Feeling lost in a sea of interview questions? Landed that dream interview for Gear Cutter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Gear Cutter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

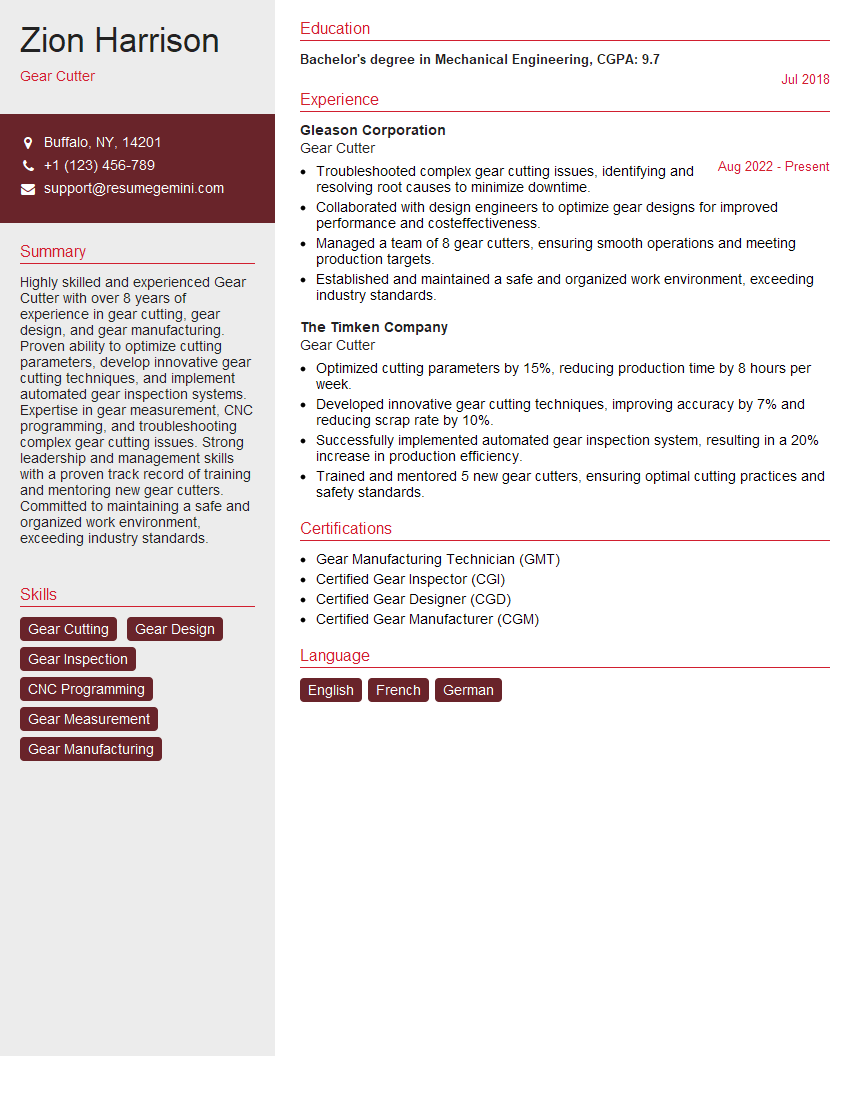

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Cutter

1. Explain the process of gear cutting?

- Gear cutting is a machining process that creates gears.

- The process begins with a blank, which is a piece of metal that has been cut to the desired shape and size.

- The blank is then mounted on a machine and a cutting tool is used to remove material from the blank, creating the gear teeth.

2. What are the different types of gear cutting machines?

CNC Gear Cutting Machine

- CNC gear cutting machines are computer-controlled machines that use a cutting tool to remove material from the blank.

- CNC machines are very precise and can produce gears with very complex tooth profiles.

Hobbing Machine

- Hobbing machines use a hob, which is a cutting tool with helical teeth, to cut gears.

- Hobbing machines are very fast and can produce gears with a wide range of tooth profiles.

Shaping Machine

- Shaping machines use a shaping cutter, which is a cutting tool with a single tooth, to cut gears.

- Shaping machines are very precise and can produce gears with very complex tooth profiles.

3. What are the different types of gear materials?

- Gears can be made from a variety of materials, including steel, stainless steel, aluminum, and plastic.

- The type of material used will depend on the application.

- For example, steel gears are strong and durable, while plastic gears are lightweight and corrosion-resistant.

4. What are the different types of gear tooth profiles?

- There are many different types of gear tooth profiles, including involute, cycloidal, and helical.

- The type of tooth profile used will depend on the application.

- For example, involute gears are the most common type of gear and are used in a wide range of applications.

5. What are the different types of gear manufacturing processes?

- There are many different types of gear manufacturing processes, including casting, forging, and machining.

- The type of manufacturing process used will depend on the type of gear being produced.

- For example, casting is a good option for producing large gears, while machining is a good option for producing small gears.

6. What are the different types of gear quality standards?

- There are many different types of gear quality standards, including AGMA, DIN, and ISO.

- The type of quality standard used will depend on the application.

- For example, AGMA standards are commonly used in the United States, while DIN standards are commonly used in Europe.

7. What are the different types of gear inspection methods?

- There are many different types of gear inspection methods, including visual inspection, dimensional inspection, and functional inspection.

- The type of inspection method used will depend on the type of gear being inspected.

- For example, visual inspection is a good option for checking for surface defects, while dimensional inspection is a good option for checking for dimensional accuracy.

8. What are the different types of gear lubrication methods?

- There are many different types of gear lubrication methods, including splash lubrication, oil bath lubrication, and grease lubrication.

- The type of lubrication method used will depend on the type of gear being lubricated.

- For example, splash lubrication is a good option for gears that are running at low speeds, while oil bath lubrication is a good option for gears that are running at high speeds.

9. What are the different types of gear failure modes?

- There are many different types of gear failure modes, including tooth breakage, pitting, and scoring.

- The type of failure mode will depend on the type of gear and the application.

- For example, tooth breakage is a common failure mode for gears that are subjected to high loads, while pitting is a common failure mode for gears that are subjected to high speeds.

10. What are the different types of gear repair methods?

- There are many different types of gear repair methods, including welding, grinding, and machining.

- The type of repair method used will depend on the type of gear and the type of damage.

- For example, welding is a good option for repairing broken teeth, while grinding is a good option for repairing pitted or scored gears.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gear Cutters play a crucial role in manufacturing processes involving the production of precision gears and components. Their responsibilities encompass:

1. Gear Cutting and Finishing

Using advanced gear cutting machines, Gear Cutters operate and maintain equipment to cut gears precisely according to specifications. They perform hobbing, shaping, and shaving operations to create high-quality gears.

2. Quality Control and Inspection

Gear Cutters conduct thorough inspections and quality checks to ensure that gears meet stringent standards and tolerances. They use specialized measuring instruments and gauges to verify dimensions, surface finishes, and tooth profiles.

3. Setup and Maintenance

They are responsible for setting up and maintaining gear cutting machines, ensuring optimal performance and efficiency. They perform regular maintenance, calibration, and repairs to maximize machine uptime.

4. Material Handling and Storage

Gear Cutters handle and store raw materials and finished products safely and efficiently. They follow proper procedures for receiving, storing, and transporting gears to avoid damage or loss.

Interview Tips

Preparing meticulously for a Gear Cutter interview is essential. Here are a few tips and tricks to help you ace it:

1. Research the Company and Industry

Research the company’s background, products, and industry. This shows the interviewer that you’re genuinely interested in the role and the organization. It also helps you tailor your answers to the company’s specific needs.

2. Highlight Relevant Experience and Skills

Review the job description carefully and ensure that your resume and interview responses emphasize your relevant experience and skills. Quantify your accomplishments with specific examples to demonstrate your capabilities.

3. Understand Gear Manufacturing Processes

Be well-versed in gear manufacturing processes, including different cutting techniques, equipment, and quality control procedures. This demonstrates your technical knowledge and understanding of the industry.

4. Prepare for Common Interview Questions

Anticipate common interview questions related to your experience, skills, and understanding of gear cutting. Practice your answers thoughtfully and provide concrete examples to support your claims.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gear Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!