Are you gearing up for a career in Gear Grinder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Gear Grinder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

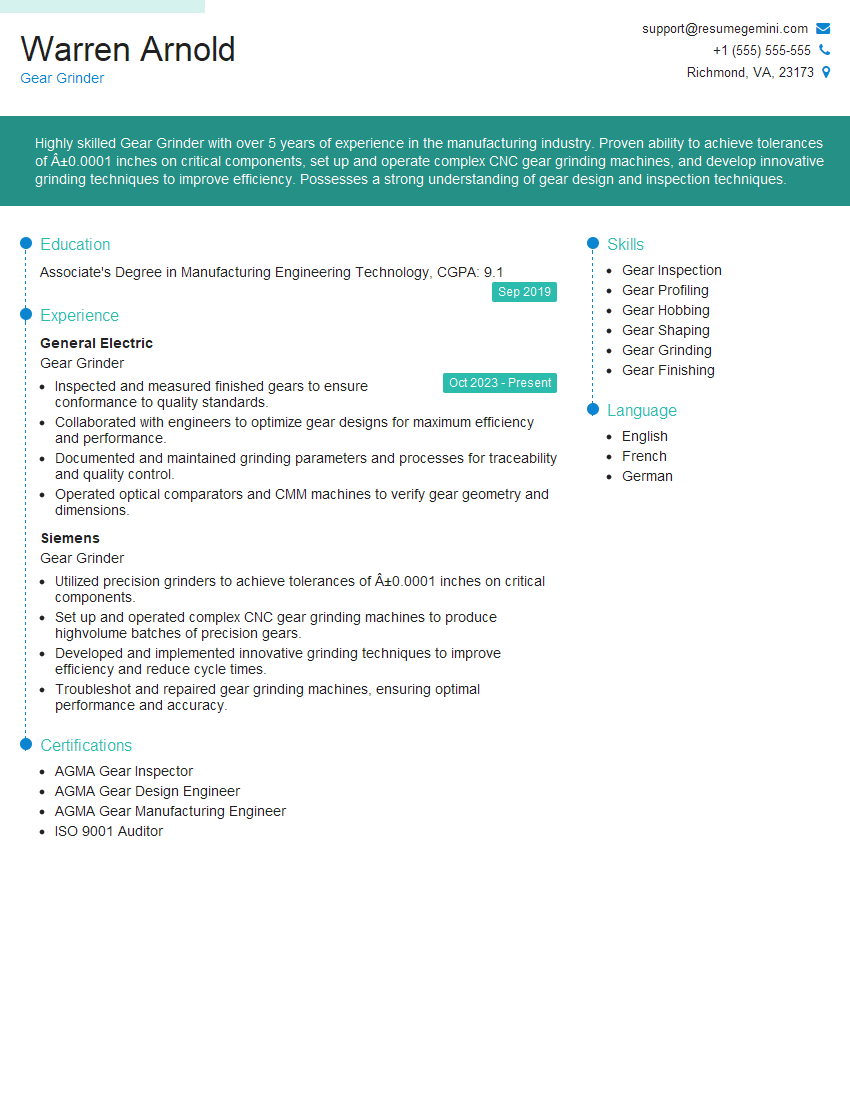

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Grinder

1. What are the different types of gear grinding machines?

There are three main types of gear grinding machines:

- Form grinding: This method uses a grinding wheel that is dressed to the desired tooth shape. The wheel is then fed into the workpiece, and the teeth are ground to the desired profile.

- Generating grinding: This method uses a grinding wheel that is crowned to the desired tooth shape. The wheel is then fed into the workpiece, and the teeth are ground to the desired profile by the relative motion of the wheel and the workpiece.

- Profile grinding: This method uses a grinding wheel that is dressed to the desired tooth shape. The wheel is then fed into the workpiece, and the teeth are ground to the desired profile by the relative motion of the wheel and the workpiece.

2. What are the advantages and disadvantages of each type of gear grinding machine?

Form grinding

- Advantages:

- High accuracy

- Good surface finish

- Can grind complex tooth shapes

- Disadvantages:

- Slow

- Expensive

- Requires skilled operators

Generating grinding

- Advantages:

- Fast

- Inexpensive

- Easy to operate

- Disadvantages:

- Lower accuracy than form grinding

- Poorer surface finish than form grinding

- Cannot grind complex tooth shapes

Profile grinding

- Advantages:

- Combination of the advantages of form grinding and generating grinding

- Disadvantages:

- More expensive than generating grinding

- More difficult to operate than generating grinding

3. What are the different types of grinding wheels that can be used for gear grinding?

The following types of grinding wheels can be used for gear grinding:

- Vitrified bond wheels: These wheels are made of abrasive grains that are bonded together with a vitrified bond. They are hard and durable, and they can be used for grinding a wide variety of materials.

- Electroplated diamond wheels: These wheels are made of diamond particles that are electroplated onto a metal core. They are very hard and wear-resistant, and they can be used to grind hard materials such as carbide.

- CBN wheels: These wheels are made of cubic boron nitride (CBN) particles that are bonded together with a resin or metal bond. They are very hard and wear-resistant, and they can be used to grind hard materials such as steel and titanium.

4. What are the different factors that affect the quality of a gear grinding operation?

The following factors affect the quality of a gear grinding operation:

- Machine tool: The accuracy and rigidity of the machine tool will affect the accuracy and surface finish of the ground gear.

- Grinding wheel: The type, size, and condition of the grinding wheel will affect the accuracy, surface finish, and productivity of the grinding operation.

- Workpiece: The material, hardness, and geometry of the workpiece will affect the grinding parameters and the quality of the ground gear.

- Grinding parameters: The speed, feed, and depth of cut will affect the accuracy, surface finish, and productivity of the grinding operation.

5. What are the different types of gear inspection methods?

The following types of gear inspection methods are commonly used:

- Visual inspection: This method is used to inspect the gear for obvious defects such as cracks, chips, and burrs.

- Dimensional inspection: This method is used to measure the dimensions of the gear, such as the tooth pitch, tooth thickness, and tooth profile.

- Functional inspection: This method is used to test the gear for its ability to function properly, such as by measuring its noise level and vibration.

6. What are the different types of gear materials?

The following types of gear materials are commonly used:

- Steel: Steel is a strong and durable material that is often used for gears that are subjected to high loads.

- Cast iron: Cast iron is a less expensive material than steel, and it is often used for gears that are not subjected to high loads.

- Bronze: Bronze is a wear-resistant material that is often used for gears that are subjected to high sliding contact.

- Plastic: Plastic is a lightweight and inexpensive material that is often used for gears that are subjected to low loads.

7. What are the different types of gear applications?

Gears are used in a wide variety of applications, including:

- Automotive

- Aerospace

- Industrial machinery

- Medical devices

- Robotics

8. What are the different types of gear tooth profiles?

The following types of gear tooth profiles are commonly used:

- Involute: This is the most common type of gear tooth profile. It is a smooth, continuous curve that provides good tooth contact and low noise levels.

- Cycloidal: This type of gear tooth profile has a unique shape that provides for a very smooth, quiet, and efficient operation.

- Herringbone: This type of gear tooth profile is made up of two opposite-handed involute profiles. It provides for a very strong and durable gear.

9. What are the different types of gear tooth modifications?

The following types of gear tooth modifications are commonly used:

- Chamfering: This is a simple modification that involves rounding the sharp edges of the gear teeth. It helps to reduce stress concentrations and improve the fatigue strength of the gear.

- Crowning: This modification involves slightly curving the tooth surface in the axial direction. It helps to improve the tooth contact and reduce noise levels.

- Tapering: This modification involves slightly tapering the tooth surface in the radial direction. It helps to improve the load distribution and reduce the possibility of edge loading.

10. What are the different types of gear heat treatments?

The following types of gear heat treatments are commonly used:

- Annealing: This process involves heating the gear to a high temperature and then slowly cooling it. It helps to soften the gear and improve its ductility.

- Hardening: This process involves heating the gear to a high temperature and then rapidly cooling it. It helps to increase the hardness and strength of the gear.

- Tempering: This process involves heating the gear to a temperature below the hardening temperature and then holding it at that temperature for a period of time. It helps to relieve internal stresses and improve the toughness of the gear.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gear Grinders play a critical role in the manufacturing industry, responsible for shaping and finishing gears used in various machinery. Their key responsibilities include:

1. Gear Production and Inspection

Producing gears according to precise specifications using specialized grinding equipment.

- Interpreting technical drawings and following established procedures.

- Selecting and setting up appropriate grinding wheels and tools.

- Monitoring and adjusting grinding parameters to achieve desired tolerances and surface finishes.

- Conducting post-grinding inspections using precision measuring instruments to ensure accuracy.

2. Machine Setup and Maintenance

Setting up, operating, and maintaining grinding machines efficiently.

- Installing and aligning grinding wheels, fixtures, and other components.

- Calibrating and adjusting machine settings for optimal performance.

- Performing routine maintenance tasks, including lubrication, cleaning, and troubleshooting.

- Recognizing potential problems and taking preventive measures to minimize downtime.

3. Quality Assurance and Continuous Improvement

Ensuring the quality of gears produced and contributing to process improvement initiatives.

- Conducting regular checks and inspections to identify and correct production issues.

- Analyzing data to identify areas for improvement in productivity, efficiency, and quality.

- Collaborating with other team members to implement process enhancements and resolve manufacturing challenges.

- Complying with established quality standards and industry best practices.

4. Safety and Compliance

Maintaining a safe work environment and adhering to all applicable safety regulations.

- Following established safety protocols and wearing appropriate personal protective equipment.

- Identifying and reporting potential hazards and implementing corrective actions.

- Understanding and complying with environmental regulations related to grinding operations.

- Participating in safety training and staying up-to-date on industry best practices.

Interview Tips

To ace the interview for a Gear Grinder position, consider these tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the manufacturing industry by researching their products, services, and recent developments in gear grinding technology.

- Visit the company’s website and social media pages.

- Read industry publications and attend trade shows.

- Network with professionals in the field.

2. Highlight Your Technical Skills

Emphasize your proficiency in gear grinding techniques, equipment handling, and precision measuring. Provide specific examples of your experience in grinding different types of gears and meeting tight tolerances.

- Quantify your accomplishments whenever possible, using metrics like production output, defect rates, or efficiency improvements.

- Be prepared to discuss your understanding of grinding principles, grinding wheel selection, and troubleshooting common issues.

3. Showcase Your Problem-Solving Abilities

Share examples of how you effectively identified and resolved problems in previous roles. Highlighting your analytical skills, attention to detail, and ability to think creatively will demonstrate your value as a problem-solver.

- Describe a situation where you discovered a manufacturing defect and implemented a solution to prevent future occurrences.

- Explain how you improved a process by optimizing machine settings or developing new techniques.

4. Emphasize Safety and Compliance

Consistently following safety protocols is crucial in a manufacturing environment. Assure the interviewer that you prioritize safety and have a deep understanding of industry regulations.

- Discuss your experience in maintaining a clean and organized work area.

- Highlight your knowledge of proper machine operation and maintenance procedures.

5. Be Enthusiastic and Professional

Show genuine interest in the Gear Grinder position and the opportunity to contribute to the company’s success. Maintain a professional demeanor throughout the interview and ask thoughtful questions to demonstrate your engagement.

- Express your eagerness to learn and grow within the team.

- Inquire about the company’s future plans and how your skills can align with those goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gear Grinder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.