Are you gearing up for an interview for a Gear Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Gear Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

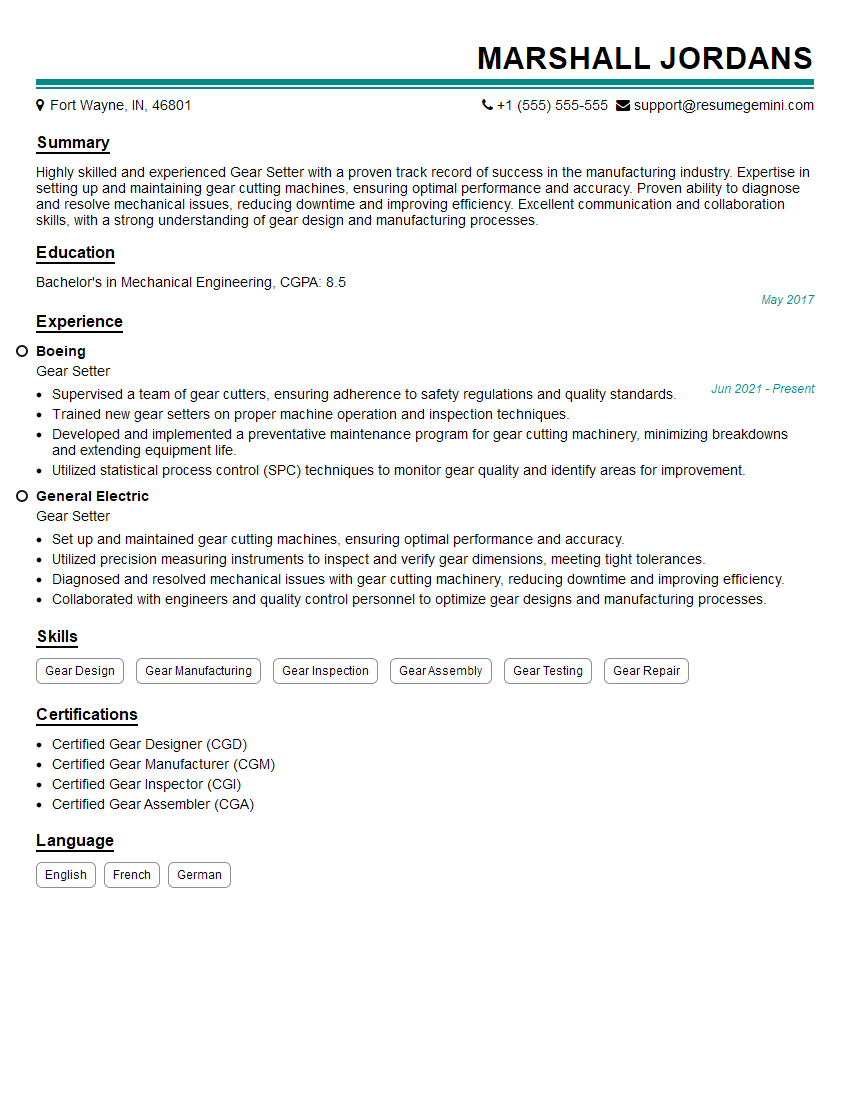

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Setter

1. Explain the process of setting up a gear hobbing machine?

The process of setting up a gear hobbing machine involves several steps:

- Mounting the workpiece: The workpiece is secured to the table of the machine using a chuck or collet.

- Installing the hob: The hob is mounted on the hob arbor and aligned with the workpiece.

- Setting the machine parameters: The machine parameters, such as the spindle speed, feed rate, and depth of cut, are set according to the workpiece and hob specifications.

- Lubrication: The hob and workpiece are lubricated to reduce friction and heat generation.

- Trial cut: A trial cut is performed to ensure that the machine is set up correctly and to fine-tune the parameters.

2. How do you determine the correct hob for a given gear?

The correct hob for a given gear is determined based on several factors:

- Number of teeth: The number of teeth on the hob must match the number of teeth on the gear.

- Module: The module of the hob and gear must be the same.

- Pressure angle: The pressure angle of the hob and gear must be the same.

- Material: The hob material must be compatible with the gear material.

- Diameter: The diameter of the hob must be appropriate for the size of the gear.

3. What are the common types of gear hobbing machines?

The common types of gear hobbing machines include:

- Horizontal hobbing machines: The workpiece is mounted horizontally and the hob is mounted vertically.

- Vertical hobbing machines: The workpiece is mounted vertically and the hob is mounted horizontally.

- Universal hobbing machines: These machines can be used for both horizontal and vertical hobbing.

- CNC gear hobbing machines: These machines are computer-controlled and offer high precision and efficiency.

4. How can you troubleshoot a gear hobbing machine if it is producing defective gears?

Troubleshooting a gear hobbing machine if it is producing defective gears can involve the following steps:

- Check the machine setup: Ensure that the workpiece is properly mounted, the hob is correctly aligned, and the machine parameters are set accurately.

- Inspect the hob: Check for any damage or wear on the hob, as this can affect the quality of the gears.

- Examine the workpiece: Check the workpiece for any defects or imperfections, as these can also lead to defective gears.

- Review the lubrication: Ensure that the hob and workpiece are properly lubricated, as insufficient lubrication can cause excessive wear and tear.

- Calibrate the machine: Perform a calibration of the machine to ensure that it is operating within the required tolerances.

5. What are the safety precautions that must be observed when operating a gear hobbing machine?

When operating a gear hobbing machine, it is important to observe the following safety precautions:

- Wear appropriate safety gear: This includes safety glasses, earplugs, and gloves.

- Keep the work area clean and organized: This helps prevent accidents and ensures efficient operation.

- Securely mount the workpiece and hob: This prevents them from becoming loose and causing injury.

- Be aware of moving parts: Keep your hands and other body parts away from moving parts of the machine.

- Follow proper lockout/tagout procedures: This ensures that the machine is de-energized before performing maintenance or repairs.

6. Explain the difference between a spur gear and a helical gear?

Spur gears:

- Have teeth that are parallel to the axis of rotation.

- Transmit power between parallel shafts.

- Produce less noise and vibration compared to helical gears.

Helical gears:

- Have teeth that are cut at an angle to the axis of rotation.

- Transmit power between parallel or intersecting shafts.

- Produce more noise and vibration compared to spur gears, but offer smoother transmission of power.

7. What are the different types of gear materials?

The common types of gear materials include:

- Steel: Steel gears are strong, durable, and wear-resistant.

- Cast iron: Cast iron gears are strong, inexpensive, and can handle high loads.

- Bronze: Bronze gears are corrosion-resistant and offer good wear resistance.

- Plastic: Plastic gears are lightweight, quiet, and can be used in low-load applications.

- Composite materials: Composite gears offer a combination of strength, wear resistance, and lightweight properties.

8. How do you calculate the gear ratio of a gear pair?

The gear ratio of a gear pair is calculated using the following formula:

Gear ratio = Number of teeth on driven gear / Number of teeth on driving gear

The gear ratio determines the speed and torque relationship between the gears.

9. What is the purpose of a gear hob?

A gear hob is a cutting tool used to cut the teeth on gears. It is a rotating cutter with multiple cutting edges that are shaped to match the desired gear tooth profile. The hob is rotated and fed into the workpiece, gradually cutting the teeth into the material.

10. Explain the process of gear grinding?

Gear grinding is a finishing process that removes small amounts of material from the surface of a gear to achieve precise dimensions and surface finish. It uses a grinding wheel to remove material from the gear teeth, resulting in high-quality gears with improved accuracy, smoothness, and noise reduction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gear Setters are responsible for the setup and operation of gear hobbing machines. Their key responsibilities include:

1. Machine Setup

Setting up and configuring gear hobbing machines according to specified production requirements.

- Installing and aligning gears, cutters, and other machine components.

- Adjusting machine settings, such as speed, feed rates, and cutting depths.

2. Machine Operation

Operating gear hobbing machines to produce gears with precise dimensions and surface finishes.

- Monitoring machine performance and making necessary adjustments.

- Troubleshooting and resolving any technical issues that arise during operation.

3. Quality Control

Ensuring the quality of gears produced by inspecting and measuring their dimensions and surface finishes.

- Using measuring instruments, such as calipers and micrometers, to verify dimensions and tolerances.

- Inspecting gears for any defects or imperfections.

4. Maintenance

Performing routine maintenance and repairs on gear hobbing machines to ensure optimal performance.

- Lubricating and cleaning machine components.

- Replacing worn or damaged parts.

Interview Tips

To ace an interview for a Gear Setter position, it is crucial to demonstrate your technical skills and knowledge in gear manufacturing, as well as your problem-solving and attention to detail. Here are some tips to help you prepare for the interview:

1. Technical Knowledge

Thoroughly review the key job responsibilities and familiarize yourself with the gear manufacturing process. Research different types of gear hobbing machines and the principles of gear cutting.

- Highlight your experience in setting up and operating gear hobbing machines, including your ability to adjust machine settings and troubleshoot technical issues.

- Emphasize your knowledge of gear measurement and inspection techniques.

2. Problem-Solving and Analytical Skills

Gear Setters often encounter technical challenges during the manufacturing process. Showcase your ability to analyze problems, identify root causes, and develop effective solutions.

- Describe a situation where you successfully resolved a technical issue with a gear hobbing machine.

- Explain your approach to problem-solving and how you ensure accuracy and precision in your work.

3. Attention to Detail

Gear Setters need to be meticulous and pay attention to even the smallest details. Highlight your strong observational skills and your ability to identify and correct errors.

- Provide examples of your attention to detail in previous roles, such as identifying and correcting dimensional deviations or surface imperfections in gears.

- Emphasize your understanding of the importance of accuracy and precision in gear manufacturing.

4. Communication Skills

Effective communication is essential for Gear Setters to work effectively with supervisors, colleagues, and customers. Demonstrate your ability to communicate clearly and concisely, both verbally and in writing.

- Describe a situation where you effectively communicated technical information to a non-technical audience.

- Explain your approach to collaboration and how you contribute to a team environment.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Gear Setter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.