Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted General Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

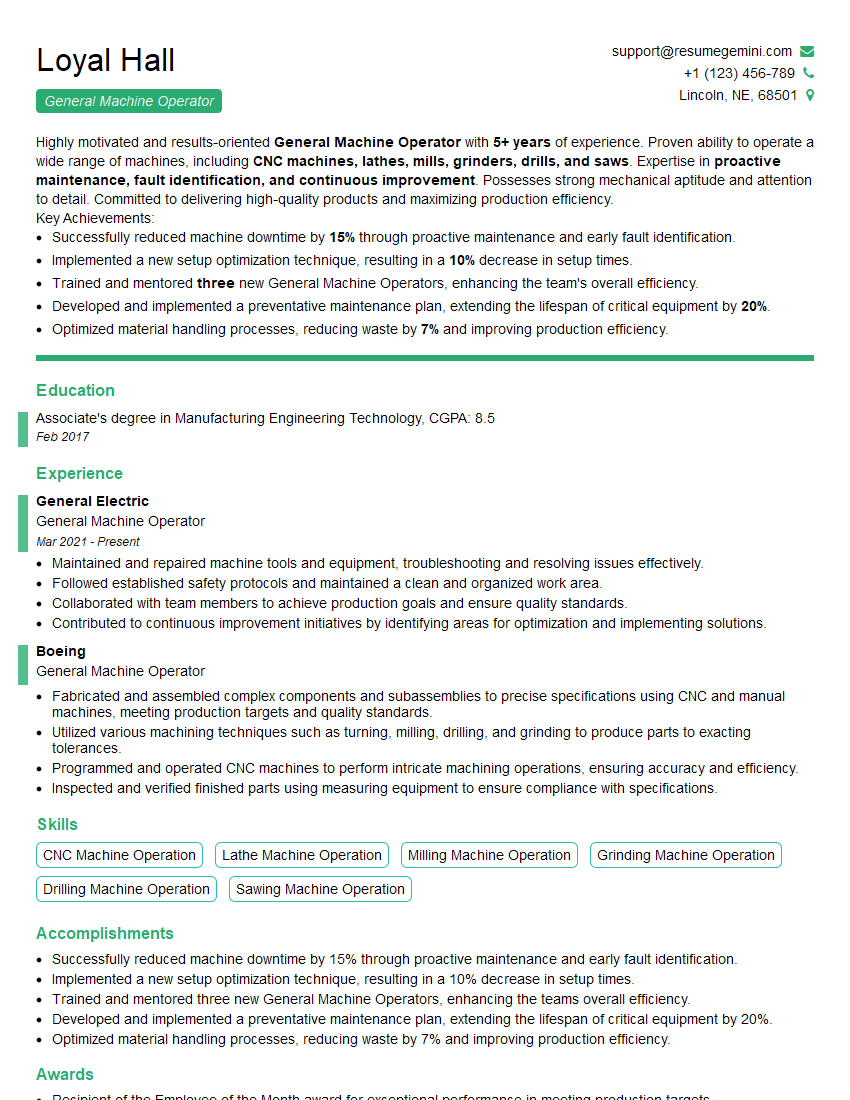

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For General Machine Operator

1. Explain the process of setting up a machine for a new job?

When setting up a machine for a new job, I follow a systematic process to ensure accuracy and efficiency:

- Review the Job Order: I begin by thoroughly reviewing the job order to understand the specific requirements and specifications.

- Inspect the Machine and Tooling: I inspect the machine and tooling to make sure they are in good working order and meet the job’s needs.

- Select and Mount the Workpiece: I carefully select the workpiece and mount it securely on the machine, ensuring proper alignment and clamping.

- Set Machine Parameters: I input the necessary parameters into the machine’s controller, including cutting speeds, feed rates, and depths of cut.

- Calibrate and Test: I perform calibration and test runs to ensure the machine is functioning correctly and the workpiece is being processed as intended.

2. Describe the types of cutting tools used in general machine operation?

Cutting Tools:

- Single-Point Cutting Tools: These tools, such as lathe bits and milling cutters, have a single cutting edge that removes material from the workpiece.

- Multi-Point Cutting Tools: These tools, such as drills, taps, and reamers, have multiple cutting edges that work together to create holes or threads.

Tool Materials:

- High-Speed Steel (HSS): HSS tools are commonly used for general-purpose cutting operations.

- Carbide: Carbide tools offer superior wear resistance and can handle harder materials.

- Ceramic: Ceramic tools are used for high-speed, precision cutting.

3. Explain the importance of workholding devices in machine operation?

Workholding devices are essential for securing workpieces during machining operations. They:

- Maintain Accuracy: They ensure the workpiece is held securely, preventing movement or vibration that can affect the accuracy of the finished product.

- Improve Safety: By securely holding the workpiece, workholding devices reduce the risk of accidents and injuries.

- Increase Productivity: They allow for continuous machining operations without the need for manual adjustments or re-clamping, which saves time and improves efficiency.

4. Discuss the different types of measuring instruments used in general machine operation?

- Calipers: Used for measuring external and internal dimensions, such as diameters and lengths.

- Micrometers: Used for precise measurements of small dimensions, such as thickness and tolerances.

- Dial Indicators: Used for measuring small displacements and deviations from a reference point.

- Gauges: Used for checking specific dimensions or tolerances, such as thread gauges and ring gauges.

- Coordinate Measuring Machines (CMMs): Used for high-precision, three-dimensional measurements.

5. What are the safety precautions to be taken when operating a general machine?

- Wear Proper PPE: Always wear safety glasses, gloves, and appropriate clothing to protect yourself from flying debris, sparks, and chemicals.

- Secure Loose Clothing: Ensure loose clothing, hair, or jewelry cannot get caught in moving parts.

- Inspect Machine Regularly: Check the machine before each use for any damage or loose parts.

- Use Proper Tools: Use the correct tools and attachments for the specific job, and ensure they are in good condition.

- Clear Away Obstructions: Keep the work area clear of obstructions and debris to prevent accidents.

- Follow Operating Instructions: Carefully follow the operating instructions for the machine to avoid improper use.

6. Describe the maintenance procedures required for general machines?

Regular maintenance is crucial to ensure the longevity and optimal performance of general machines:

- Lubrication: Regularly lubricate moving parts to reduce friction and wear.

- Cleaning: Clean the machine regularly to remove debris, chips, and coolant.

- Tightening: Check and tighten bolts, screws, and nuts to prevent looseness.

- Inspecting: Regularly inspect the machine for any damage, leaks, or wear and tear.

- Calibrating: Calibrate measuring instruments and sensors to ensure accuracy.

7. Explain the different types of CNC (Computer Numerical Control) machines?

- CNC Mills: Used for milling, drilling, and contouring operations.

- CNC Lathes: Used for turning, boring, and facing operations.

- CNC Routers: Used for cutting and shaping materials such as wood, plastic, and composites.

- CNC Plasma Cutters: Used for cutting metal using a plasma torch.

- CNC Waterjet Cutters: Used for precision cutting using a high-pressure water jet.

8. What are the advantages of using CNC machines?

- Accuracy: CNC machines provide high precision and accuracy, reducing the need for manual adjustments.

- Repeatability: They can produce consistent, high-quality parts with minimal variation.

- Efficiency: Automating machining operations improves productivity and efficiency.

- Complex Shapes: CNC machines can produce complex shapes and geometries that are difficult or impossible to achieve manually.

- Reduced Labor Costs: CNC machines require less human intervention, potentially reducing labor costs.

9. Discuss the factors to consider when selecting cutting tools for a specific job?

- Material of the Workpiece: Consider the hardness, toughness, and machinability of the material.

- Type of Machining Operation: Different tools are required for operations such as turning, milling, or drilling.

- Cutting Speed and Feed Rate: Choose tools that can handle the desired cutting parameters.

- Tool Geometry: The shape and geometry of the tool affect the surface finish and accuracy of the cut.

- Tool Life: Consider the expected tool life to minimize downtime and replacement costs.

10. Describe the process of troubleshooting common machine problems?

- Identify the Problem: Clearly define the issue by observing symptoms and gathering information.

- Review the Manual: Consult the machine’s manual or online resources for troubleshooting guidelines.

- Check for Obvious Causes: Inspect for loose connections, broken wires, or worn parts.

- Test Components: Use diagnostic tools or techniques to test individual components, such as sensors, actuators, or controllers.

- Replace or Repair: Once the faulty component is identified, replace or repair it as necessary.

- Retest and Monitor: After resolving the issue, retest the machine and monitor its performance to ensure the problem is fully addressed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for General Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the General Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A General Machine Operator, also known as Machinist Assistant, plays a vital role in the production process, assisting skilled machinists in operating and monitoring various machines. Their primary responsibilities include:

1. Machine Operation

Operate machines such as lathes, drills, mills, and grinders as per instructions from the machinist.

- Set up and adjust machines to meet production specifications.

- Monitor machine operation and make necessary adjustments to ensure accuracy and efficiency.

2. Material Handling

Handle and transport materials, including raw materials, workpieces, and finished products.

- Load and unload materials from machines.

- Move materials within the work area using forklifts or other equipment.

3. Quality Control

Assist in quality control measures by inspecting workpieces for accuracy and conformance to specifications.

- Use measuring tools and gauges to check dimensions and tolerances.

- Identify and report any defects or discrepancies to the machinist.

4. Maintenance and Cleaning

Perform basic maintenance and cleaning tasks to ensure the smooth operation of machines and the surrounding work area.

- Lubricate machines and change tools as needed.

- Clean machines and work surfaces to maintain a safe and organized work environment.

Interview Tips

To ace an interview for the role of General Machine Operator, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry. Research the specific role and its responsibilities to demonstrate your interest and understanding.

- Visit the company’s website and social media pages.

- Look for news articles and industry reports about the company.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in operating and handling machinery. Showcase your knowledge of quality control procedures and your ability to work in a fast-paced environment.

- Quantify your accomplishments whenever possible.

- Be prepared to discuss specific examples of your work.

3. Demonstrate Problem-Solving Abilities

Interviewers often seek candidates who can solve problems independently. Provide examples of how you have identified and resolved issues in your previous roles.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on the results you achieved and the skills you used.

4. Prepare Questions

Asking thoughtful questions at the end of the interview shows that you are interested and engaged. Prepare questions that demonstrate your knowledge of the industry and the company.

- Ask about the company’s growth plans.

- Inquire about opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the General Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.