Are you gearing up for a career in Gear Hobber Set-Up Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Gear Hobber Set-Up Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

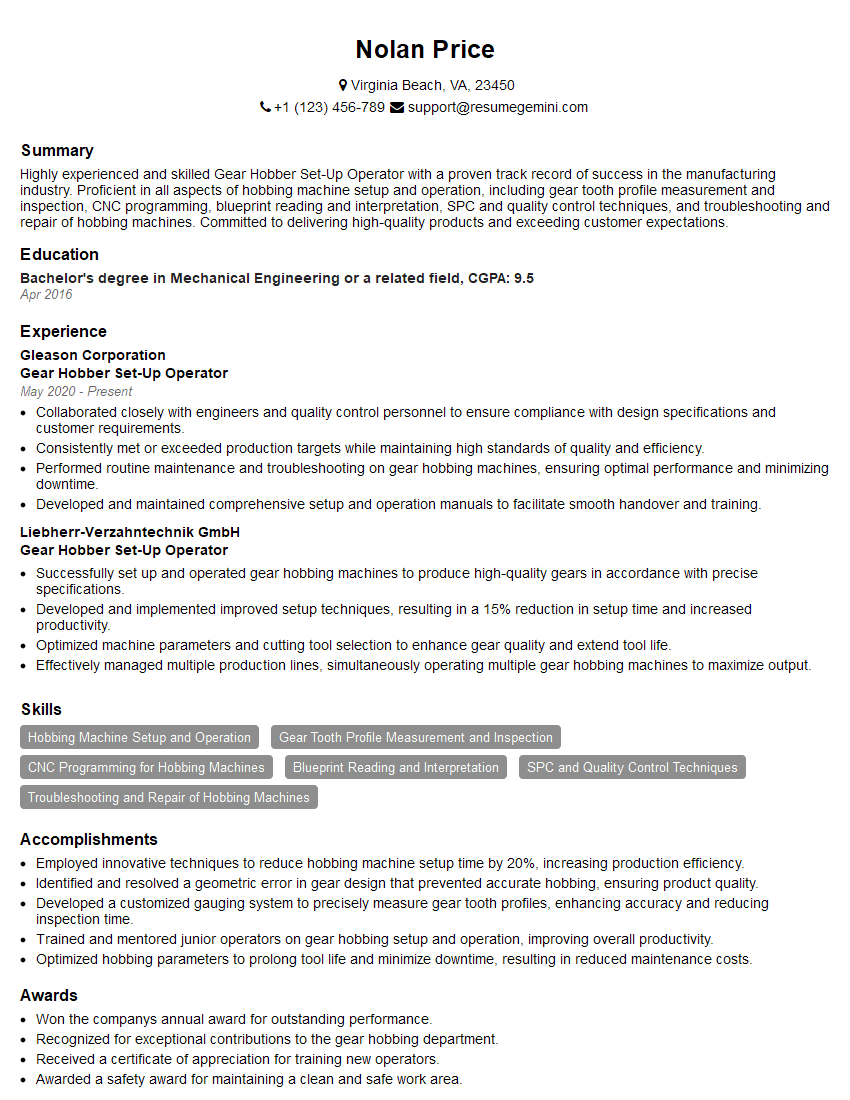

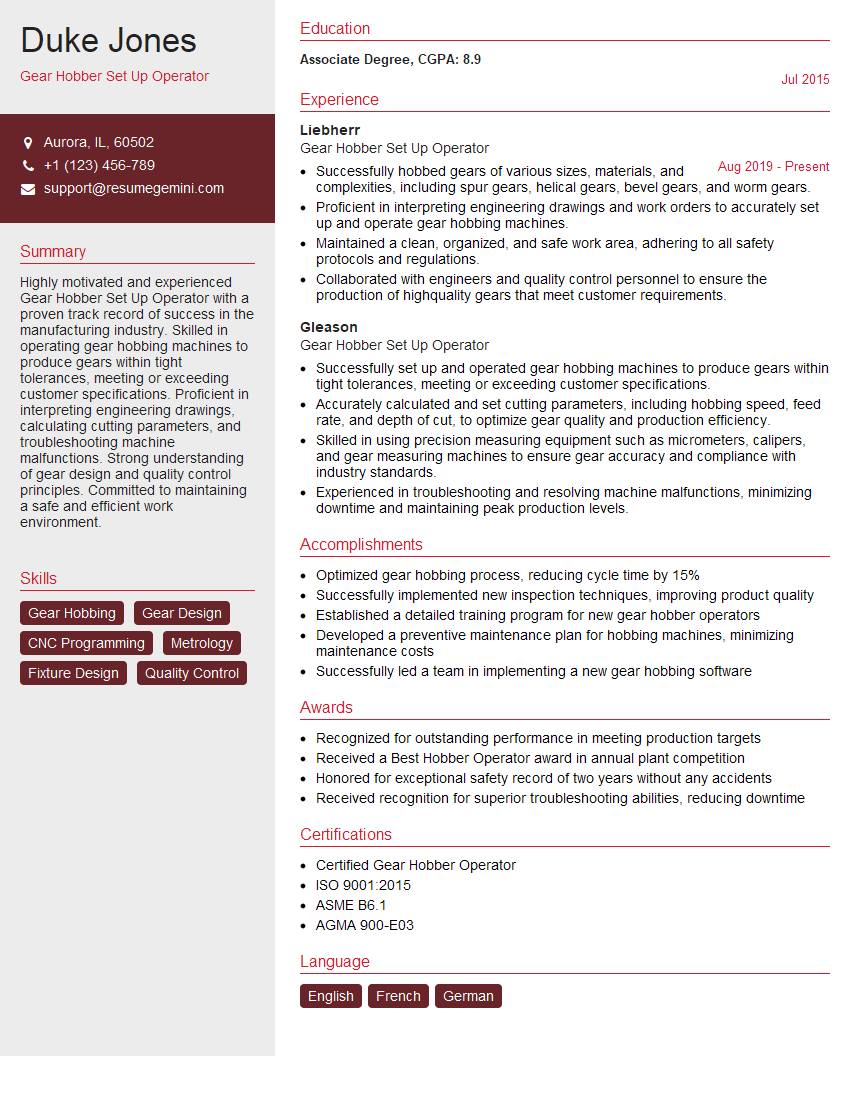

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Hobber Set-Up Operator

1. Explain the process of setting up a gear hobber machine for a specific gear cutting operation.

The process of setting up a gear hobber machine for a specific gear cutting operation involves the following steps:

- Mounting the workpiece: The workpiece is mounted on the machine table using a suitable workholding device.

- Mounting the hob: The hob is mounted on the hob arbor and secured using a collet or other clamping mechanism.

- Setting the cutting parameters: The cutting parameters, such as the feed rate, hob speed, and depth of cut, are set according to the workpiece material, gear specifications, and machine capabilities.

- Checking the setup: The setup is checked for accuracy using a dial indicator or other measuring instrument to ensure that the hob and workpiece are correctly aligned.

2. Describe the different types of hobs used in gear hobbing and explain their applications.

Types of hobs

- Straight hobs: Used for cutting spur gears and helical gears with straight teeth.

- Helical hobs: Used for cutting helical gears with angled teeth.

- Involute hobs: Used for cutting gears with involute tooth profiles.

- Conical hobs: Used for cutting bevel gears.

- Worm hobs: Used for cutting worms and worm gears.

Applications of hobs

- Straight hobs: Automotive gears, power transmission gears, machine tool gears.

- Helical hobs: Automotive gears, power transmission gears, marine gears.

- Involute hobs: Aerospace gears, medical devices.

- Conical hobs: Automotive differentials, bevel gears.

- Worm hobs: Worm drives, power steering systems.

3. Explain the principles of gear cutting and how the hobber machine achieves the desired gear profile.

Gear cutting is a machining process that uses a rotating cutting tool, called a hob, to create gear teeth on a workpiece. The hob has a series of cutting edges that are shaped to match the desired gear tooth profile. As the hob rotates, it feeds into the workpiece, removing material and creating the gear teeth. The hobber machine controls the movement of the hob and the workpiece to achieve the desired gear profile.

4. Describe the different methods for checking the accuracy of gear hobbing operations.

- Dial indicator: Used to measure the runout of the gear, tooth thickness, and tooth profile.

- Gear tooth micrometer: Used to measure the tooth thickness.

- Gear profile projector: Used to project the gear profile onto a screen for inspection.

- Coordinate measuring machine (CMM): Used to measure various dimensions of the gear, including tooth profile, runout, and tooth thickness.

5. Explain the importance of coolant in gear hobbing operations and describe the different types of coolants used.

- Cooling: Coolant helps to dissipate heat generated during the cutting process, preventing thermal damage to the hob and workpiece.

- Lubrication: Coolant provides lubrication between the hob and workpiece, reducing friction and wear.

- Chip removal: Coolant helps to flush away chips from the cutting zone, preventing them from clogging the hob and workpiece.

Types of coolants used in gear hobbing operations include:

- Soluble oil: A mixture of oil and water that provides cooling and lubrication.

- Synthetic coolants: Formulated specifically for gear hobbing operations, providing superior cooling and lubrication properties.

- Cryogenic coolants: Such as liquid nitrogen, provide extreme cooling and lubrication, resulting in reduced tool wear and improved surface finish.

6. Describe the maintenance procedures for gear hobber machines, including lubrication, cleaning, and inspection.

- Lubrication: Lubricate all moving parts of the machine, including bearings, gears, and slides, according to the manufacturer’s specifications.

- Cleaning: Clean the machine regularly to remove chips, coolant, and other contaminants that can affect its performance.

- Inspection: Inspect the machine regularly for any signs of wear or damage, such as worn bearings, damaged gears, or misaligned components.

7. Explain the factors that affect the quality of gear hobbing operations, such as hob sharpness, feed rate, and cutting speed.

- Hob sharpness: A sharp hob produces clean cuts and results in a better surface finish on the gears.

- Feed rate: The feed rate determines the amount of material removed per tooth of the hob. A higher feed rate can lead to faster cutting but may also reduce the quality of the gears.

- Cutting speed: The cutting speed determines the velocity of the hob teeth relative to the workpiece. A higher cutting speed can lead to faster cutting but may also generate more heat and reduce the life of the hob.

8. Describe the different types of gear hobbing machines, such as vertical and horizontal hobbers.

Vertical hobbers

- The workpiece is mounted on a vertical axis.

- The hob is mounted on a horizontal axis.

- Suitable for cutting spur gears, helical gears, and worm gears.

Horizontal hobbers

- The workpiece is mounted on a horizontal axis.

- The hob is mounted on a vertical axis.

- Suitable for cutting large gears, bevel gears, and hypoid gears.

9. Explain the role of automation in gear hobbing operations and describe the different types of automated systems used.

- CNC (Computer Numerical Control): CNC systems use computer programs to control the movement of the machine, enabling automatic operation and improved accuracy.

- PLC (Programmable Logic Controller): PLCs are programmable controllers that can be used to automate the operation of the machine, including hob selection, workpiece loading, and coolant management.

- Robots: Robots can be used to automate the loading and unloading of workpieces, reducing the need for manual labor.

10. Discuss the latest trends and advancements in gear hobbing technology.

- High-speed hobbing: Techniques that enable faster cutting speeds, reducing cycle times and improving productivity.

- Dry hobbing: Techniques that eliminate the use of coolant during gear hobbing, reducing environmental impact and improving surface finish.

- Advanced hob designs: Hobs with specialized coatings and geometries that improve cutting efficiency and extend tool life.

- Integrated gear hobbing systems: Systems that combine gear hobbing with other operations, such as gear shaving and grinding, in a single setup, reducing manufacturing time and improving efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Hobber Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Hobber Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gear Hobber Set-Up Operators play a crucial role in the manufacturing process by preparing and operating gear hobbing machines. They ensure that the machines are set up accurately to produce high-quality gears. Key job responsibilities include:

1. Machine Setup

Preparing and setting up gear hobbing machines, including mounting cutting tools, adjusting machine parameters, and verifying accuracy.

- Reading and interpreting blueprints and work orders to determine machine setup requirements.

- Selecting and installing the appropriate cutting tools and work holding fixtures.

2. Machine Operation

Monitoring and operating gear hobbing machines to produce gears according to specifications.

- Supervising the gear hobbing process to ensure smooth operation and adherence to quality standards.

- Adjusting machine settings and parameters during operation to maintain optimal performance.

3. Inspection and Quality Control

Conducting in-process and final inspections of gears to ensure they meet dimensional tolerances and specifications.

- Using measuring tools and gauges to verify gear dimensions, tooth profiles, and surface finish.

- Identifying and correcting any deviations from specifications.

4. Machine Maintenance

Performing routine maintenance and troubleshooting on gear hobbing machines.

- Cleaning and lubricating machines to ensure proper operation.

- Identifying and resolving minor mechanical or electrical issues.

Interview Tips

To prepare effectively for an interview as a Gear Hobber Set-Up Operator, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, products or services, and industry reputation. Research the specific job requirements and responsibilities.

- Review the company’s website, LinkedIn page, and industry publications.

- Identify the key skills and qualifications required for the position.

2. Highlight Relevant Skills and Experience

Emphasize your experience and skills that are directly related to the responsibilities of a Gear Hobber Set-Up Operator. Quantify your accomplishments whenever possible.

- Describe your experience in setting up and operating gear hobbing machines.

- Provide examples of how you have ensured accuracy and quality in your work.

3. Demonstrate Understanding of Gear Hobbing Process

Show that you have a thorough understanding of the gear hobbing process, including the principles of machine operation, cutting tool selection, and inspection techniques.

- Explain the different types of gear hobbing machines and their applications.

- Describe the factors that influence gear quality, such as cutting speed, feed rate, and tooth profile.

4. Showcase Problem-Solving Abilities

Gear Hobber Set-Up Operators often encounter unexpected issues. Highlight your problem-solving abilities and provide examples of how you have successfully resolved technical challenges.

- Describe a situation where you identified and resolved a problem with a gear hobbing machine.

- Explain how you analyzed the issue, developed a solution, and implemented it effectively.

5. Practice and Prepare

Practice answering common interview questions and anticipate potential technical questions related to gear hobbing. Prepare clear and concise responses that showcase your knowledge and skills.

- Research common interview questions for Gear Hobber Set-Up Operators.

- Practice your answers out loud or with a friend or family member.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gear Hobber Set-Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!