Are you gearing up for an interview for a Ginning Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Ginning Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

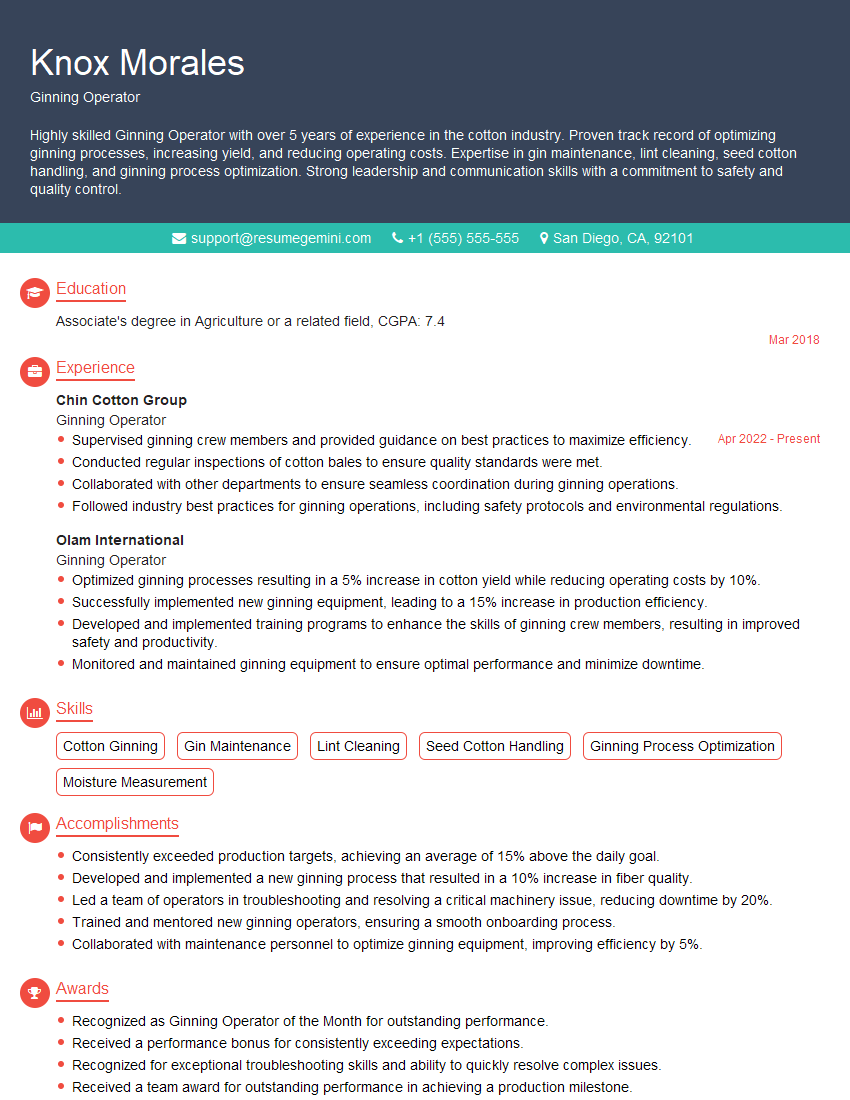

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ginning Operator

1. Explain the process of ginning cotton?

Ginning is the process of separating cotton fibers from the cottonseed. Here’s the step-by-step process:

- Pre-cleaning: Removing impurities like leaves, sticks, and dirt from the seed cotton.

- Ginning: Using a gin stand to separate the fibers from the seeds. The fibers pass through saws or rollers, while the seeds are ejected.

- Lint cleaning: Removing remaining impurities from the ginned fibers using a lint cleaner machine.

- Baling: Compressing the cleaned fibers into bales for storage and transportation.

2. What are the different types of ginning machines and their features?

Roller Gin

- Uses rotating rollers to separate fibers from seeds.

- Suitable for long-staple cotton.

- Produces high-quality fibers.

Saw Gin

- Uses circular saws with teeth to detach fibers.

- Faster and more efficient than roller gins.

- May damage short-staple cotton.

3. Describe the factors that affect the efficiency of a ginning operation?

Efficiency is influenced by several factors, including:

- Ginning machinery: Type, condition, and maintenance of the gin.

- Cotton quality: Fiber length, maturity, and moisture content.

- Operating conditions: Gin speed, temperature, and humidity.

- Operator skills: Experience and knowledge of the operator.

- Ginning capacity: Size and capabilities of the ginning plant.

4. How do you troubleshoot common problems that occur during ginning?

Common problems include:

- Plugged gin stands: Check for foreign objects, adjust gin speed, or clean the saws.

- Poor fiber quality: Adjust gin settings, optimize bale density, or blend different cotton grades.

- Seed damage: Calibrate gin saws, check seed roller gap, or reduce gin speed.

- Low ginning efficiency: Inspect machinery, check operating conditions, or train operators.

5. What maintenance procedures are essential for a ginning operation?

- Regular cleaning: Remove dust, debris, and fiber accumulations.

- Lubrication: Keep all moving parts well-lubricated.

- Inspections: Check for wear and tear, loose bolts, and damaged parts.

- Calibration: Ensure accuracy of gin settings, such as saw speed and roller gap.

- Preventive maintenance: Schedule proactive maintenance tasks to prevent breakdowns.

6. How do you ensure the quality of ginned cotton fibers?

- Fiber testing: Perform tests to assess fiber length, strength, and maturity.

- Visual inspection: Examine fibers for color, cleanliness, and uniformity.

- Bale grading: Classify bales based on quality standards, such as fiber grade and staple length.

- Customer feedback: Monitor customer feedback to identify any quality concerns.

7. What safety precautions should be taken during a ginning operation?

- Wear proper PPE: Earplugs, safety glasses, gloves, and cotton masks.

- Follow lockout procedures: Lock out machinery before performing maintenance.

- Avoid loose clothing: Loose clothing can get caught in machinery.

- Be aware of moving machinery: Keep a safe distance and stay alert.

- Train operators: Provide comprehensive safety training to all operators.

8. How do you stay updated with the latest advances in ginning technology?

- Attend industry events: Participate in conferences, workshops, and trade shows.

- Read industry publications: Stay informed through journals and online resources.

- Network with other ginning professionals: Exchange knowledge and best practices with peers.

- Seek training opportunities: Explore manufacturer-provided training or university courses.

9. What is your experience in managing a team of ginning operators?

In my previous role as a Ginning Supervisor, I led a team of 10 ginning operators. I effectively communicated instructions, delegated tasks, monitored performance, and provided guidance and training to ensure efficient and safe operations.

10. How do you handle challenges or unexpected situations that arise during ginning?

When challenges arise, I remain calm and assess the situation thoroughly. I consult with my team and experts to gather diverse perspectives. Together, we develop and implement solutions that minimize disruptions and maintain operational efficiency. I effectively communicate updates and adjustments to ensure a coordinated response.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ginning Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ginning Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Ginning Operator is responsible for the efficient operation and maintenance of a ginning machine, which separates cotton fibers from the seeds. Their primary duties include:

1. Machine Operation

Operate and monitor the ginning machine to extract cotton fibers from cotton bolls.

- Adjust machine settings to optimize fiber quality and minimize waste.

- Monitor machine performance and identify any potential problems.

2. Quality Control

Ensure the quality of the ginned fibers by monitoring and controlling the ginning process.

- Inspect ginned fibers for defects and impurities.

- Make adjustments to the ginning process to improve fiber quality.

3. Maintenance and Repair

Perform routine maintenance and repairs on the ginning machine and associated equipment.

- Lubricate and adjust machine components.

- Replace worn or damaged parts.

4. Health and Safety

Adhere to all health and safety regulations and procedures related to ginning operations.

- Wear appropriate protective gear.

- Follow established safety protocols.

Interview Tips

To prepare for your Ginning Operator interview, consider the following tips:

1. Research the Company and Industry

Learn about the ginning company you are applying to and the industry as a whole. This will demonstrate your interest and enthusiasm for the role.

- Visit the company website to learn about their operations and values.

- Read industry publications and articles to stay up-to-date on trends.

2. Highlight Relevant Experience

Emphasize your experience in operating and maintaining ginning machines. Quantify your accomplishments whenever possible.

- Describe specific instances where you improved fiber quality or efficiency.

- Mention any training or certifications you have related to ginning operations.

3. Demonstrate Safety Awareness

Ginning operations involve potential hazards. Show the interviewer that you are aware of these hazards and have a strong commitment to safety.

- Discuss your knowledge of industry safety regulations and protocols.

- Share examples of how you have ensured safety in previous roles.

4. Practice Your Interview Skills

Practice answering common interview questions. This will help you feel more confident and prepared during the actual interview.

- Prepare answers to questions about your experience, skills, and qualifications.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ginning Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!