Are you gearing up for a career in General Foundry Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for General Foundry Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

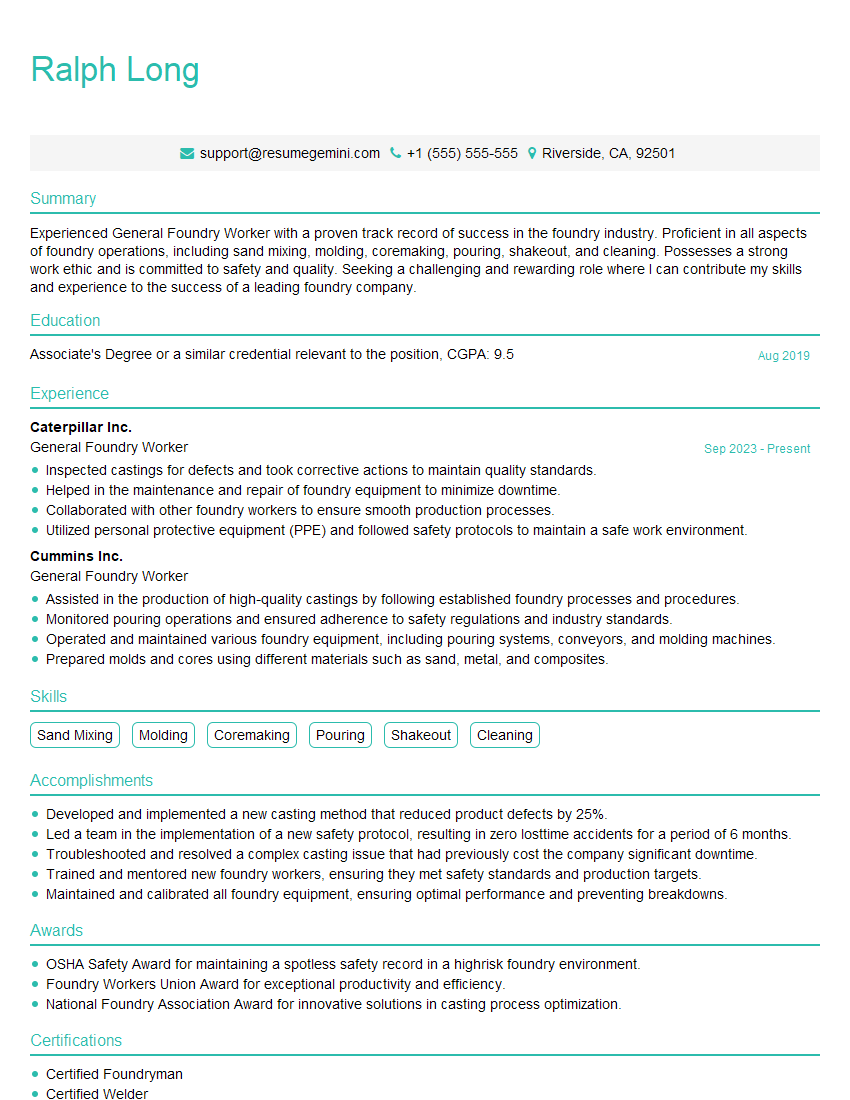

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For General Foundry Worker

1. Describe the process of sand casting, including pattern preparation, mold making, and pouring techniques?

– Pattern preparation involves creating a pattern that replicates the desired shape of the casting. – Mold making includes creating a mold cavity based on the pattern, using materials like sand, and preparing it for pouring. – Pouring techniques involve melting the molten metal and carefully pouring it into the mold to form the casting.

2. Explain the different types of molding processes used in foundries, such as green sand molding, shell molding, and investment casting?

Green sand molding

- Uses moist sand mixed with binders to form the mold.

- Suitable for large and medium-sized castings.

Shell molding

- Uses a thin, resin-bonded sand shell as the mold.

- Provides higher dimensional accuracy and surface finish.

Investment casting

- Uses a wax pattern coated with a refractory material.

- Suitable for intricate and high-precision castings.

3. How do you interpret blueprints and technical drawings for foundry operations?

- Understanding symbols, dimensions, and tolerances.

- Visualizing the 3D object represented by the drawing.

- Identifying critical dimensions and features.

4. Describe the safety procedures and equipment used in a foundry, including personal protective equipment (PPE) and proper handling of molten metal?

- Wearing appropriate PPE such as gloves, apron, safety glasses, and respirator.

- Following established safety protocols for handling molten metal, such as using tongs and avoiding contact with bare skin.

- Maintaining a clean and organized work area.

5. How do you maintain and troubleshoot equipment commonly used in foundries, such as melting furnaces and molding machines?

- Performing regular inspections and preventive maintenance.

- Identifying and diagnosing equipment issues.

- Making necessary adjustments or repairs.

6. Explain the different types of defects that can occur in castings and describe the methods used to prevent or correct them?

- Shrinkage porosity: Occurs when the molten metal solidifies and contracts, creating voids. Prevented by proper mold design, feeding systems, and cooling rates.

- Cold shuts: Forms when two streams of molten metal fail to fuse together. Prevented by pouring at the correct temperature and avoiding turbulence.

- Gas porosity: Caused by trapped gases in the molten metal. Prevented by using degassing techniques.

7. What is the importance of quality control in foundry operations?

- Ensures that castings meet customer specifications.

- Minimizes casting defects and improves yield.

- Maintains a high level of customer satisfaction.

8. Describe the different methods used for testing and inspecting castings, such as visual inspection, dimensional measurement, and non-destructive testing?

Visual inspection

- Checking for surface defects, cracks, or other irregularities.

Dimensional measurement

- Verifying that castings meet specified dimensions and tolerances.

Non-destructive testing

- Using techniques such as radiography, ultrasonic testing, or magnetic particle inspection to detect internal defects.

9. What is your experience with working with different types of metals and alloys used in foundries?

- Knowledge of properties and characteristics of various metals.

- Understanding of melting points, solidification temperatures, and heat treatment processes.

10. Describe your ability to work as part of a team and contribute to a foundry production environment?

- Strong communication and collaboration skills.

- Ability to handle physical demands of the job.

- Willingness to learn and adapt to new challenges.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for General Foundry Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the General Foundry Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A General Foundry Worker is responsible for various tasks in a foundry, supporting the production of metal castings. Their key responsibilities include:

1. Mold Making and Preparation

Preparing molds by assembling pattern equipment, ramming molding sand and creating parting lines.

2. Molten Metal Handling

Handling molten metal, including pouring and skimming furnaces, controlling temperature and ensuring safety.

3. Casting Removal and Cleaning

Removing castings from molds, cleaning them using sandblasters, grinders and other equipment.

4. Equipment and Tool Maintenance

Maintaining and repairing foundry equipment and tools, ensuring they are in good working condition.

5. Safety and Quality Assurance

Following safety protocols, using appropriate personal protective equipment and adhering to quality standards.

Interview Tips

To ace the interview for a General Foundry Worker position, candidates should focus on:

1. Research and Preparation

Research the company, the industry, and the specific role. Understand the key responsibilities and challenges.

2. Highlight Relevant Experience

Emphasize previous experience in a foundry setting, including specific skills in mold making, metal handling, and equipment maintenance.

3. Safety Awareness

Demonstrate a strong understanding of foundry safety protocols, including the proper use of personal protective equipment.

4. Problem-Solving Abilities

Highlight problem-solving skills, such as identifying and resolving issues with equipment or processes.

5. Physical Endurance

Convey your physical endurance and ability to work in a demanding environment, including exposure to heat, noise, and heavy lifting.

6. Teamwork and Communication

Emphasize your teamwork abilities and ability to communicate effectively with colleagues and supervisors.

7. Example Outline

Prepare concise and specific examples of your experience that demonstrate your skills and abilities.

8. Confidence and Enthusiasm

Project confidence and enthusiasm for the role, showing that you are eager to contribute to the foundry’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the General Foundry Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.