Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Gear Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Gear Inspector so you can tailor your answers to impress potential employers.

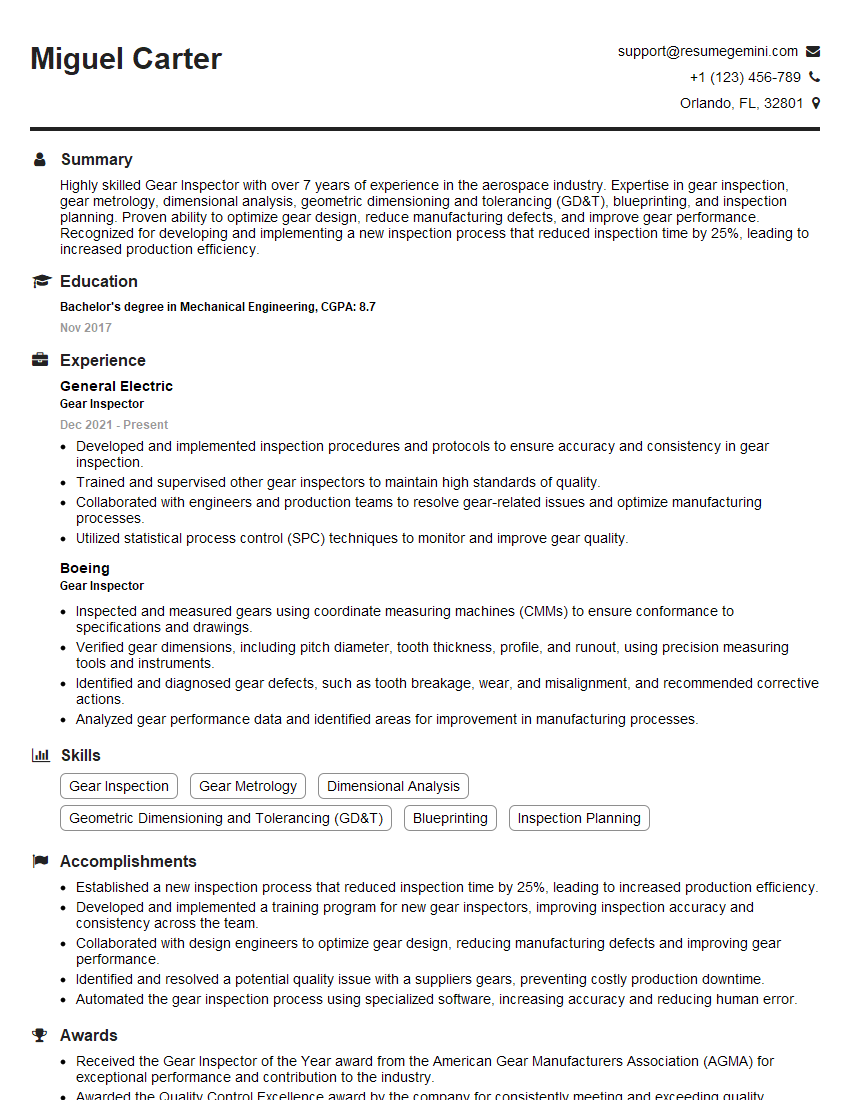

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Inspector

1. Describe the steps involved in inspecting gears?

Gear Inspection Procedure

- Visual inspection of the gear for any obvious defects, such as cracks, chips, or burrs.

- Measurement of the gear’s dimensions, such as diameter, thickness, and tooth profile.

- Testing of the gear’s hardness and strength.

- Examination of the gear’s surface finish.

- Creation of a report detailing the results of the inspection.

2. What are the different types of gear inspection gauges?

Types of Gear Inspection Gauges

- Tooth profile gauges

- Pitch diameter gauges

- Runout gauges

- Lead gauges

- Composite gauges

3. What are the most common gear defects?

Common Gear Defects

- Tooth breakage

- Tooth wear

- Pitting

- Spalling

- Scoring

4. What are the causes and effects of gear noise?

Causes and Effects of Gear Noise

- Causes: Misalignment, improper lubrication, worn gears, and excessive backlash.

- Effects: Increased vibration, reduced efficiency, and premature gear failure.

5. How do you inspect gears for surface finish?

Gear Surface Finish Inspection Methods

- Visual inspection

- Microscopic inspection

- Stylus profilometry

- Optical profilometry

- Atomic force microscopy

6. What are the different types of gear materials?

Types of Gear Materials

- Steel

- Cast iron

- Bronze

- Aluminum

- Plastic

7. How do you calculate the gear ratio?

Gear Ratio Calculation

- Divide the number of teeth on the driven gear by the number of teeth on the driving gear.

8. What is the difference between a spur gear and a helical gear?

Spur Gear vs. Helical Gear

- Spur gears have straight teeth, while helical gears have slanted teeth.

- Helical gears are quieter and smoother running than spur gears.

- Helical gears can transmit more power than spur gears.

9. What are the advantages of using gear inspection software?

Advantages of Gear Inspection Software

- Automated inspection process

- Reduced inspection time

- Improved accuracy and consistency

- Generation of detailed inspection reports

10. How do you stay up-to-date on the latest gear inspection techniques?

Keeping Up-to-Date on Gear Inspection Techniques

- Attend industry conferences and workshops.

- Read trade journals and magazines.

- Network with other gear inspectors.

- Take online courses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Gear Inspector is primarily responsible for inspecting and evaluating gears to ensure compliance with specified standards and requirements. Their duties encompass a wide range of tasks that contribute to maintaining the quality and functionality of gears used in various industries.

1. Gear Inspection and Evaluation

Involves thoroughly inspecting gears for defects, deviations, or any non-conformities using specialized equipment such as gear measuring machines, coordinate measuring machines, or optical comparators. They may also perform hardness testing, dimensional measurements, and surface finish analysis to verify conformance to specifications.

- Identify and report any deviations or discrepancies from established standards.

- Use various measurement techniques and instruments to assess gear characteristics such as tooth profile, pitch, backlash, and runout.

2. Quality Control and Assurance

Ensure that gears meet quality standards by implementing inspection procedures and following established protocols. They may also analyze inspection data, identify trends, and make recommendations for process improvements to enhance quality.

- Adhere to quality control procedures and maintain accurate records of inspection results.

- Calibrate and maintain inspection equipment to ensure accuracy and reliability.

3. Data Analysis and Reporting

Analyze inspection data to identify quality issues, determine root causes, and develop corrective actions. They may also prepare reports summarizing inspection findings and communicate results to relevant stakeholders.

- Compile inspection data and generate reports for internal and external use.

- Identify areas for improvement based on data analysis and industry best practices.

4. Collaboration and Communication

Effectively interact with engineers, production personnel, and quality managers to provide feedback, resolve issues, and ensure alignment with quality objectives.

- Collaborate with design engineers to optimize gear design and manufacturing processes.

- Communicate inspection results and recommendations to production teams for timely corrective action.

Interview Tips

Preparing for an interview for a Gear Inspector position requires a combination of technical knowledge, industry expertise, and effective communication skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

ознакомьтесь с компанией, в которую вы устраиваетесь, и ее отраслью, чтобы продемонстрировать свою заинтересованность и понимание. Узнайте о тенденциях отрасли, последних технологиях и лучших практиках в области контроля качества. Используйте эту информацию, чтобы связать свои навыки и опыт с потребностями компании.

- Visit the company’s website to learn about its products, services, and quality standards.

- Read industry publications and attend webinars to stay updated on the latest gear inspection techniques.

2. Highlight Your Technical Skills and Experience

Emphasize your proficiency in gear inspection methods and equipment. Quantify your experience in using measuring machines, optical comparators, and other relevant tools. Share examples of how you have applied your skills to identify and resolve gear defects.

- Describe your experience in using different gear measurement techniques such as profile measurements, tooth spacing measurements, and runout checks.

- Provide specific examples of how you have identified and resolved gear defects, leading to improved product quality.

3. Demonstrate Your Quality Control Expertise

Showcase your understanding of quality control procedures and protocols. Explain how you have implemented and maintained quality management systems in previous roles. Discuss your ability to analyze inspection data, identify trends, and recommend corrective actions to enhance gear quality.

- Explain your understanding of ISO 9001 or other relevant quality standards.

- Describe how you have used statistical process control (SPC) techniques to monitor and improve gear production processes.

4. Prepare for Common Interview Questions

Research common interview questions related to gear inspection and prepare thoughtful answers that highlight your capabilities. Be prepared to discuss your experience in identifying and resolving gear defects, your knowledge of gear inspection equipment, and your approach to quality control and assurance. Example Outline:

- Tell me about your experience in gear inspection.

- Describe a challenging gear inspection project you have worked on.

- How do you ensure the accuracy and reliability of your inspection results?

5. Emphasize Your Communication and Collaboration Skills

Highlight your ability to effectively communicate inspection results, collaborate with engineers and production teams, and resolve issues in a timely manner. Provide examples of how you have worked with cross-functional teams to improve gear quality.

- Describe your experience in presenting inspection findings to engineers and production managers.

- Explain how you have collaborated with design engineers to optimize gear design and manufacturing processes.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Gear Inspector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Gear Inspector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.