Are you gearing up for an interview for a Gear Sorting and Inspecting Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Gear Sorting and Inspecting Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

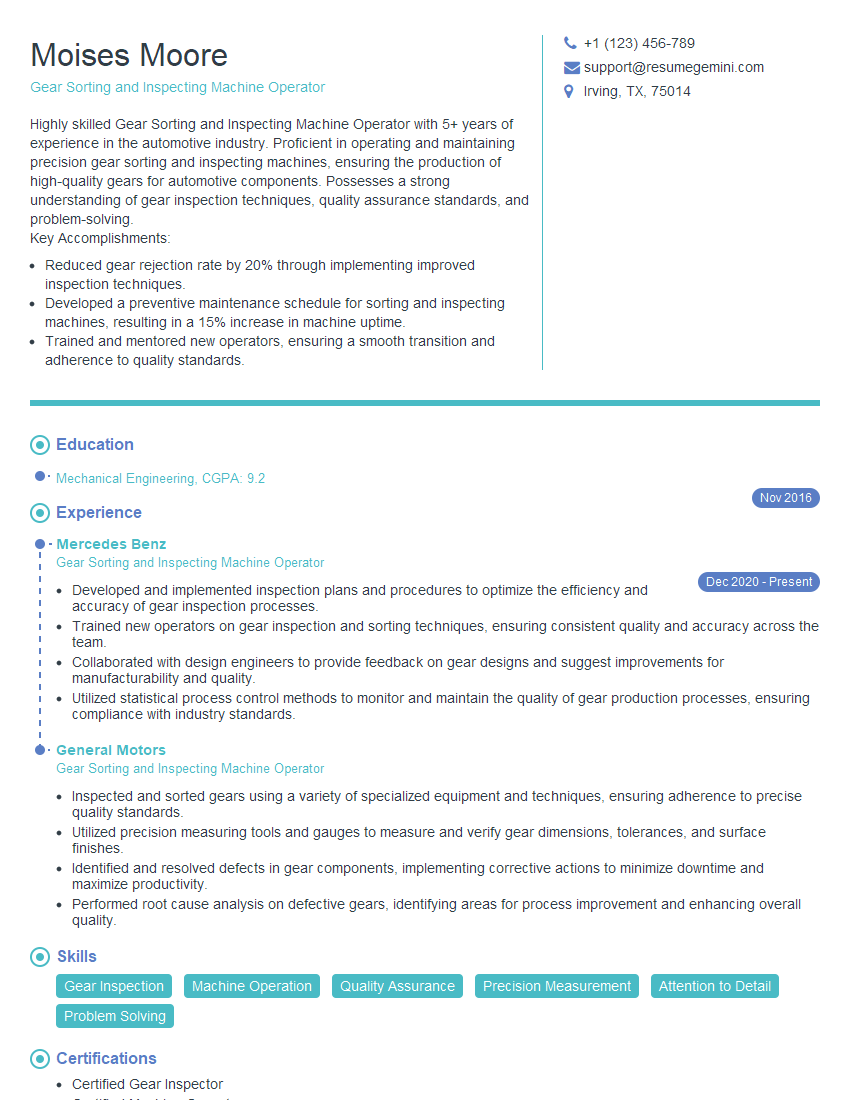

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Sorting and Inspecting Machine Operator

1. What are the primary responsibilities of a Gear Sorting and Inspecting Machine Operator?

The primary responsibilities of a Gear Sorting and Inspecting Machine Operator include:

- Operate gear sorting and inspecting machines to sort and inspect gears for defects.

- Set up and calibrate machines according to specifications.

2. What are the key technical skills required to be successful in this role?

Knowledge of gear manufacturing processes

- Understanding of gear design and specifications.

- Expertise in gear inspection techniques.

Proficiency in operating gear sorting and inspecting machines

- Experience in setting up and calibrating machines.

- Knowledge of machine troubleshooting and maintenance.

3. How do you ensure the accuracy and reliability of your inspections?

I ensure the accuracy and reliability of my inspections by:

- Following established inspection procedures.

- Using calibrated measuring equipment.

- Conducting thorough visual and dimensional inspections.

- Documenting inspection results accurately.

4. What are some common defects that you inspect gears for?

Some common defects that I inspect gears for include:

- Tooth damage (e.g., pitting, wear, breakage)

- Dimensional errors (e.g., out-of-round, excessive backlash)

- Material defects (e.g., cracks, voids, inclusions)

- Surface finish defects (e.g., burrs, scratches, rust)

5. How do you handle gears that fail inspection?

When I identify gears that fail inspection, I:

- Segregate the defective gears from the acceptable ones.

- Document the defects and notify the appropriate personnel.

- Follow established procedures for handling and disposing of defective gears.

6. What is your approach to troubleshooting and resolving machine problems?

My approach to troubleshooting and resolving machine problems includes:

- Identifying the symptoms of the problem.

- Consulting with technical documentation and manuals.

- Inspecting the machine for any visible signs of damage or wear.

- Performing diagnostic tests to isolate the root cause of the problem.

- Implementing appropriate repair or maintenance procedures.

7. How do you stay up-to-date with the latest advancements in gear manufacturing and inspection technology?

I stay up-to-date with the latest advancements in gear manufacturing and inspection technology by:

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Participating in online forums and discussion groups.

- Consulting with experts in the field.

8. What is your understanding of gear tolerances and how do you ensure compliance?

Gear tolerances refer to the allowable variations in the dimensions, shape, and surface finish of gears. To ensure compliance with gear tolerances, I:

- Use calibrated measuring equipment and follow established inspection procedures.

- Compare inspection results to specified tolerances.

- Document any deviations from the specified tolerances.

- Work closely with production personnel to ensure that gears are manufactured within the required tolerances.

9. How do you ensure the safety and accuracy of your work?

I ensure the safety and accuracy of my work by:

- Following established safety protocols.

- Using appropriate personal protective equipment.

- Performing regular equipment maintenance and calibration.

- Documenting inspection results accurately and thoroughly.

- Seeking assistance from supervisors or colleagues when necessary.

10. What motivates you to excel in this role?

I am motivated to excel in this role because I am passionate about quality control and ensuring that gears meet the required specifications. I take pride in my work and am committed to delivering accurate and reliable inspection results. I am also eager to learn and grow in my career, and I believe that this role provides me with an opportunity to develop my skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Sorting and Inspecting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Sorting and Inspecting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gear Sorting and Inspecting Machine Operators are responsible for operating and monitoring machines that sort and inspect gears for quality and dimensional accuracy. They play a crucial role in ensuring the quality and reliability of gears used in various industries.

1. Machine Operation

Operate gear sorting and inspecting machines to separate gears based on specifications such as size, shape, and quality.

- Load gears into the machine and set up parameters.

- Monitor the machine’s operation to ensure smooth functioning.

2. Gear Inspection

Inspect gears for defects, wear, and dimensional accuracy using various measuring tools and instruments.

- Identify and sort gears that meet or exceed quality standards.

- Reject non-conforming gears and document defects.

3. Quality Control

Maintain quality standards and ensure that gears meet customer specifications and industry regulations.

- Calibrate and maintain inspection equipment to ensure accuracy.

- Document inspection results and report any discrepancies.

4. Maintenance and Troubleshooting

Perform basic maintenance and troubleshooting on sorting and inspecting machines.

- Clean and lubricate machines as per schedule.

- Identify minor malfunctions and take corrective actions.

Interview Tips

To ace the interview for the Gear Sorting and Inspecting Machine Operator position, it is essential to prepare thoroughly. Here are some tips to help you make a strong impression:

1. Research the Company

Before the interview, take the time to research the company and the specific industry they operate in. This will give you a better understanding of their business and the role you are applying for.

- Visit the company website, read industry news, and research the company’s products or services.

- Prepare questions that show you have done your research and are interested in the company.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your skills and experience.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Describe your experience with gear sorting and inspecting machines.

3. Highlight Relevant Skills

Emphasize the skills and experience that are most relevant to the job responsibilities. Showcase your proficiency in:

- Operating and maintaining gear sorting and inspecting machines

- Gear inspection techniques and quality control procedures

- Attention to detail, accuracy, and problem-solving abilities

4. Prepare Industry-Specific Questions

Show that you are knowledgeable about the industry by asking questions that demonstrate your understanding of the field. For example:

- What are the latest advancements in gear manufacturing technology?

- How does your company ensure the quality and reliability of its gears?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gear Sorting and Inspecting Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.