Are you gearing up for a career in Gauger? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Gauger and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

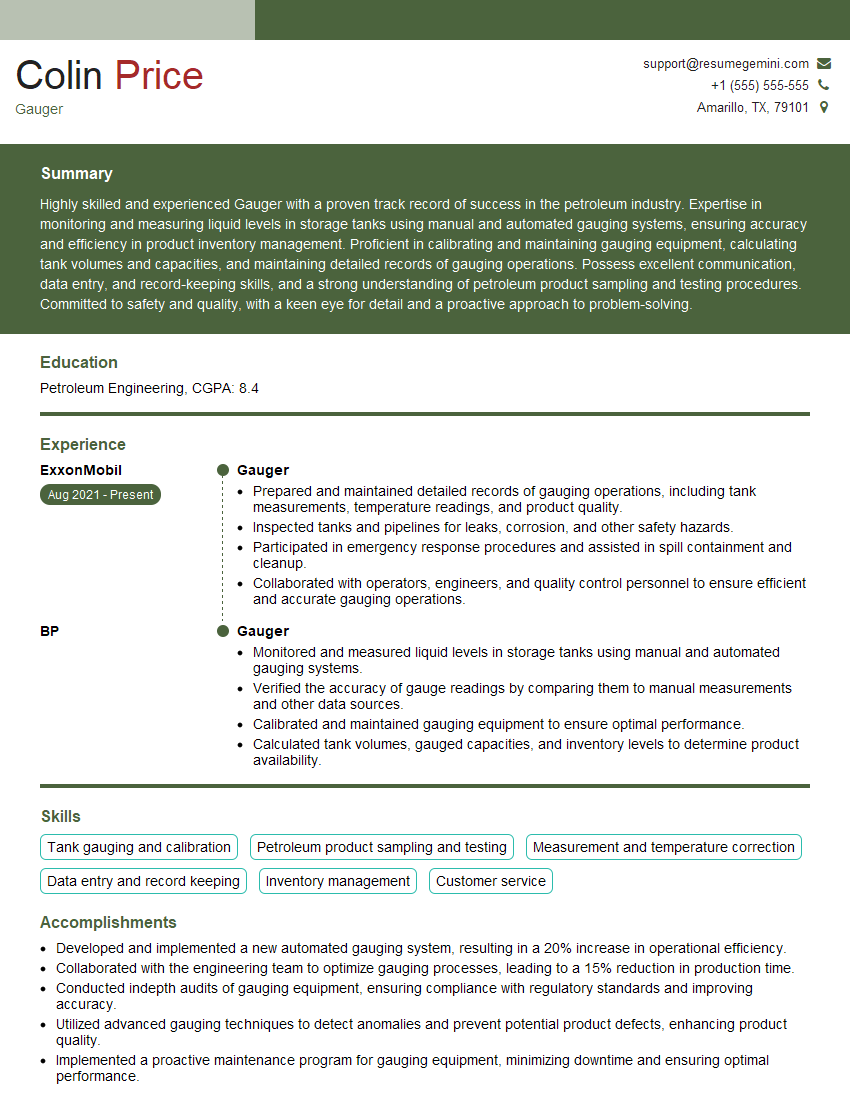

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gauger

1. What are the key responsibilities of a Gauger?

As a Gauger, my key responsibilities typically include:

- Measuring and determining the volume, weight, and quality of petroleum products and other liquids

- Taking samples for laboratory testing to ensure product quality

- Calibrating and maintaining gauging equipment, such as tanks, scales, and flow meters

- Recording and reporting measurements and test results accurately

- Monitoring inventory levels and ensuring compliance with regulations and safety standards

2. What are the different methods used for gauging petroleum products?

Manual Gauging

- Using a calibrated dipstick or tape to measure the depth of the liquid

- Calculating the volume based on tank dimensions and the measured depth

Automatic Tank Gauging (ATG) Systems

- Employing sensors and transmitters to continuously monitor tank levels and temperature

- Provides real-time data and generates reports on inventory levels, usage, and alarms

Ultrasonic Gauging

- Using ultrasonic waves to measure the distance between the sensor and the liquid surface

- Provides accurate and non-invasive measurements, suitable for hazardous environments

3. What are the factors that can affect the accuracy of gauging measurements?

- Tank geometry and calibration

- Temperature variations

- Product properties, such as density and viscosity

- Equipment precision and maintenance

- Human error and bias

4. How do you ensure the accuracy and reliability of gauging data?

- Regular calibration and maintenance of gauging equipment

- Following standardized gauging procedures and protocols

- Performing quality control checks and cross-verifying measurements

- Training and certification of gaugers

- Using automated systems with redundancy and error detection capabilities

5. What are the safety precautions that should be taken when gauging petroleum products?

- Wearing appropriate personal protective equipment (PPE), including gloves, safety glasses, and respiratory protection

- Ensuring proper ventilation and avoiding confined spaces

- Handling flammable products with care and following fire safety protocols

- Being aware of potential hazards, such as spills, leaks, and vapors

- Following emergency response procedures in case of an incident

6. What are the different types of sampling techniques used in gauging?

- Manual Sampling: Using a thief sampler or dipper to extract a sample directly from the tank

- Automatic Sampling: Employing automated samplers to collect samples at predetermined intervals

- Composite Sampling: Combining multiple samples taken over a period to obtain an average representation

- Grab Sampling: Taking a single sample at a specific point in time

7. How do you handle and store samples to maintain their integrity?

- Using clean and sterile containers

- Properly labeling samples with relevant information

- Storing samples in a controlled environment to prevent degradation

- Following chain-of-custody protocols to ensure sample traceability

- Disposing of samples safely and responsibly

8. What are the different types of tests performed on petroleum samples?

- Density and API Gravity: Determining the mass per unit volume and specific gravity

- Water Content: Measuring the amount of water present in the sample

- Sediment and Haze: Assessing the presence of solid particles and cloudiness

- Distillation Tests: Analyzing the boiling range and composition of the sample

- Flash Point: Determining the temperature at which the sample ignites

9. How do you interpret the results of laboratory tests and apply them to gauging operations?

- Density and API Gravity: Used to calculate the volume and mass of the product

- Water Content: Adjusted for accurate volume measurements and to prevent contamination

- Sediment and Haze: Investigated to determine potential quality issues

- Distillation Tests: Used to assess product quality and identify specific components

- Flash Point: Considered for safety purposes and handling procedures

10. What are the regulations and standards that govern gauging practices?

- ASTM International Standards: D1085 (Standard Test Method for Gaging Petroleum and Petroleum Products), D4057 (Standard Practice for Manual Sampling of Petroleum and Petroleum Products)

- API Standards: MPMS Chapter 11.1 (Standard Practice for Measurement of Petroleum Liquids by Manual Tank Gaging), Chapter 11.2 (Standard Practice for Automatic Tank Gaging)

- Environmental Protection Agency (EPA) Regulations: 40 CFR Part 63 Subpart R (National Emission Standards for Gasoline Distribution Facilities)

- Occupational Safety and Health Administration (OSHA) Regulations: 29 CFR 1910.106 (Flammable and Combustible Liquids)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gauger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gauger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gaugers play a crucial role in the oil and gas industry, ensuring accurate measurement and monitoring of petroleum products. Their key job responsibilities include:

1. Measurement and Sampling

Gaugers use specialized equipment to accurately measure the volume and density of petroleum products stored in tanks and pipelines.

2. Quality Control

They collect and test samples to ensure the quality of petroleum products meets industry standards and customer specifications.

3. Inventory Management

Gaugers maintain detailed records of product levels, ensuring accurate inventory tracking and forecasting.

4. Calibration and Maintenance

They calibrate and maintain measurement equipment to ensure accurate readings and compliance with industry regulations.

5. Safety and Compliance

Gaugers adhere to strict safety protocols and ensure compliance with environmental regulations related to petroleum handling.

Interview Tips

Preparing thoroughly for a gauger interview is essential. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s operations, the oil and gas industry, and current trends.

2. Highlight Relevant Skills and Experience

Emphasize your expertise in measurement techniques, quality control procedures, and inventory management. Share specific examples to showcase your abilities.

3. Prepare for Technical Questions

Be prepared to answer questions about gauging equipment, sampling techniques, and quality control standards. Practice explaining these concepts clearly and concisely.

4. Show Safety Consciousness

подчеркнуть your understanding of industry safety protocols and your commitment to maintaining a safe work environment.

5. Prepare Questions for the Interviewer

Asking thoughtful questions demonstrates your interest and engagement. Prepare questions about the company’s operations, growth plans, or industry challenges.

6. Dress Professionally and Arrive Punctually

Make a positive first impression by dressing professionally and arriving for the interview on time. This shows respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gauger interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!