Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gauge and Weigh Machine Adjuster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

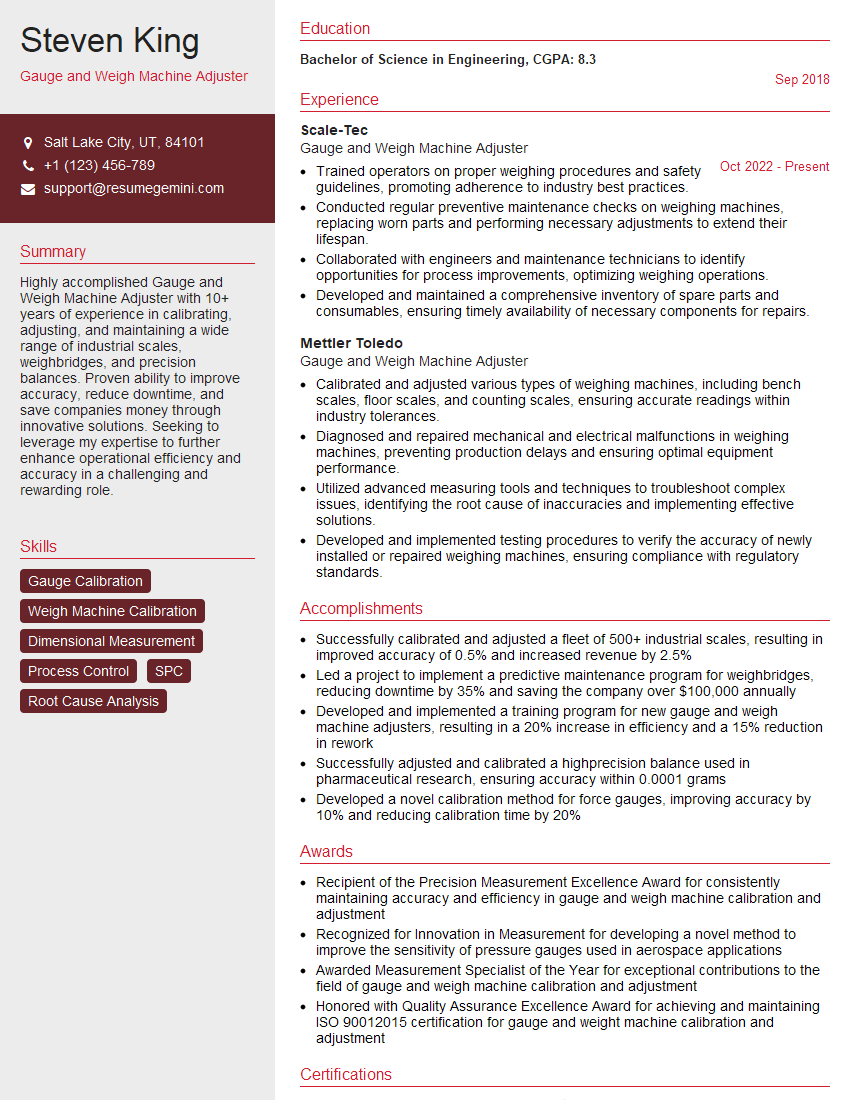

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gauge and Weigh Machine Adjuster

1. Describe the process you would follow to calibrate a weighing scale?

To calibrate a weighing scale, I would follow these steps:

- Ensure that the scale is clean and free of any debris.

- Place a known weight on the scale and check the reading.

- If the reading is not accurate, adjust the scale’s calibration settings accordingly.

- Repeat steps 2 and 3 until the scale accurately measures the known weight.

- Once the scale is calibrated, verify its accuracy by weighing several different objects.

2. What are the different types of weighing scales, and what are their applications?

Mechanical scales:

- Mechanical scales use a beam and weights to measure weight.

- They are typically used in low-capacity applications, such as weighing food or postage.

Electronic scales:

- Electronic scales use load cells to measure weight.

- They are typically more accurate and precise than mechanical scales and can be used in a wider range of applications.

Analytical balances:

- Analytical balances are highly sensitive electronic scales used to measure very small weights.

- They are typically used in laboratories and research settings.

3. What are some common problems that can occur with weighing scales, and how would you troubleshoot them?

Some common problems that can occur with weighing scales include:

- Inaccurate readings: This can be caused by a variety of factors, such as a faulty load cell, incorrect calibration, or environmental factors.

- Drifting readings: This can be caused by a problem with the scale’s electronics or by environmental factors.

- Zero point error: This can be caused by a problem with the scale’s zero point adjustment.

To troubleshoot these problems, I would first check the scale’s calibration and make sure that it is clean and free of any debris. If the problem persists, I would then check the scale’s electronics and look for any loose connections or damaged components.

4. What are the safety precautions that should be taken when using weighing scales?

When using weighing scales, it is important to take the following safety precautions:

- Do not overload the scale.

- Do not place hot objects on the scale.

- Do not use the scale in a wet or dusty environment.

- If the scale is damaged, do not use it.

5. What are your qualifications and experience in the field of weighing scale adjustment?

I have been working as a weighing scale adjuster for the past 5 years. In this role, I have been responsible for the calibration, maintenance, and repair of a wide range of weighing scales, including mechanical scales, electronic scales, and analytical balances.

I have a strong understanding of the principles of weighing and measurement, and I am proficient in the use of a variety of test equipment and calibration procedures.

6. What are your strengths and weaknesses as a weighing scale adjuster?

My strengths as a weighing scale adjuster include:

- Strong technical skills and a deep understanding of the principles of weighing and measurement.

- Experience in the calibration, maintenance, and repair of a wide range of weighing scales.

- Excellent problem-solving skills and a strong attention to detail.

- Ability to work independently and as part of a team.

My weaknesses as a weighing scale adjuster include:

- I am relatively new to the field, and I am still learning about some of the more complex aspects of weighing scale adjustment.

- I am not yet certified as a weighing scale adjuster, but I am in the process of obtaining my certification.

7. What are your career goals?

My career goal is to become a certified weighing scale adjuster and to continue to develop my skills and knowledge in the field of weighing and measurement.

I am also interested in learning more about the use of weighing scales in different industries, such as manufacturing, healthcare, and retail.

8. Why are you interested in working for our company?

I am interested in working for your company because of your reputation as a leading provider of weighing scales and weighing solutions.

I am confident that I can use my skills and experience to make a significant contribution to your company and help you to continue to grow and succeed.

9. What are your salary expectations?

My salary expectations are in line with the industry average for a weighing scale adjuster with my experience and qualifications.

I am willing to negotiate my salary based on the benefits package and the company’s culture and values.

10. Do you have any questions for me?

I do have a few questions for you:

- What are the company’s core values?

- What is the company’s culture like?

- What are the company’s growth plans for the future?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gauge and Weigh Machine Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gauge and Weigh Machine Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The key responsibilities of a Gauge and Weigh Machine Adjuster include:

1. Installation and Repair of Measuring Equipment

– Installing and maintaining precision gauges, scales, and other weighing equipment

– Calibrating and adjusting measuring equipment to ensure accuracy and precision

– Repairing and replacing defective components to maintain equipment functionality

2. Quality Control and Assurance

– Performing quality control checks on products and materials to ensure they meet specifications

– Monitoring production processes and identifying areas for improvement in accuracy and efficiency

– Maintaining records of inspections and calibrations for compliance and traceability

3. Troubleshooting and Problem-Solving

– Identifying and resolving technical issues related to measuring equipment

– Analyzing data from equipment and diagnosing potential problems

– Implementing corrective actions and recommendations to improve equipment performance

4. Collaboration and Communication

– Working closely with engineers, technicians, and production teams to provide support and expertise

– Communicating technical information and providing training on proper equipment use

– Maintaining a strong understanding of industry standards and best practices

Interview Preparation Tips

1. Research the Company and Position

– Thoroughly review the company’s website, LinkedIn page, and any available job description

– Identify the company’s mission, values, and industry position

– Understand the specific requirements and responsibilities of the Gauge and Weigh Machine Adjuster role

2. Practice Your Technical Skills

– Review concepts related to precision measurements, calibration, and quality control

– Practice troubleshooting common problems and describing your approach to problem-solving

– Consider preparing examples of past projects or experiences that showcase your technical abilities

3. Emphasize Your Attention to Detail

– Highlight your strong attention to detail and accuracy in your resume and during the interview

– Provide specific examples of how you have ensured precision in your previous roles

– Explain how you maintain a meticulous approach to your work and minimize errors

4. Show Your Commitment to Learning

– Express your eagerness to stay updated with industry standards and best practices

– Mention any certifications or training programs you have completed or are pursuing

– Show that you are proactive in seeking knowledge and improving your skills

5. Be Confident and Enthusiastic

– Demonstrate your confidence in your abilities and your enthusiasm for the position

– Share examples of how you have overcome challenges and contributed to previous teams

– Show that you are eager to make a positive impact within the organization

Next Step:

Now that you’re armed with the knowledge of Gauge and Weigh Machine Adjuster interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Gauge and Weigh Machine Adjuster positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini