Feeling lost in a sea of interview questions? Landed that dream interview for Gasket Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Gasket Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

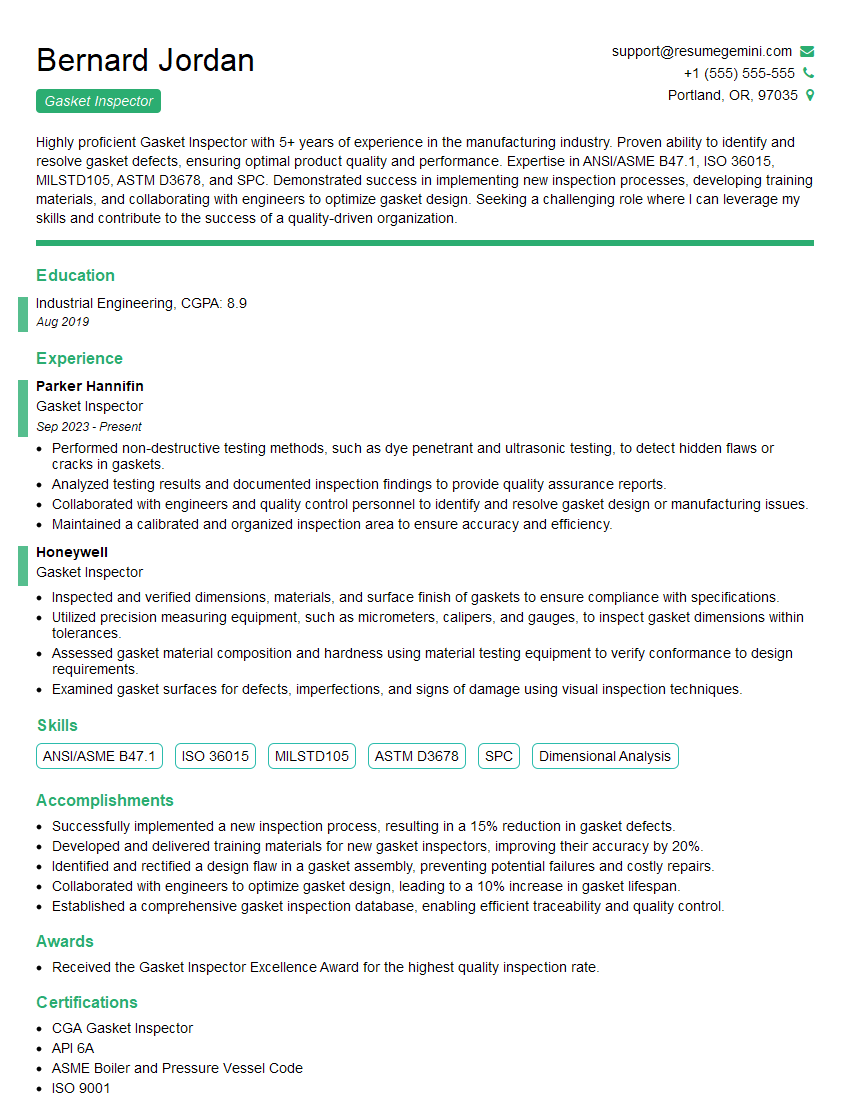

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gasket Inspector

1. What are the different types of gaskets you have inspected and what are their specific applications?

In my previous role, I inspected a wide variety of gaskets, including:

- Flat gaskets: These are thin, sheet-like gaskets that are used to seal between two flat surfaces, such as a flange and a housing.

- O-rings: These are circular gaskets with a round cross-section that are used to seal between cylindrical surfaces, such as a shaft and a housing.

- Gaskets with metal inserts: These gaskets have a metal insert, such as a wire mesh or a perforated plate, that provides additional strength and rigidity.

2. What are the different materials used in gasket manufacturing and what are their properties?

Elastomers

- Nitrile (NBR): Excellent resistance to oil and fuel.

- Neoprene (CR): Good resistance to weather and ozone.

- Silicone (VMQ): High temperature resistance and good flexibility.

Plastics

- Polyethylene (PE): Good chemical resistance and low friction.

- Polytetrafluoroethylene (PTFE): Excellent chemical resistance and high temperature resistance.

3. What are the common defects found in gaskets and how do you identify them?

Common defects in gaskets include:

- Cuts and tears: These can be caused by improper handling or installation.

- Foreign objects: These can become trapped in the gasket during manufacturing or installation.

- Incorrect size or shape: These can lead to leaks or other problems.

- Material defects: These can include voids, cracks, or delamination.

I use a variety of methods to identify defects, including visual inspection, dimensional measurement, and material testing.

4. What are the different inspection techniques used for gaskets and what are their advantages and disadvantages?

The different inspection techniques used for gaskets include:

- Visual inspection: This is a simple and inexpensive method that can be used to identify defects such as cuts, tears, and foreign objects.

- Dimensional measurement: This method is used to verify that the gasket is the correct size and shape.

- Material testing: This method is used to assess the material properties of the gasket, such as its strength, flexibility, and resistance to chemicals and temperature.

5. What are the quality control procedures you follow when inspecting gaskets?

The quality control procedures I follow when inspecting gaskets include:

- Visual inspection: I carefully examine the gasket for any defects, such as cuts, tears, or foreign objects.

- Dimensional measurement: I use a micrometer or other measuring tool to verify that the gasket is the correct size and shape.

- Material testing: I perform material tests, such as tensile strength testing and elongation testing, to assess the material properties of the gasket.

6. What are the common industry standards for gasket inspection?

The common industry standards for gasket inspection include:

- ASTM D4330: Standard Practice for Rubber Gaskets

- ISO 3601-1: Rubber gaskets – Part 1: Inspection and acceptance criteria

- ASME B16.21: Non-Metallic Gaskets for Pipe Flanges

These standards provide guidelines for the inspection of gaskets, including the types of defects to look for, the inspection methods to use, and the acceptance criteria.

7. What are the latest advancements in gasket inspection technology?

The latest advancements in gasket inspection technology include:

- Automated visual inspection: This technology uses cameras and image processing software to automatically inspect gaskets for defects.

- Non-destructive testing: This technology uses techniques such as ultrasonic testing and radiographic testing to inspect gaskets for defects without damaging them.

These advancements are helping to improve the efficiency and accuracy of gasket inspection.

8. How do you stay up-to-date on the latest industry trends and best practices for gasket inspection?

I stay up-to-date on the latest industry trends and best practices for gasket inspection by:

- Attending industry conferences and workshops.

- Reading industry publications and technical journals.

- Participating in online forums and discussion groups.

I am also a member of the American Society for Nondestructive Testing (ASNT) and the International Society of Automation (ISA).

9. How do you handle discrepancies between your inspection results and the manufacturer’s specifications?

If I find a discrepancy between my inspection results and the manufacturer’s specifications, I will:

- Verify my inspection results.

- Contact the manufacturer to discuss the discrepancy.

- Work with the manufacturer to resolve the discrepancy.

I will also document the discrepancy and the steps taken to resolve it.

10. What is your approach to continuous improvement in your role as a Gasket Inspector?

I am always looking for ways to improve my skills and knowledge as a Gasket Inspector. I regularly review my inspection procedures and make adjustments as needed. I also seek out opportunities to learn new techniques and technologies.

In addition, I am always open to feedback from my colleagues and supervisors. I use this feedback to identify areas where I can improve my performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gasket Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gasket Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gasket Inspectors play a critical role in ensuring the quality and integrity of gasket products. Their primary responsibilities encompass:

1. Inspecting Gaskets for Defects

Inspectors thoroughly examine gaskets for any flaws, such as cracks, tears, burrs, or dimensional inaccuracies.

- Utilizing visual inspection techniques and measuring instruments to identify deviations from established standards.

- Operating specialized equipment, such as optical comparators or coordinate measuring machines, to ensure precise measurements.

2. Ensuring Dimensional Accuracy

Inspectors verify that gasket dimensions meet specified tolerances.

- Measuring and comparing gasket dimensions against blueprints or technical specifications.

- Employing calipers, micrometers, or precision measuring tools to obtain accurate readings.

3. Evaluating Material Properties

Inspectors assess the physical and chemical properties of gasket materials to ensure they meet industry standards.

- Performing tests, such as hardness, tensile strength, and chemical resistance analysis, to evaluate material quality.

- Utilizing knowledge of material properties to determine the suitability of gaskets for specific applications.

4. Maintaining Inspection Records

Inspectors maintain detailed records of all inspections, including the results, any discrepancies identified, and corrective actions taken.

- Documenting inspection findings in written reports or electronic databases.

- Preserving records for quality control and traceability purposes.

Interview Tips

To ace your Gasket Inspector interview, follow these preparation tips and showcase your skills and knowledge:

1. Research the Industry and Company

Familiarize yourself with the gasket manufacturing industry, the company’s products, and its reputation in the market.

- Visit the company’s website to gain insights into its operations and quality standards.

- Read industry publications to stay updated on the latest trends and advancements in gasket inspection.

2. Highlight Your Inspection Skills

Emphasize your expertise in inspection techniques, including visual inspection, dimensional measurement, and material testing.

- Provide specific examples of complex or challenging inspections you have successfully conducted.

- Describe the tools and equipment you are proficient in operating.

3. Demonstrate Your Attention to Detail

Showcase your sharp eye for detail and ability to identify even minor defects in gaskets.

- Explain how you approach inspections systematically and thoroughly.

- Share examples of how your attention to detail has contributed to the detection and resolution of quality issues.

4. Emphasize Your Understanding of Gasket Materials

Display your knowledge of different gasket materials and their properties, including their suitability for specific applications.

- Describe the factors that influence the selection of gasket materials.

- Discuss the importance of understanding the chemical and physical properties of gaskets.

5. Prepare for Technical Questions

Review common technical questions related to gasket inspection, such as:

- What are the different types of gasket defects you have encountered?

- How do you calibrate inspection equipment to ensure accuracy?

- What is your approach to evaluating the performance of gaskets under different conditions?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Gasket Inspector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Gasket Inspector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.