Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gasket Winder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

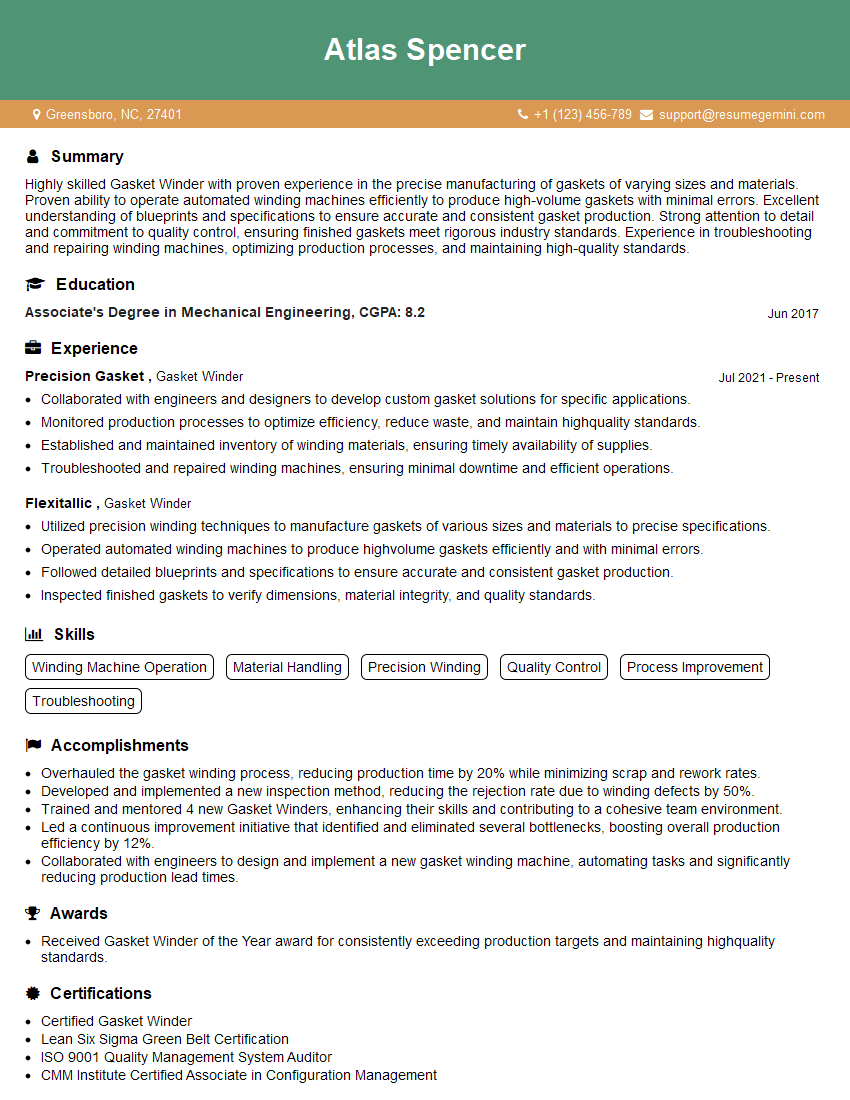

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gasket Winder

1. Explain the process of winding a gasket on a winding machine?

- Firstly, the winding machine is set up with the appropriate winding parameters, such as the winding speed, tension, and number of turns.

- The gasket material is then loaded onto the winding machine.

- The winding machine then starts winding the gasket material onto the core.

- The winding machine continues winding the gasket material until the desired number of turns is reached.

- The winding machine then cuts the gasket material and removes it from the core.

2. What are the different types of winding machines used for gaskets?

Semi-automatic winding machines

- These machines require an operator to load the gasket material onto the machine and to start the winding process.

- The machine then automatically winds the gasket material onto the core.

Fully-automatic winding machines

- These machines do not require an operator to load the gasket material onto the machine or to start the winding process.

- The machine automatically loads the gasket material onto the core and starts the winding process.

3. What are the key factors to consider when selecting a winding machine for gaskets?

- The type of gasket material being wound. Some winding machines are better suited for winding certain types of gasket materials than others.

- The size and shape of the gasket being wound. The winding machine must be able to accommodate the size and shape of the gasket being wound.

- The winding speed required. The winding machine must be able to wind the gasket at the desired speed.

- The accuracy required. The winding machine must be able to wind the gasket with the desired accuracy.

- The cost of the winding machine. The winding machine must be affordable for the application.

4. What are the common problems that can occur during the winding process and how can they be prevented?

- Gasket material tension issues. Gasket material tension can cause the gasket to wind unevenly or to break.

- Core alignment issues. Core alignment issues can cause the gasket to wind crookedly.

- Winding speed issues. Winding speed issues can cause the gasket to wind too quickly or too slowly.

- Accuracy issues. Accuracy issues can cause the gasket to be wound with the wrong dimensions.

5. What are the different types of gaskets that can be wound on a winding machine?

- Flat gaskets. Flat gaskets are used to seal flat surfaces.

- O-rings. O-rings are used to seal circular surfaces.

- V-rings. V-rings are used to seal V-shaped surfaces.

- U-rings. U-rings are used to seal U-shaped surfaces.

6. What are the different materials used to make gaskets?

- Rubber. Rubber is a common material used to make gaskets because it is flexible and can seal a wide variety of surfaces.

- Cork. Cork is a natural material that is used to make gaskets because it is compressible and can seal uneven surfaces.

- Metal. Metal is a strong material that is used to make gaskets that can withstand high pressures and temperatures.

- Plastic. Plastic is a lightweight material that is used to make gaskets that are resistant to chemicals and corrosion.

7. What are the different applications for gaskets?

- Automotive. Gaskets are used in automotive engines, transmissions, and other components to seal fluids and gases.

- Industrial. Gaskets are used in industrial machinery to seal fluids, gases, and other substances.

- Aerospace. Gaskets are used in aerospace applications to seal fluids, gases, and other substances in high-pressure and high-temperature environments.

- Medical. Gaskets are used in medical devices to seal fluids, gases, and other substances.

8. What are the different quality control procedures used for gaskets?

- Visual inspection. Visual inspection is used to check for defects such as cracks, tears, and burrs.

- Dimensional inspection. Dimensional inspection is used to check for the correct dimensions of the gasket.

- Leak testing. Leak testing is used to check for leaks in the gasket.

- Pressure testing. Pressure testing is used to check for the ability of the gasket to withstand high pressures.

9. What are the different safety precautions that must be taken when working with winding machines?

- Wear appropriate safety gear. This includes safety glasses, gloves, and ear protection.

- Keep the work area clean and free of debris.

- Be aware of the moving parts of the winding machine.

- Do not operate the winding machine if it is not in good working condition.

- Follow all manufacturer’s instructions for the winding machine.

10. What are the different troubleshooting techniques that can be used for winding machines?

- Check the power supply. Make sure that the winding machine is plugged into a power outlet and that the power switch is turned on.

- Check the winding tension. Make sure that the winding tension is set correctly for the type of gasket material being wound.

- Check the core alignment. Make sure that the core is aligned correctly with the winding head.

- Check the winding speed. Make sure that the winding speed is set correctly for the type of gasket material being wound.

- Check the accuracy of the winding. Make sure that the gasket is being wound with the correct dimensions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gasket Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gasket Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gasket Winders are responsible for operating winding machines that produce gaskets for various industrial applications. These gaskets are crucial components for engines, pumps, and other equipment, and therefore, the key job responsibilities of a Gasket Winder involve performing tasks with precision and attention to detail.

1. Machine Operation

A Gasket Winder’s primary duty is to handle and operate winding machines efficiently. This includes setting up the machine, monitoring its operation, and making necessary adjustments to ensure smooth production.

- Loading raw materials (gasket material) into the machine

- Selecting the appropriate winding parameters based on gasket specifications

- Monitoring the winding process to ensure gasket dimensions and quality meet requirements

2. Quality Control

Gasket Winders are responsible for maintaining high-quality standards in gasket production. They perform regular inspections and tests to ensure that gaskets meet the required specifications.

- Checking gasket dimensions and tolerances using measuring tools

- Conducting leak tests to verify gasket sealing performance

- Maintaining records of quality checks and gasket specifications

3. Maintenance and Troubleshooting

To ensure optimal machine performance, Gasket Winders perform routine maintenance and troubleshooting tasks. They clean and lubricate the machinery, identify and resolve any operational issues, and coordinate repairs with maintenance personnel as needed.

- Cleaning and lubricating winding machines

- Diagnosing and resolving mechanical or electrical problems

- Reporting any major issues or repairs to supervisors

4. Safety and Compliance

Gasket Winders adhere to safety regulations and comply with established quality standards in the workplace. They wear appropriate protective gear, follow safety procedures, and maintain a clean and organized work environment.

- Wearing protective gear such as gloves, safety glasses, and earplugs

- Following established safety protocols

- Maintaining a clean and organized work area

Interview Tips

Preparing thoroughly for the interview is essential to showcase your skills and qualifications as a Gasket Winder. Here are some interview tips to help you ace the interview:

1. Research the Company and Position

Demonstrate your interest in the company and the Gasket Winder position by researching their website, industry reputation, and specific job requirements. This knowledge will help you tailor your answers and ask insightful questions during the interview.

- Visit the company website to learn about their products, services, and culture

- Review industry publications and news articles to stay informed about the latest trends

- Study the job description carefully to identify the key skills and experience required

2. Practice Your Answers

Prepare for common interview questions by practicing your answers. This will boost your confidence and enable you to articulate your skills and experience effectively. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples.

- Anticipate questions related to your experience with winding machines, quality control, and troubleshooting

- Use the STAR method to highlight your skills and achievements

- Rehearse your answers out loud to improve your delivery

3. Highlight Your Relevant Skills and Experience

Throughout the interview, emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Discuss your experience operating winding machines and maintaining quality standards

- Provide examples of how you have successfully resolved machine problems

- Quantify your achievements, such as reducing production defects or increasing machine efficiency

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position and company. Prepare questions that demonstrate your understanding of the role and industry.

- Inquire about the company’s growth plans and industry outlook

- Ask about opportunities for training and professional development

- Seek clarification on any aspects of the job or company culture that you are curious about

Next Step:

Now that you’re armed with the knowledge of Gasket Winder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Gasket Winder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini