Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gelatin Maker, Utility position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

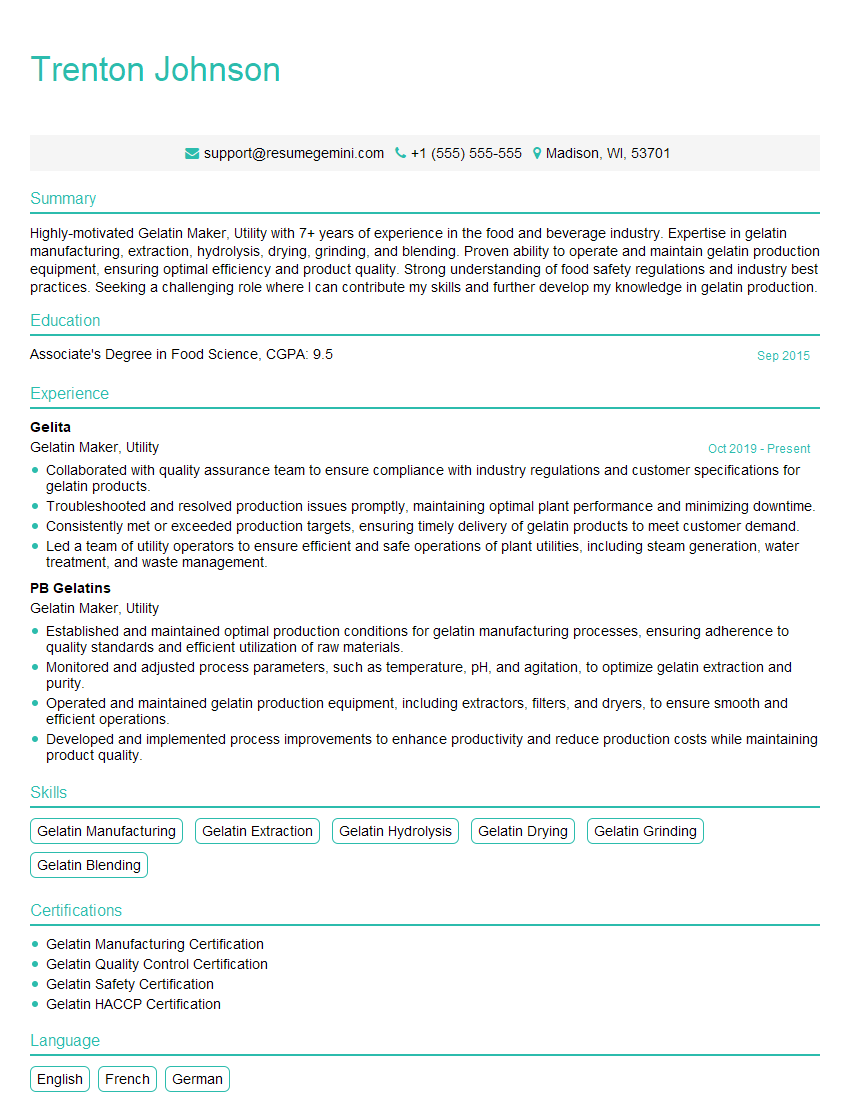

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gelatin Maker, Utility

1. Describe the process of gelatin production from raw materials to finished product.

- Receiving and inspection of raw materials.

- Pretreatment of raw materials (e.g., washing, soaking, cooking).

- Extraction of gelatin (using acid or alkali treatment).

- Purification and filtration of gelatin solution.

- Concentration of gelatin solution.

- Gelatin setting (forming sheets or granules).

- Drying and cooling of gelatin.

- Grinding and packaging of gelatin.

2. What are the critical quality attributes (CQAs) of gelatin and how do you ensure their compliance in production?

Quality control measures

- Raw material inspection and testing.

- Process control and monitoring (e.g., temperature, pH, time).

- In-process testing (e.g., viscosity, gel strength).

- Finished product testing (e.g., water content, bloom strength, clarity).

CQAs and their importance

- Bloom strength: Measures the gel strength and quality of gelatin.

- Viscosity: Affects the flowability and thickening properties of gelatin.

- Clarity: Indicates the purity and absence of contaminants in gelatin.

- Water content: Important for storage stability and functional properties.

3. Explain the different types of gelatin and their applications in the food industry.

- Type A gelatin: Derived from acidic sources (e.g., pork skin), used in confectionery, desserts, and photography.

- Type B gelatin: Derived from alkaline sources (e.g., beef bone), used in food, pharmaceutical, and cosmetic applications.

- Fish gelatin: Derived from fish skin and bones, used in halal and kosher products, and biomedical applications.

- Hydrolyzed gelatin: Enzymatically broken down gelatin, used as a thickening and gelling agent, and in nutritional supplements.

4. Describe the principles of gelatin gelation and the factors affecting the gel strength.

Principles of gelation

- Gelatin forms a gel when its solutions cool and develop a network of intermolecular bonds.

- The gel strength is determined by the molecular weight, concentration, and bloom strength of gelatin.

Factors affecting gel strength

- Gelatin concentration.

- Type and bloom strength of gelatin.

- pH and temperature during gelation.

- Presence of other ingredients (e.g., sugars, salts).

5. What are the common problems encountered in gelatin production and how do you troubleshoot them?

- Problem: Weak gel strength. Possible causes: low gelatin concentration, incorrect bloom strength, improper pH or temperature.

- Problem: Cloudy or hazy gelatin. Possible causes: impurities or contaminants in raw materials or during processing.

- Problem: Gelatin does not set properly. Possible causes: incorrect pH or temperature, presence of inhibitors (e.g., enzymes, tannins).

6. How do you maintain and calibrate the equipment used in gelatin production, such as cookers, filters, and dryers?

- Regular cleaning and maintenance of equipment.

- Calibration of sensors and instruments (e.g., temperature, pH, flow rate).

- Use of standard reference materials and solutions.

- Following manufacturer’s instructions and maintenance schedules.

7. What is your understanding of Good Manufacturing Practices (GMP) and how do you apply them in gelatin production?

- Maintaining a clean and sanitary production environment.

- Control of raw materials and finished products.

- Proper documentation and traceability of production processes.

- Training and supervision of personnel.

8. How do you manage the waste generated during gelatin production?

- Minimizing waste generation through efficient processing techniques.

- Proper disposal of liquid and solid waste according to environmental regulations.

- Exploring waste reduction and recycling opportunities.

9. What are the recent trends and innovations in the gelatin industry and how do you keep yourself updated with them?

- Development of new gelatin types with improved properties.

- Use of alternative raw materials (e.g., plant-based sources).

- Advancements in gelatin processing technologies.

- Attending industry conferences and workshops.

- Subscribing to industry publications and online resources.

10. How do you work effectively in a team environment and handle conflicts or disagreements?

- Active participation and contribution to team discussions.

- Respecting and valuing the opinions of others.

- Collaborating and sharing knowledge with team members.

- Resolving conflicts through open communication and compromise.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gelatin Maker, Utility.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gelatin Maker, Utility‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gelatin Maker, Utilities are responsible for a variety of tasks related to the production of gelatin. Gelatin is a protein derived from collagen and is used in a variety of products, including food, pharmaceuticals, and cosmetics.

1. Gelatin Production

Gelatin Maker, Utilities are responsible for operating the equipment used to produce gelatin. They must ensure that the equipment is running properly and that the gelatin is produced to specifications. They may also be responsible for maintaining the equipment and making repairs.

2. Quality Control

Gelatin Maker, Utilities are responsible for conducting quality control tests on the gelatin. They must ensure that the gelatin meets the required standards for purity and quality.

3. Safety

Gelatin Maker, Utilities must follow all safety regulations and procedures. They must wear appropriate safety gear and operate the equipment safely. They must also be aware of the potential hazards associated with gelatin production.

4. Housekeeping

Gelatin Maker, Utilities are responsible for keeping the work area clean and organized. They must also dispose of waste materials properly.

Interview Tips

To ace the interview, candidates for Gelatin Maker, Utility positions should be prepared to discuss their experience in the following areas:

1. Gelatin Production

Candidates should be familiar with the process of gelatin production and the equipment used in the process. They should also be able to discuss the quality control procedures used to ensure that the gelatin meets specifications.

- Example: “In my previous role, I was responsible for operating the gelatin production equipment and conducting quality control tests. I ensured that the gelatin met the required standards for purity and quality.”

2. Safety

Candidates should be familiar with the safety regulations and procedures related to gelatin production. They should also be able to discuss the potential hazards associated with gelatin production and how to prevent them.

- Example: “In my previous role, I was responsible for following all safety regulations and procedures. I wore appropriate safety gear and operated the equipment safely. I was also aware of the potential hazards associated with gelatin production and how to prevent them.”

3. Communication

Candidates should be able to communicate effectively with other members of the team, as well as with customers and suppliers. They should also be able to write clear and concise reports.

- Example: “In my previous role, I was responsible for communicating with other members of the team, as well as with customers and suppliers. I was also responsible for writing clear and concise reports.”

4. Troubleshooting

Candidates should be able to troubleshoot problems with the gelatin production equipment and process. They should also be able to identify and correct problems with the gelatin itself.

- Example: “In my previous role, I was responsible for troubleshooting problems with the gelatin production equipment and process. I was also responsible for identifying and correcting problems with the gelatin itself.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gelatin Maker, Utility interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!