Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gear Finisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

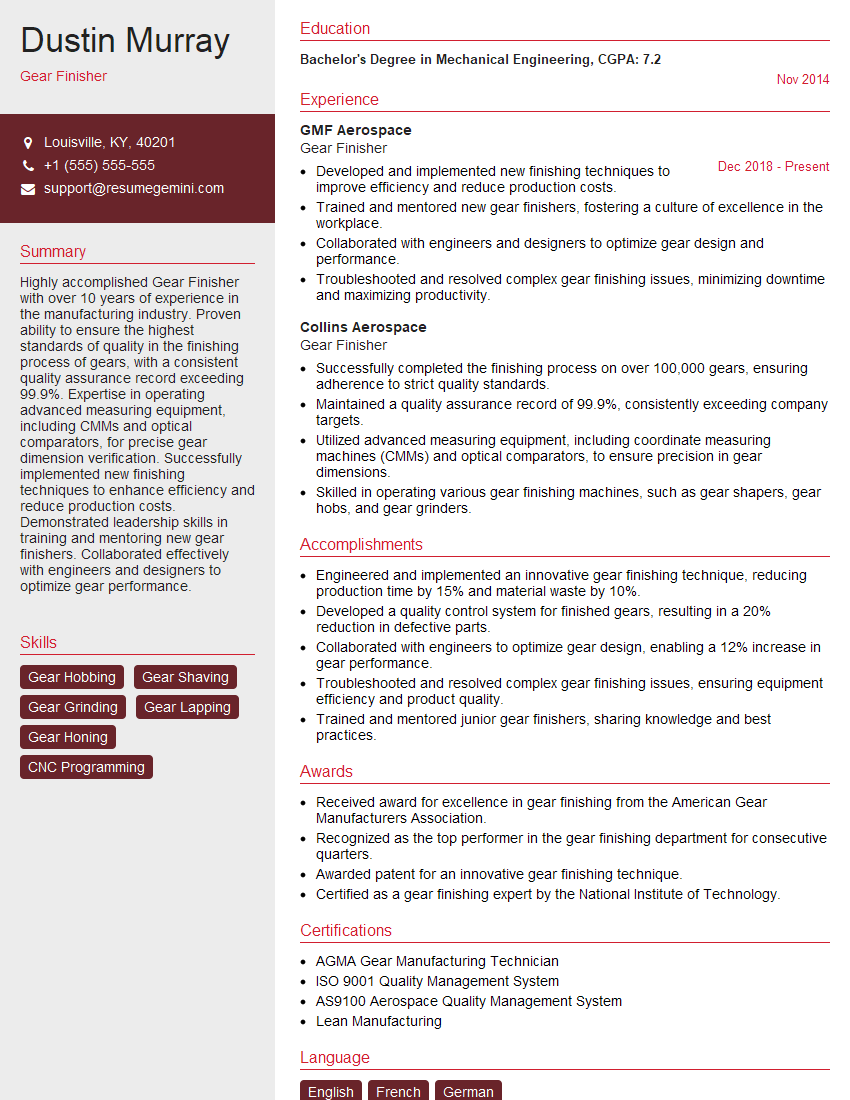

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Finisher

1. What is the role of a gear finisher?

As a gear finisher, my primary responsibility is to ensure the precision and quality of finished gears. This involves performing various finishing processes, such as grinding, honing, and lapping, to achieve the desired specifications and tolerances.

2. Can you explain the different types of gear finishing processes?

Grinding

- Removes excess material and shapes the teeth

- Uses abrasive wheels to create a smooth surface finish

Honing

- Refines the surface finish of the teeth

- Uses abrasive stones to remove microscopic imperfections

Lapping

- Improves the accuracy and precision of the gear teeth

- Uses a fine abrasive compound to remove any remaining burrs or imperfections

3. What are the key factors to consider when selecting a gear finishing process?

When selecting a gear finishing process, I consider several factors, including:

- The type of gear material

- The desired surface finish

- The required accuracy and precision

- The production volume and cost

4. How do you ensure the quality of finished gears?

I follow a rigorous quality control process to ensure the quality of finished gears. This includes:

- Inspecting incoming gears for defects

- Monitoring the finishing processes to maintain consistency

- Performing final inspections to verify that the gears meet specifications

- Implementing corrective actions to address any quality issues

5. What are the common challenges you face as a gear finisher?

Some common challenges I face as a gear finisher include:

- Achieving the required surface finish and accuracy

- Minimizing production time while maintaining quality

- Working with different types of gear materials and designs

- Staying up-to-date with the latest finishing technologies

6. How do you stay informed about the latest advancements in gear finishing?

To stay informed about the latest advancements in gear finishing, I:

- Attend industry conferences and workshops

- Read technical journals and articles

- Network with other gear finishing professionals

- Participate in training programs

7. Can you explain the importance of gear tooth profile accuracy?

Accurate gear tooth profiles are crucial for several reasons:

- They ensure smooth and efficient gear meshing

- They reduce noise and vibration

- They improve power transmission efficiency

- They extend the life of gears and other drivetrain components

8. What types of gear measurement equipment do you use?

I use a variety of gear measurement equipment, including:

- Gear measuring machines

- Coordinate measuring machines (CMMs)

- Optical comparators

- Surface roughness testers

9. How do you interpret gear measurement data?

I interpret gear measurement data by comparing it to industry standards and specifications. This allows me to assess the accuracy and quality of the finished gears and identify any potential issues.

10. What is your approach to continuous improvement in gear finishing?

I believe in continuous improvement and regularly evaluate my processes and procedures to identify areas for enhancement. I also seek feedback from colleagues and customers to gain different perspectives and stay abreast of best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gear Finishers are skilled machinists who specialize in the final finishing operations on gears. They work in a variety of industries, including automotive, aerospace, and manufacturing.

1. Gear Inspection

Inspect gears for dimensional accuracy, surface finish, and other quality standards using precision measuring instruments.

- Use calipers, micrometers, and other tools to measure gear dimensions.

- Check gear tooth profiles for accuracy using optical comparators.

2. Gear Grinding

Operate grinding machines to remove excess material from gears and achieve desired tolerances.

- Set up and operate CNC grinding machines.

- Monitor grinding process to ensure precision and efficiency.

3. Gear Lapping

Use lapping machines to smooth and polish gear surfaces.

- Select appropriate abrasive compounds and lapping tools.

- Monitor lapping process to achieve desired surface finish.

4. Gear Hobbing

Operate hobbing machines to cut gear teeth.

- Set up and adjust hobbing machines.

- Monitor hobbing process to ensure accuracy and quality.

Interview Tips

Preparing thoroughly is crucial before any job interview. Here are some tips to help you ace your interview for a gear finisher position.

1. Research the Company and Job

Familiarize yourself with the company’s website, industry, and the specific job responsibilities. This demonstrates your interest and enthusiasm.

- Note down relevant keywords and phrases from the job description to incorporate into your answers.

2. Highlight Relevant Experience and Skills

Emphasize your experience in gear inspection, grinding, lapping, or hobbing. Quantify your accomplishments and provide specific examples.

- Example: “In my previous role, I was responsible for inspecting over 500 gears per day, ensuring they met precise dimensional and surface finish specifications.”

3. Technical Knowledge and Proficiency

Demonstrate your understanding of gear manufacturing processes, including grinding techniques, lapping techniques, and hobbing principles.

- Be prepared to discuss different types of gear inspection equipment and their applications.

4. Teamwork and Attention to Detail

Gear finishing often involves working in a team environment and adhering to strict quality standards. Highlight your ability to work collaboratively and your attention to detail.

- Example: “In my previous team, I assisted in developing a new inspection process that reduced inspection time by 20% while maintaining high quality standards.”

5. Ask Questions

Asking insightful questions shows that you are engaged and interested. It also gives you an opportunity to clarify any job-related details.

- Example: “Can you provide more information about the company’s quality control procedures?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gear Finisher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.