Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gear Generator Set Up Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

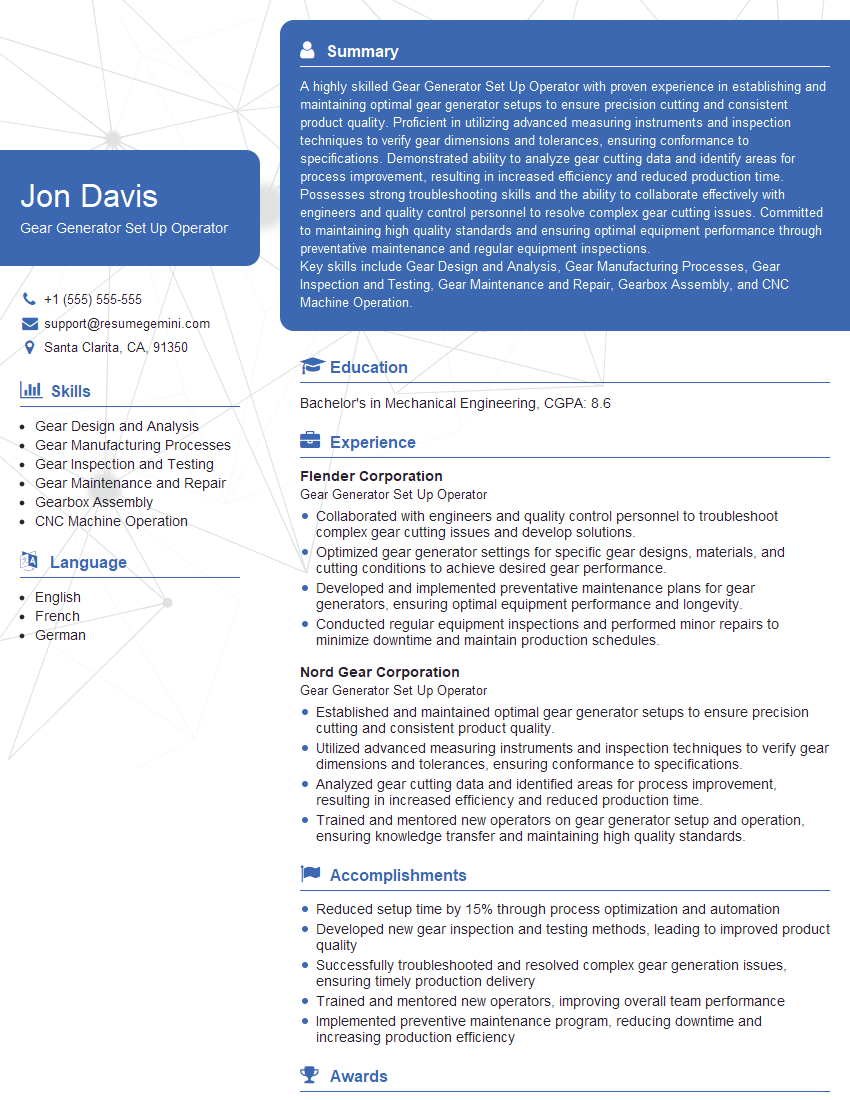

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Generator Set Up Operator

1. Explain the process of setting up a gear generator for gear cutting?

- Align the workpiece with the chuck and spindle.

- Mount the appropriate cutting tool.

- Set the cutting speed and feed rate.

- Start the gear generator and monitor the cutting process.

- Make adjustments to the cutting parameters as needed.

2. What are the different types of gear generators and their applications?

- Hobbing machines are used to cut external gears.

- Shaping machines are used to cut internal gears.

- Grinding machines are used to finish gears.

3. How do you ensure that the gears cut on the gear generator meet the required specifications?

- Use the correct cutting tools and parameters.

- Calibrate the gear generator regularly.

- Inspect the gears after cutting.

- Make adjustments to the cutting process as needed.

4. What are the common troubleshooting techniques for gear generator problems?

- Chatter can be caused by incorrect cutting parameters, worn cutting tools, or misalignment of the workpiece.

- Gear tooth breakage can be caused by incorrect cutting parameters, worn cutting tools, or excessive stress on the gear.

- Runout can be caused by misalignment of the workpiece or the cutting tool.

5. What are the key safety considerations when operating a gear generator?

- Wear appropriate safety gear.

- Keep the work area clean and free of debris.

- Never reach into the cutting area while the machine is running.

- Follow all manufacturer’s instructions.

6. What are the preventive maintenance tasks that need to be performed on a gear generator?

- Lubricate the machine according to the manufacturer’s instructions.

- Clean the machine regularly.

- Inspect the cutting tools regularly and replace them when necessary.

- Calibrate the machine regularly.

- Keep a maintenance log.

7. What are the different types of gear cutting fluids and their applications?

- Mineral oils are general-purpose cutting fluids.

- Synthetic oils are more expensive than mineral oils but offer better performance.

- Water-soluble oils are environmentally friendly but can cause rust.

- Straight oils are not soluble in water and are used for heavy-duty cutting.

8. What are the benefits of using CNC gear generators?

- Increased accuracy

- Faster cutting times

- Reduced labor costs

- Improved safety

9. What are the future trends in gear cutting technology?

- Increased use of automation

- Development of new cutting tools and materials

- Improved software for gear design

10. What are your strengths and weaknesses as a Gear Generator Set Up Operator?

- Strengths: I am a highly skilled and experienced Gear Generator Set Up Operator with a proven track record of success.

- Weaknesses: I am sometimes too detail-oriented, which can slow me down.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Generator Set Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Generator Set Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Gear Generator Set Up Operator is responsible for setting up and maintaining gear generating machines. They work closely with engineers and other technicians to ensure that the machines are operating correctly and producing high-quality gears. Key responsibilities include:

1. Machine Setup and Maintenance

Setting up and operating gear generating machines, following engineering drawings and specifications, to produce gears with the required dimensions and tolerances

- Installing and adjusting cutting tools, such as hobs and cutters

- Setting up and calibrating the machine’s parameters, such as speed, feed, and depth of cut

- Monitoring the machine’s operation and making adjustments as needed to maintain optimal performance

- Performing preventive maintenance on the machine, such as lubrication and cleaning

2. Quality Control

Inspecting gears to ensure they meet the required specifications. This may involve using measuring tools, such as calipers and micrometers, and checking the gears for defects, such as burrs and cracks

- Measuring gears to ensure they meet the required dimensions and tolerances

- Checking gears for defects, such as burrs and cracks

- Maintaining quality control records

3. Troubleshooting

Identifying and resolving problems with gear generating machines. This may involve diagnosing the problem, making repairs, and adjusting the machine’s settings

- Troubleshooting machine problems

- Making repairs to the machine

- Adjusting the machine’s settings

4. Training

Training new operators on how to use gear generating machines. This may involve providing instruction on machine setup, operation, and maintenance

- Training new operators on how to use gear generating machines

- Providing instruction on machine setup, operation, and maintenance

Interview Tips

To ace your interview for a Gear Generator Set Up Operator position, it’s important to be prepared. Here are a few tips:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the specific position you’re applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the job. You can find this information on the company’s website, LinkedIn, and other online resources.

- Visit the company’s website to learn about their history, products, and services.

- Check out the company’s social media pages to get a sense of their culture and values.

- Read online reviews of the company to see what current and former employees have to say about working there.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you’re likely to be asked, regardless of the position you’re applying for. It’s a good idea to practice answering these questions ahead of time so that you can deliver confident and well-thought-out responses. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills as they relate to the position you’re applying for. Be prepared to talk about your work history, your technical skills, and your soft skills. You should also be able to provide examples of your work that demonstrate your skills and abilities.

- Highlight your experience setting up and operating gear generating machines.

- Describe your skills in quality control and troubleshooting.

- Provide examples of your work that demonstrate your attention to detail and your ability to meet deadlines.

4. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re serious about the position and that you respect their time. When you arrive for your interview, be sure to greet the interviewer with a firm handshake and make eye contact. You should also be prepared to answer questions about your experience and qualifications.

- Dress in business attire.

- Arrive on time for your interview.

- Greet the interviewer with a firm handshake and make eye contact.

Next Step:

Now that you’re armed with the knowledge of Gear Generator Set Up Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Gear Generator Set Up Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini