Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gear Cutting Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

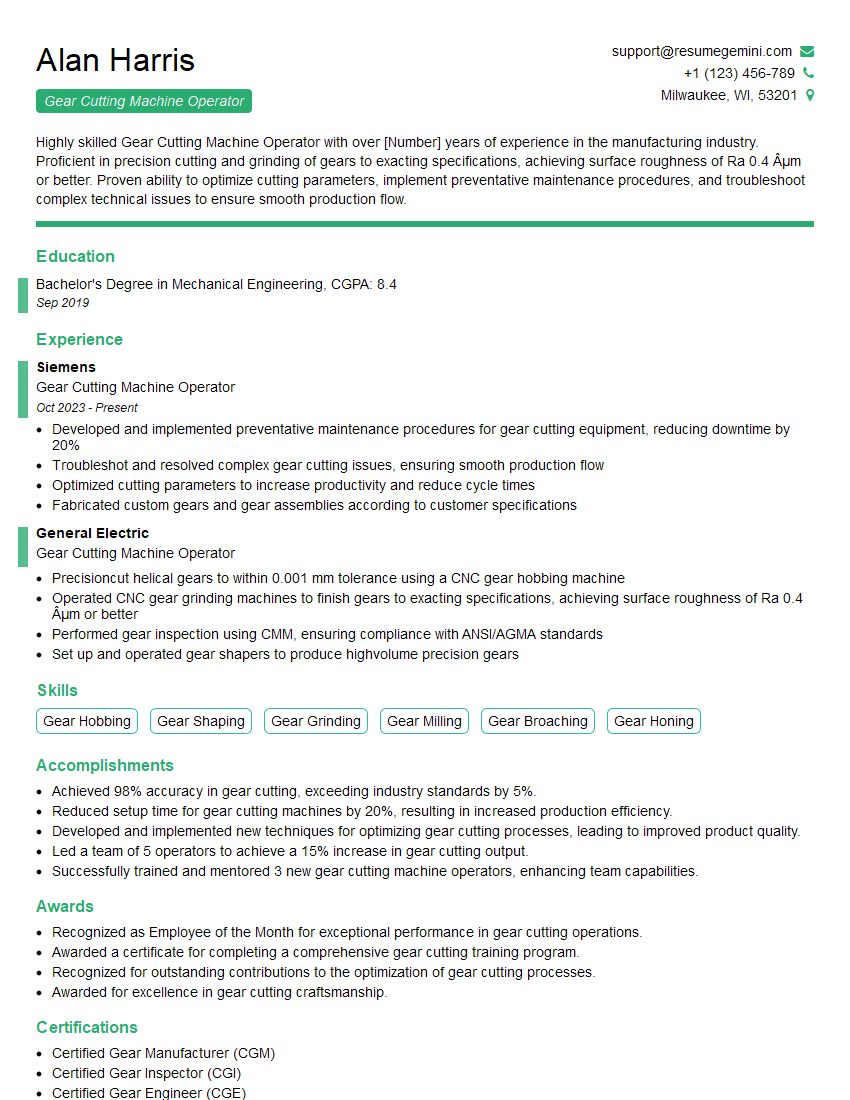

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Cutting Machine Operator

1. Explain the process of gear cutting, from start to finish?

The gear cutting process involves several steps:

- Setup: The gear blank is mounted on the machine, and the appropriate cutting tool is selected.

- Roughing: The cutting tool removes excess material from the blank, creating the basic shape of the gear.

- Finishing: The cutting tool refines the shape of the gear, creating the desired profile and tooth spacing.

- Deburring: Any sharp edges or burrs are removed from the gear to ensure smooth operation.

- Inspection: The finished gear is inspected to ensure it meets the required specifications.

2. What are the different types of gear cutting machines?

There are several types of gear cutting machines, including:

Gear Hobbing Machines

- Use a rotating hob cutter to cut the gear teeth.

- Suitable for high-volume production of spur and helical gears.

Gear Shaping Machines

- Use a reciprocating cutting tool to shape the gear teeth.

- Used for cutting internal and external gears, as well as non-standard gear profiles.

Gear Milling Machines

- Use a rotating milling cutter to cut the gear teeth.

- Flexible and versatile, can cut a wide range of gear types.

3. What are the key factors to consider when selecting a gear cutting tool?

When selecting a gear cutting tool, several factors should be considered:

- Material: The tool material should be harder than the gear blank material to ensure durability.

- Geometry: The tool geometry should be appropriate for the gear profile being cut.

- Size: The tool size should be proportional to the gear size.

- Coating: Tool coatings can improve tool life and performance.

4. What are the potential causes of gear cutting errors?

- Tool wear: Worn tools can result in inaccurate gear profiles.

- Machine misalignment: Improper machine setup can lead to errors in gear positioning.

- Material defects: Inclusions or other defects in the gear blank can affect the cutting process.

5. How do you ensure the accuracy of gear cutting operations?

- Regular tool inspection and maintenance: Worn or damaged tools should be replaced.

- Proper machine calibration: Machines should be regularly checked for accuracy.

- Use of precision measuring tools: Gear dimensions should be carefully measured to ensure accuracy.

- Quality control procedures: Inspecting finished gears to verify compliance with specifications.

6. What are the safety precautions that should be taken when operating a gear cutting machine?

- Wear appropriate safety gear: Eye protection, gloves, and hearing protection.

- Keep work area clean and organized: Prevent slips and falls.

- Secure the gear blank properly: Ensure it is firmly held to prevent movement during cutting.

- Follow proper machine operation procedures: Avoid overloading or mishandling the machine.

7. What are some of the common challenges faced by gear cutting machine operators?

- Achieving precise gear dimensions: Requires skilled operation and proper machine calibration.

- Tool wear and breakage: Regular tool maintenance is essential.

- Minimizing noise and vibration: Proper machine setup and maintenance can reduce these issues.

8. What are the emerging trends in gear cutting technology?

- Advanced cutting tools: New materials and coatings improve tool life and performance.

- Automated gear cutting machines: Reduce setup time and increase efficiency.

- 3D printing: Enables the production of complex gear shapes and prototypes.

9. How do you stay updated with the latest advancements in gear cutting techniques?

- Attend industry conferences and workshops: Learn about new technologies and best practices.

- Read technical journals and articles: Stay informed about industry developments.

- Engage with suppliers and manufacturers: Seek information on new products and innovations.

10. Describe a situation where you encountered a problem with a gear cutting machine and how you resolved it.

Once, during a gear cutting operation, I noticed excessive vibration. I immediately stopped the machine and checked the setup. I discovered that the gear blank was not properly secured, causing it to move during cutting. I re-secured the gear blank and restarted the operation, which resolved the vibration issue and ensured accurate gear cutting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Cutting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Cutting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gear Cutting Machine Operators are responsible for setting up, operating, and maintaining gear cutting machines. They work with a variety of materials, including metals, plastics, and ceramics, to create gears for a wide range of industries.

1. Set Up and Operate Gear Cutting Machines

Operators must be able to set up and operate gear cutting machines according to specifications. This includes loading the machine with the correct cutting tools, setting the cutting speed and feed rate, and aligning the workpiece.

- Load the machine with the correct cutting tools.

- Set the cutting speed and feed rate.

- Align the workpiece.

2. Monitor the Cutting Process

Operators must monitor the cutting process to ensure that the gears are being cut to the correct specifications. They must also be able to troubleshoot any problems that may occur during the cutting process.

- Monitor the cutting process to ensure that the gears are being cut to the correct specifications.

- Troubleshoot any problems that may occur during the cutting process.

3. Inspect and Measure Gears

Operators must inspect and measure the gears to ensure that they meet the required specifications. They must also be able to identify and correct any defects.

- Inspect and measure the gears to ensure that they meet the required specifications.

- Identify and correct any defects.

4. Maintain Gear Cutting Machines

Operators are responsible for maintaining gear cutting machines to ensure that they are in good working order. This includes cleaning, lubricating, and adjusting the machines.

- Clean the machines.

- Lubricate the machines.

- Adjust the machines.

Interview Tips

Preparing for an interview for a Gear Cutting Machine Operator position requires a combination of technical knowledge and an understanding of the industry. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Before you go to your interview, be sure to research the company and the position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website to learn more about their history, products, and services.

- Read industry publications and news articles to stay up-to-date on the latest trends in the gear cutting industry.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare an elevator pitch that highlights your skills and experience as a Gear Cutting Machine Operator.

- Be prepared to discuss your knowledge of the gear cutting process, including the different types of gears, cutting tools, and machines used.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience as a Gear Cutting Machine Operator. Be prepared to discuss your responsibilities, accomplishments, and any challenges you have faced.

- Quantify your accomplishments whenever possible. For example, instead of saying “I operated a gear cutting machine,” you could say “I operated a gear cutting machine and increased production by 10%.”

- Be prepared to discuss your experience with different types of gear cutting machines and materials.

4. Ask Questions

Asking questions at the end of an interview shows that you are interested in the position and the company. It is also a good way to learn more about the company and the position.

- Ask about the company’s culture and values.

- Ask about the company’s plans for the future.

Next Step:

Now that you’re armed with the knowledge of Gear Cutting Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Gear Cutting Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini