Are you gearing up for an interview for a Gas Welding Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Gas Welding Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

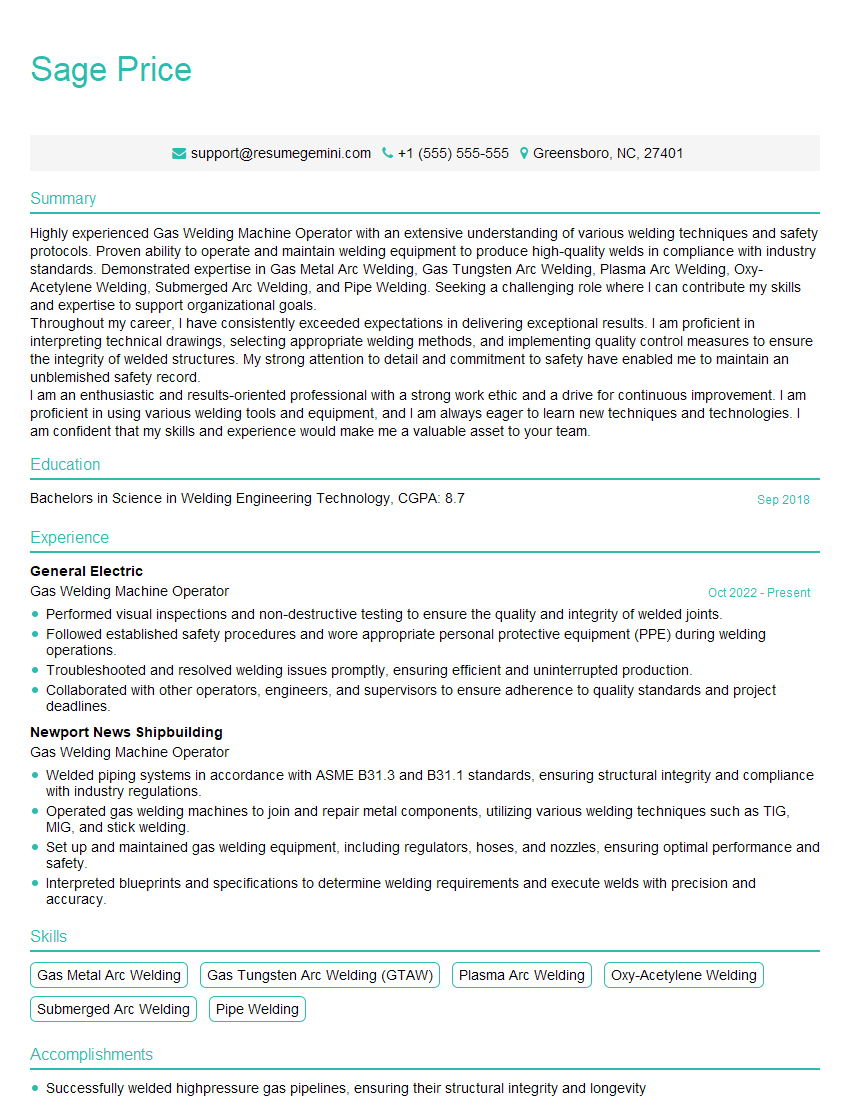

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Welding Machine Operator

1. Explain the basic principles of gas welding.

Gas welding involves combustion of a fuel gas (such as acetylene, propane, or natural gas) with oxygen to produce a high-temperature flame that melts and fuses metal workpieces together.

- The fuel gas provides the heat and the oxygen provides the necessary oxidation reaction for the welding process.

- The flame characteristics, such as temperature and shape, can be adjusted by varying the fuel gas and oxygen flow rates.

2. What are the different types of gas welding torches?

- Neutral flame torch: Produces a flame with equal proportions of fuel gas and oxygen, resulting in a neutral flame that is suitable for welding most metals.

- Oxidizing flame torch: Delivers a flame with an excess of oxygen, resulting in a hotter and more oxidizing flame that is suitable for welding metals that require more oxidation, such as copper and brass.

- Reducing flame torch: Provides a flame with an excess of fuel gas, resulting in a cooler and less oxidizing flame that is suitable for welding metals that are prone to oxidation, such as aluminum.

3. Describe the proper setup and safety procedures for gas welding equipment.

- Ensure a well-ventilated area and secure the gas cylinders in an upright position.

- Attach the correct gas regulators to the cylinders and adjust the pressure according to the manufacturer’s recommendations.

- Connect the torch and hoses to the regulators and check for any leaks.

- Wear appropriate personal protective equipment (PPE), including flame-resistant clothing, gloves, and safety glasses.

- Keep the work area clear of flammable materials and have a fire extinguisher nearby.

- Never leave the equipment unattended while in use.

Setting Up:

Safety Procedures:

4. Explain the different types of welding joints and when to use each type.

- Butt joint: Used when two pieces of metal are joined end-to-end, requiring a clean and square cut.

- Edge joint: Similar to a butt joint, but the metal pieces are joined along their edges.

- Corner joint: Used to join two pieces of metal at a 90-degree angle, forming a corner.

- T-joint: Used to join a flat piece of metal to a round or curved piece.

5. What are the common welding defects and how can they be prevented?

- Porosity: Gas bubbles trapped in the weld metal, which can be prevented by proper shielding gas flow and using clean welding materials.

- Undercut: Groove along the edges of the weld caused by excessive heat input, which can be prevented by maintaining proper welding parameters.

- Cold lap: Unfused or partially fused metal at the joint, which can be prevented by proper joint preparation and adequate preheating.

- Cracks: Fractures in the weld metal, which can be prevented by using the correct welding procedure and avoiding stress concentration points.

6. Describe your experience with different welding materials and their properties.

I have experience working with a range of welding materials, including:

- Steel: Carbon steel, stainless steel, and alloy steel with different tensile strengths and corrosion resistance properties.

- Aluminum: Low-density material with good corrosion resistance and weldability.

- Copper: Excellent electrical and thermal conductivity, requiring proper fluxing and shielding during welding.

7. How do you troubleshoot common gas welding problems, such as backfire or gas leaks?

- Check for incorrect gas mixture or flow rates.

- Inspect the torch tip for clogging or damage.

- Inspect all hose connections and regulators for leaks.

- Tighten any loose fittings or replace damaged hoses.

Backfire:

Gas leaks:

8. Describe your experience with non-destructive testing methods used for welds.

I have experience with the following non-destructive testing (NDT) methods:

- Visual inspection: Examining welds for visible defects using magnifying glasses or borescopes.

- Dye penetrant testing: Applying a dye to the weld to reveal surface cracks or discontinuities.

- Magnetic particle testing: Using magnetic particles to detect surface and subsurface cracks.

9. How do you ensure the quality and consistency of welds?

- Following established welding procedures and specifications.

- Using calibrated welding equipment and regularly maintaining it.

- Performing regular quality checks and inspections.

- Seeking feedback and training to improve techniques.

10. Can you explain the importance of proper joint preparation for gas welding?

Proper joint preparation is crucial for creating strong and reliable welds. It involves:

- Cleaning the joint surfaces to remove dirt, rust, or other contaminants.

- Beveling or grooving the joint edges to provide better penetration and fusion.

- Ensuring proper alignment of the joint to prevent misalignment or undercut.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Welding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Welding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gas Welding Machine Operators are responsible for a range of critical tasks that contribute to the efficient and effective functioning of a manufacturing facility. Here are some key responsibilities that employers typically look for when hiring for this role:

1. Welding

The primary responsibility of a Gas Welding Machine Operator is to weld metal components together using gas welding equipment. This involves setting up the welding machine, selecting the appropriate welding technique and parameters, and skillfully manipulating the welding torch to create strong and durable welds.

- Adjust welding machine settings based on material thickness and type.

- Select and change welding tips and nozzles as required.

- Interpret welding blueprints and specifications to determine welding requirements.

2. Quality Control

Gas Welding Machine Operators are responsible for ensuring the quality of their welds. This involves inspecting welds for defects such as cracks, porosity, and undercuts. They also perform tests such as tensile strength and hardness tests to verify the integrity of the welds.

- Inspect welds for defects using visual and non-destructive testing methods.

- Perform quality control tests to verify weld strength and integrity.

- Maintain accurate records of welding parameters and quality control results.

3. Safety and Maintenance

Gas Welding Machine Operators must adhere to strict safety protocols to prevent accidents and ensure the safe operation of welding equipment. They are also responsible for maintaining their welding equipment in good working condition.

- Follow safety procedures and wear appropriate personal protective equipment.

- Inspect and maintain welding equipment to ensure proper functionality.

- Troubleshoot and repair welding equipment as needed.

4. Collaboration

Gas Welding Machine Operators often work as part of a team and collaborate with other tradespeople to complete projects efficiently. They may be required to provide input on welding techniques and quality control measures, and to assist with other tasks as needed.

- Collaborate with engineers and designers to determine welding specifications.

- Work effectively as part of a team to complete projects on time and within budget.

- Assist with other tasks as assigned, such as material handling or fabrication.

Interview Tips

Preparing thoroughly for a Gas Welding Machine Operator interview can significantly increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific position you’re interviewing for. This will help you understand the company’s culture, values, and the specific requirements of the role. You can use the company’s website, LinkedIn, and other online resources to gather information.

- Identify the company’s mission, vision, and core values.

- Learn about the company’s products or services and their target market.

- Review the job description carefully and identify the key skills and qualifications required.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare your answers in advance. This will help you feel more confident and prepared during the interview. Some common questions you might encounter include:

- “Tell me about your experience as a Gas Welding Machine Operator.”

- “Describe a time when you had to troubleshoot a welding problem.”

- “How do you ensure the quality of your welds?”

3. Highlight Your Skills and Experience

During the interview, make sure to highlight your skills and experience that are relevant to the position. Use specific examples to demonstrate your proficiency in welding techniques, quality control, and safety procedures. Quantify your accomplishments whenever possible to provide concrete evidence of your contributions.

- Provide specific examples of welding projects you’ve worked on.

- Describe the quality control measures you implemented and the results you achieved.

- Explain how you ensured the safety of yourself and others while working with welding equipment.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. It also gives you an opportunity to clarify any information and demonstrate your knowledge of the industry. Some good questions to ask include:

- “What are the current welding projects that the company is working on?”

- “What are the company’s plans for future growth and expansion?”

- “What opportunities are there for professional development and advancement within the company?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gas Welding Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!