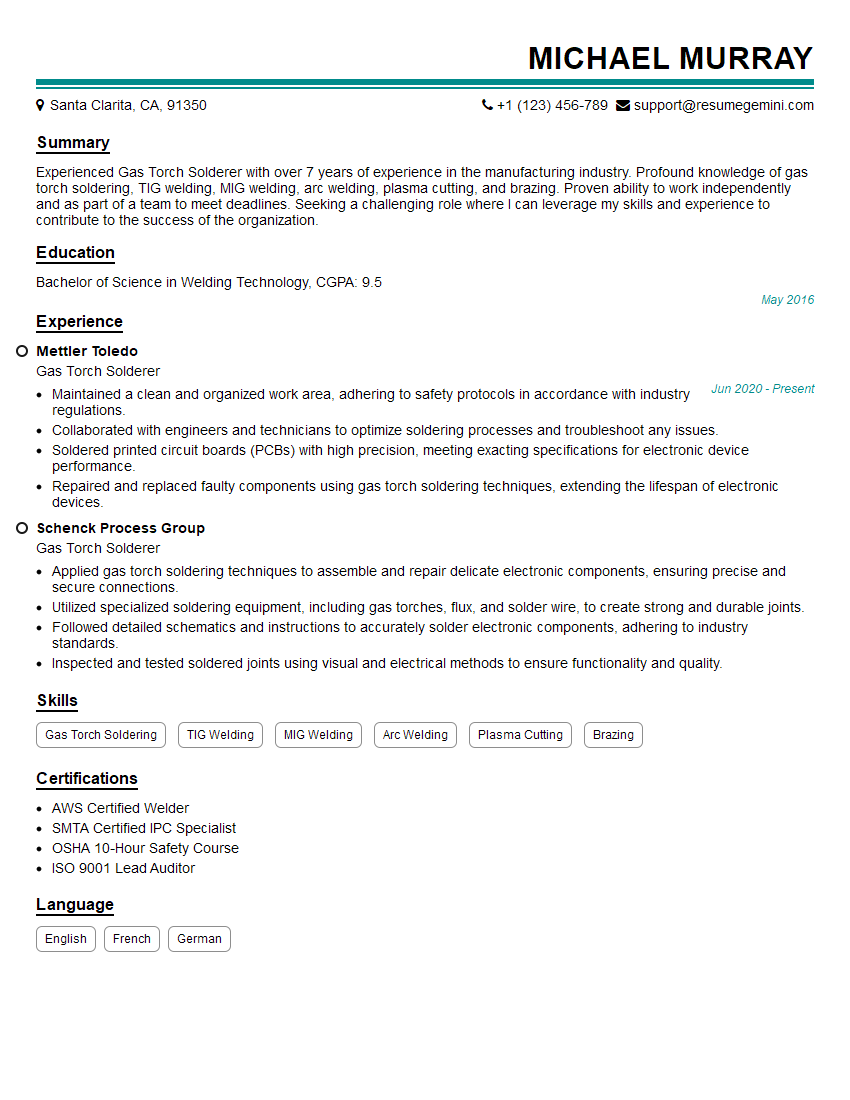

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Torch Solderer

1. Describe the process of gas torch soldering, including the materials and equipment used.

- Gas torch soldering involves joining two metal pieces using a heat source to melt solder, which is a low-melting-point metal alloy.

- The materials used include the metal pieces to be joined, solder, flux, and a gas torch.

2. How do you determine the appropriate size and type of torch tip to use for a particular soldering job?

Tip Size

- The size of the tip should be proportional to the size of the joint being soldered. For example, a larger tip will be needed for a larger joint.

- A larger tip will produce a wider flame that will heat a larger area, while a smaller tip will produce a narrower flame that can be used for more precise work.

Tip Type

- Different tip types are available, such as pointed tips, chisel tips, and spade tips.

- The type of tip chosen should depend on the specific soldering application. For example, a pointed tip is good for fine work, while a chisel tip is better for larger joints.

3. What are the safety precautions that must be observed when using a gas torch for soldering?

- Ensure the work area is well-ventilated to avoid inhaling harmful fumes.

- Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses.

- Keep the gas torch in good working condition, including regular maintenance.

- Never point the torch at anyone or anything flammable.

- Always keep a fire extinguisher nearby in case of emergencies.

4. How do you troubleshoot common soldering problems, such as cold joints and solder bridges?

Cold Joints

- Cold joints occur when the solder does not fully melt and bond the metal pieces together.

- Possible causes include insufficient heat, dirty or oxidized surfaces, or incorrect solder type.

Solder Bridges

- Solder bridges occur when excess solder flows between two or more metal pieces, creating an unintended electrical connection.

- Possible causes include using too much solder, improper torch technique, or misaligned components.

5. What techniques can be employed to achieve a high-quality soldered joint?

- Properly clean and prepare the surfaces to be joined.

- Apply flux to the surfaces to remove oxides and improve solderability.

- Use the appropriate solder and flux for the specific application.

- Apply the solder to the joint while it is still hot.

- Allow the solder to cool and solidify before moving the joint.

6. Describe the different types of solder and their applications.

- Lead-based solders: Most commonly used, provide good electrical and mechanical properties.

- Lead-free solders: Becoming more prevalent due to environmental concerns, but may have different melting points and require higher temperatures.

- Rosin-core solders: Contain a rosin flux in the core, facilitating solderability and cleaning.

7. How do you determine if a soldered joint has passed an electrical continuity test?

- Use a multimeter to check for continuity between the two metal pieces joined.

- If the multimeter beeps or shows a low resistance reading, the joint has electrical continuity.

- If the multimeter does not beep or shows a high resistance reading, the joint has failed the test.

8. What is the proper storage and handling of gas cylinders used for soldering?

- Store cylinders upright in a cool, well-ventilated area.

- Secure cylinders to prevent falling or tipping over.

- Keep cylinders away from sources of ignition and heat.

- Inspect cylinders regularly for leaks or damage.

9. Describe the maintenance procedures for a gas torch used in soldering.

- Inspect the torch regularly for leaks or damage.

- Clean the torch nozzle and tip as needed.

- Lubricate moving parts regularly.

- Check the gas pressure and adjust if necessary.

10. What are the potential hazards associated with using a gas torch for soldering, and how can they be mitigated?

- Fire hazard: Use in well-ventilated areas, keep away from flammable materials, and have a fire extinguisher readily available.

- Eye injury: Wear safety glasses to protect eyes from sparks and molten solder.

- Burns: Wear gloves and keep hands away from hot surfaces.

- Fumes: Use in well-ventilated areas to avoid inhaling harmful fumes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Torch Solderer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Torch Solderer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Gas Torch Solderer plays an essential role in various industries by joining metal components together using a gas torch and solder. The key responsibilities of a Gas Torch Solderer encompass a wide range of tasks, including:

1. Solder Metal Components

The primary responsibility involves using a gas torch to heat and solder metal components to form secure and durable bonds. This task requires precision and attention to detail to ensure that the joints are properly sealed and free from defects.

2. Prepare and Clean Surfaces

Before soldering, the Gas Torch Solderer must prepare the metal surfaces by cleaning and removing any contaminants or impurities. This involves using appropriate tools and techniques to ensure that the solder can adhere properly and create a strong bond.

3. Inspect and Test Soldered Joints

Once the soldering is complete, the Gas Torch Solderer must inspect the joints visually and perform tests to verify their strength and integrity. This may involve using non-destructive testing methods to detect any flaws or imperfections in the joints.

4. Maintain Equipment and Tools

To ensure optimal performance and safety, the Gas Torch Solderer is responsible for maintaining and calibrating the gas torch and other tools used in the soldering process. This includes regular cleaning, lubrication, and adjustment of equipment to prevent malfunctions and ensure efficient operation.

Interview Tips

To ace an interview for a Gas Torch Solderer position, candidates should focus on highlighting their skills and experience in the following areas:

1. Technical Skills

Interviews should emphasize their proficiency in using gas torches, soldering techniques, and testing equipment. They should also demonstrate a strong understanding of the different types of solder and fluxes used in the industry.

2. Attention to Detail

The interviewer should stress their ability to work meticulously and pay close attention to detail. The job requires a keen eye for identifying defects and ensuring that soldered joints meet the required specifications.

3. Safety Consciousness

Candidates should highlight their commitment to safety and knowledge of industry best practices. They should demonstrate an understanding of the potential hazards associated with working with gas torches and hot materials and be able to articulate the measures they take to mitigate risks.

4. Problem-Solving Abilities

The interviewer should showcase their ability to identify and solve problems that may arise during the soldering process. They should provide examples of how they have overcome challenges and maintained productivity while ensuring the quality of their work.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gas Torch Solderer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!