Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gasoline Catalyst Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

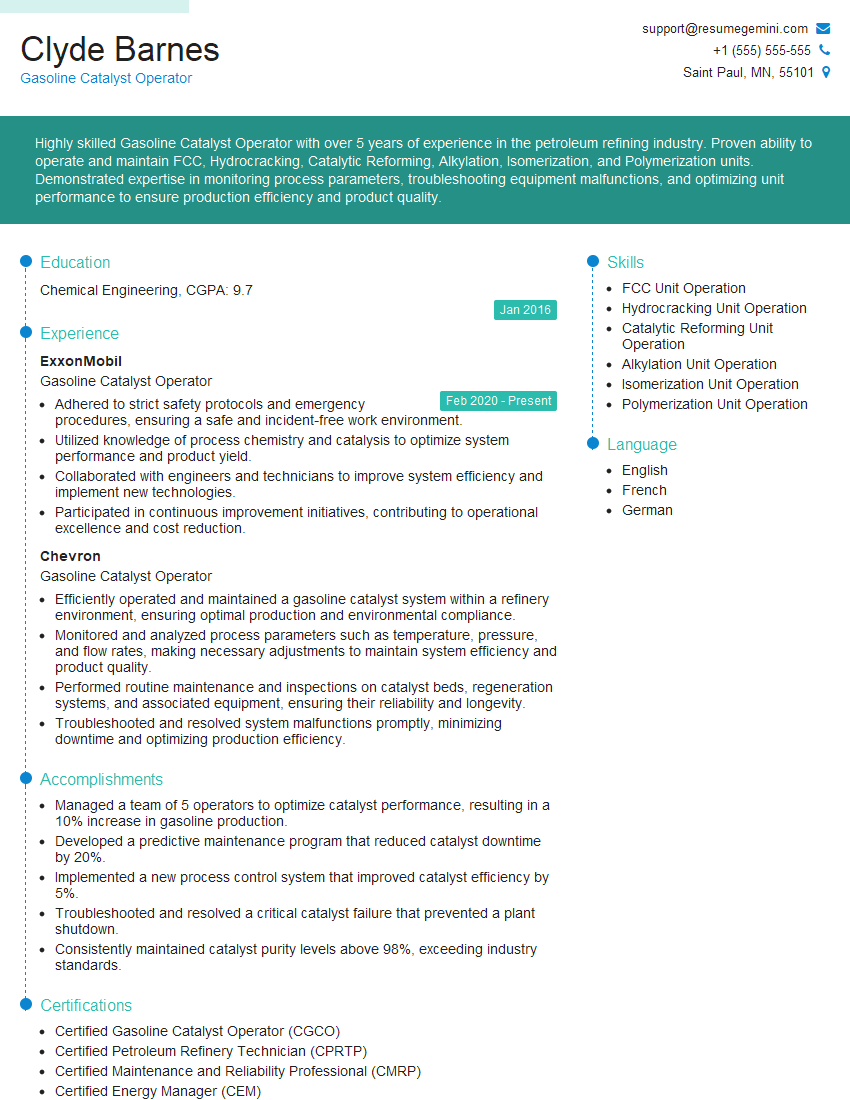

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gasoline Catalyst Operator

1. What are the key responsibilities of a Gasoline Catalyst Operator?

As a Gasoline Catalyst Operator, my primary responsibilities would include:

- Monitoring and adjusting the operation of gasoline catalyst units to ensure optimal performance

- Conducting routine maintenance and troubleshooting equipment to minimize downtime

- Analyzing data and making adjustments to operating parameters to optimize catalyst efficiency

- Collaborating with other operators and engineers to ensure smooth plant operations

- Maintaining a safe and clean work environment

2. Describe the different types of gasoline catalysts and their functions.

Types of Gasoline Catalysts

- Reforming Catalysts: Convert low-octane hydrocarbons into high-octane components

- Isomerization Catalysts: Rearrange the molecular structure of hydrocarbons to improve their performance

- Hydrotreating Catalysts: Remove impurities such as sulfur and nitrogen from gasoline

- Alkylation Catalysts: Combine olefins with isobutane to produce high-octane alkylates

Functions

- Increase octane rating

- Improve stability

- Reduce emissions

- Enhance fuel efficiency

3. Explain the role of temperature and pressure in gasoline catalyst operation.

Temperature and pressure play crucial roles in gasoline catalyst operation:

- Temperature: Affects the reaction rates and conversion efficiency of the catalyst. Higher temperatures generally increase reaction rates, but excessively high temperatures can deactivate the catalyst.

- Pressure: Influences the equilibrium of the reactions and the selectivity of the catalyst. Higher pressures shift the equilibrium towards the desired products.

4. What are the safety procedures for handling gasoline and catalyst materials?

Handling gasoline and catalyst materials requires strict adherence to safety procedures to prevent accidents and injuries:

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and respirators

- Avoid direct contact with gasoline and catalyst materials

- Handle gasoline in well-ventilated areas to prevent vapor build-up

- Store gasoline and catalyst materials in designated safe locations

- Follow established procedures for spills and emergencies

5. Describe the methods used to monitor and control the performance of gasoline catalysts.

Performance monitoring and control of gasoline catalysts involve:

- Analyzing feed and product streams: Monitoring the composition and properties of the feed and product streams, such as octane rating, sulfur content, and impurities

- Temperature and pressure monitoring: Continuously measuring and controlling the temperature and pressure of the catalyst bed

- Catalyst activity testing: Conducting periodic tests to determine the activity and selectivity of the catalyst

- Data analysis and adjustments: Analyzing data from monitoring devices and making adjustments to operating parameters to optimize catalyst performance

6. Explain the principles of catalytic reforming and how it is used in gasoline production.

Catalytic reforming is a process that converts low-octane hydrocarbons into high-octane components using a catalyst. It involves the following principles:

- Dehydrogenation: Removal of hydrogen atoms from hydrocarbon molecules

- Isomerization: Rearrangement of the carbon skeleton of hydrocarbon molecules

- Cyclization: Formation of aromatic rings in hydrocarbon molecules

In gasoline production, catalytic reforming is used to improve the octane rating and stability of gasoline.

7. What are the challenges and troubleshooting techniques in gasoline catalyst operation?

Challenges

- Catalyst deactivation (coking, poisoning, sintering)

- Pressure drop across the catalyst bed

- Temperature control and hot spots

- Feedstock variations

Troubleshooting Techniques

- Catalyst regeneration or replacement

- Cleaning the catalyst bed to reduce pressure drop

- Adjusting temperature and flow rates

- Adjusting feedstock composition

- Consulting with technical experts

8. Explain the importance of catalyst regeneration and how it is carried out in a gasoline catalyst unit.

Catalyst regeneration is crucial to maintain the activity and efficiency of gasoline catalysts. It involves removing impurities and contaminants that accumulate on the catalyst surface:

- Regeneration Process: The catalyst is subjected to high temperatures and/or steam to burn off coke and other deposits

- Frequency: Regeneration is performed periodically based on catalyst activity and feedstock conditions

- Importance: Regeneration restores the catalyst’s original activity, prevents deactivation, and extends its lifespan

9. What are the environmental regulations and best practices for gasoline catalyst operation?

Gasoline catalyst operations are subject to environmental regulations and best practices, including:

- Emission Control: Minimizing emissions of volatile organic compounds (VOCs), sulfur oxides (SOx), and nitrogen oxides (NOx)

- Waste Management: Proper disposal of spent catalyst and other waste materials

- Energy Efficiency: Optimizing process conditions to reduce energy consumption

- Safety Protocols: Adhering to safety regulations and implementing measures to prevent accidents and spills

10. Describe the career path and opportunities for advancement as a Gasoline Catalyst Operator.

The career path for a Gasoline Catalyst Operator typically includes:

- Junior Catalyst Operator: Entry-level position, performing routine tasks under supervision

- Gasoline Catalyst Operator: Responsible for operating and maintaining gasoline catalyst units independently

- Senior Gasoline Catalyst Operator: Advanced role, leading a team of operators and optimizing process performance

- Process Engineer: Designing and troubleshooting gasoline catalyst systems

- Plant Manager: Managing the overall operation of a gasoline refinery

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gasoline Catalyst Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gasoline Catalyst Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Gasoline Catalyst Operator, you will be responsible for the safe and efficient operation of gasoline catalyst units. Your key duties will include:

1. Process Monitoring and Control

You will be responsible for monitoring and controlling the refining process to ensure that gasoline meets quality specifications. This will involve:

- Monitoring process variables such as temperature, pressure, and flow rates

- Adjusting process parameters to maintain optimal operating conditions

2. Equipment Maintenance

You will be responsible for the maintenance and repair of gasoline catalyst units. This will involve:

- Inspecting equipment for wear and tear

- Performing routine maintenance tasks such as lubrication and cleaning

- Troubleshooting and repairing equipment breakdowns

3. Safety and Environmental Compliance

You will be responsible for ensuring that all safety and environmental regulations are followed. This will involve:

- Following established safety protocols

- Reporting any safety hazards or environmental concerns

- Adhering to all applicable environmental regulations

4. Data Analysis and Reporting

You will be responsible for collecting and analyzing data to ensure that gasoline catalyst units are operating efficiently. This will involve:

- Collecting data on process variables, equipment performance, and product quality

- Analyzing data to identify trends and areas for improvement

- Preparing reports on unit performance and recommending corrective actions

Interview Tips

To prepare for your interview for a Gasoline Catalyst Operator position, you should:

1. Research the company and the position

Take some time to learn about the company’s history, culture, and products. This will help you understand the company’s values and what they are looking for in a candidate. You should also research the specific position you are applying for to learn more about the job responsibilities and qualifications.

2. Prepare to talk about your experience and skills

Be prepared to discuss your experience operating gasoline catalyst units. Highlight your skills in process monitoring and control, equipment maintenance, safety and environmental compliance, and data analysis and reporting.

3. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice answering these questions in a clear and concise way.

4. Dress professionally and arrive on time

First impressions matter, so make sure to dress professionally for your interview. You should also arrive on time to show that you are respectful of the interviewer’s time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Gasoline Catalyst Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.