Are you gearing up for a career in Gear Lapping Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Gear Lapping Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

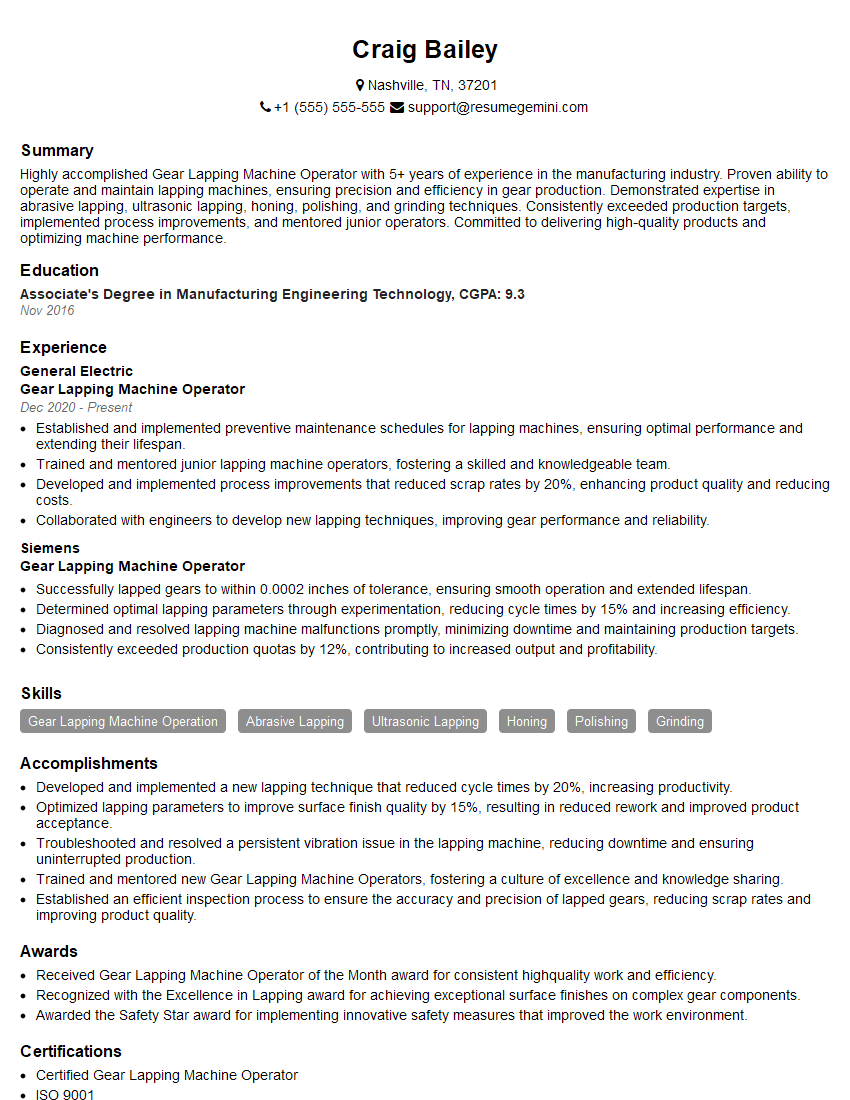

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Lapping Machine Operator

1. Explain the process of gear lapping.

Gear lapping is a precision machining process used to improve the surface finish and dimensional accuracy of gears. It involves rubbing two gears together with an abrasive compound, removing material from the surfaces until they reach the desired specifications. The process is typically performed on high-precision gears used in critical applications such as aerospace and automotive.

2. What are the different types of gear lapping machines?

- Horizontal lapping machines: These machines hold the gears horizontally and rotate them in opposite directions. They are typically used for lapping spur gears and helical gears.

- Vertical lapping machines: These machines hold the gears vertically and rotate them in the same direction. They are typically used for lapping bevel gears and hypoid gears.

3. What are the factors that affect the quality of the lapped surface?

- Abrasive compound: The type and size of the abrasive compound used will affect the surface roughness and material removal rate.

- Lapping pressure: The amount of pressure applied to the gears during lapping will affect the surface finish and dimensional accuracy.

- Lapping speed: The speed at which the gears are rotated during lapping will affect the surface finish and material removal rate.

- Lapping time: The duration of the lapping process will affect the surface finish and dimensional accuracy.

4. What are the common problems that can occur during gear lapping?

- Gear chatter: This can occur when the gears are not properly aligned or the lapping parameters are not optimized, leading to excessive vibration and noise.

- Scoring: This can occur when the abrasive compound is too coarse or the lapping pressure is too high, leading to scratches or gouges on the gear surfaces.

- Burning: This can occur when the lapping speed is too high or the lapping time is too long, leading to excessive heat buildup and damage to the gear surfaces.

5. What are the maintenance procedures for a gear lapping machine?

- Regular cleaning of the machine and its components.

- Lubrication of all moving parts.

- Inspection and replacement of worn or damaged parts.

- Calibration of the machine to ensure accuracy and precision.

6. What are the safety precautions that should be taken when operating a gear lapping machine?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Ensure the machine is properly guarded and maintained.

- Follow all operating procedures and instructions.

- Be aware of potential hazards and take appropriate precautions.

7. What are the quality control procedures for gear lapping?

- Visual inspection of the lapped surfaces for defects.

- Dimensional measurement of the gears to ensure they meet specifications.

- Surface roughness measurement to verify the desired surface finish.

- Gear noise testing to assess the quality of the gear mesh.

8. What are the troubleshooting techniques for gear lapping problems?

- Identify the problem and its potential causes.

- Inspect the machine and its components for any issues.

- Adjust the lapping parameters and try different abrasive compounds.

- Consult with experienced technicians or manufacturers for guidance.

9. What are the latest trends in gear lapping technology?

- Automation of the lapping process.

- Use of advanced abrasive compounds and lapping techniques.

- Development of new machine designs for improved efficiency and precision.

- Integration of sensors and monitoring systems for real-time process control.

10. What are the career prospects for a gear lapping machine operator?

With experience and skills, a gear lapping machine operator can advance to roles such as lead operator, supervisor, or quality control inspector. They can also specialize in different areas of gear manufacturing, such as gear design, engineering, or sales.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Lapping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Lapping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Gear Lapping Machine Operator is responsible for operating and maintaining gear lapping machines to produce high-quality gears for various industries. Their key responsibilities include:

1. Machine Operation

intro paragraph

- Loading and unloading workpieces onto the gear lapping machine.

- Setting up and adjusting the machine according to specifications.

- Monitoring the lapping process and making adjustments as necessary.

- Inspecting finished gears for quality and accuracy.

2. Machine Maintenance

intro paragraph

- Performing routine maintenance on the gear lapping machine, including lubrication and cleaning.

- Troubleshooting and repairing minor machine malfunctions.

- Reporting major machine issues to supervisors for further action.

3. Process Improvement

intro paragraph

- Identifying and implementing ways to improve the lapping process, such as optimizing cycle times or reducing scrap.

- Working with engineers and other team members to develop new lapping techniques.

4. Quality Control

intro paragraph

- Adhering to quality standards and procedures.

- Conducting statistical process control (SPC) to monitor and maintain process quality.

- Documenting and reporting quality data as required.

Interview Tips

Preparing for a job interview as a Gear Lapping Machine Operator requires careful preparation and a solid understanding of the role. Here are some tips to help you ace the interview:

1. Research the Company and the Position

Familiarize yourself with the company’s history, values, and products. Research the specific job requirements and responsibilities to demonstrate your understanding of the role.

2. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses.” Practice your answers aloud to build confidence and improve your delivery.

3. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining gear lapping machines. Showcase your knowledge of lapping techniques, quality control processes, and troubleshooting procedures.

4. Share Examples of Your Successes

Provide specific examples of your accomplishments in previous roles, particularly those related to improving process efficiency or maintaining high-quality standards. Quantify your results whenever possible to demonstrate your impact.

5. Ask Thoughtful Questions

Toward the end of the interview, ask thoughtful questions about the company, the position, or the industry. This shows your interest in the opportunity and your desire to learn more.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gear Lapping Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.