Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Glass Bulb Machine Adjuster interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Glass Bulb Machine Adjuster so you can tailor your answers to impress potential employers.

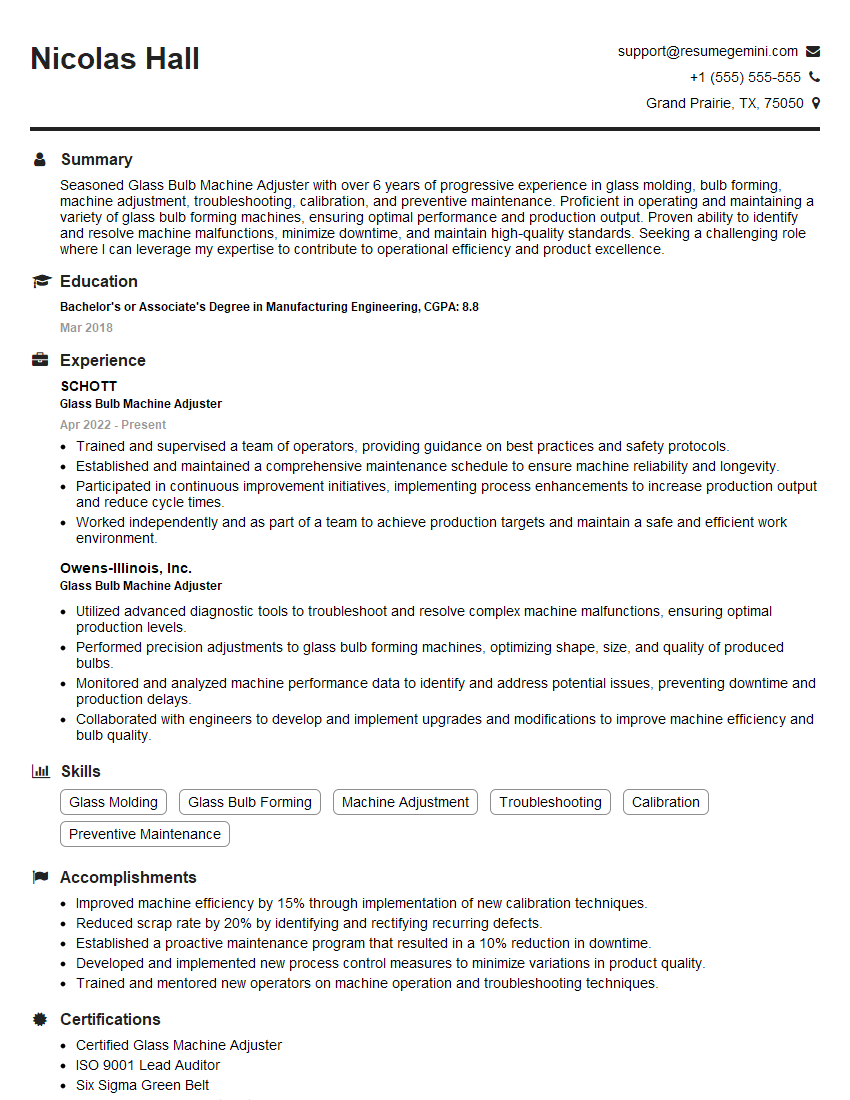

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Bulb Machine Adjuster

1. What are the key responsibilities of a Glass Bulb Machine Adjuster?

- Adjusting and calibrating glass bulb machines to ensure accurate and efficient production.

- Inspecting and maintaining machine components, including burners, moulds, and feeding mechanisms.

- Monitoring production processes and making necessary adjustments to optimize machine performance and product quality.

- Troubleshooting and resolving machine breakdowns to minimize downtime and maintain production efficiency.

- Collaborating with engineers and maintenance teams to implement improvements and upgrades to machine systems.

2. Describe the different types of glass bulb machines you have experience with.

Types of Machines:

- Rotary Blow Machines

- Press and Blow Machines

- Continuous Day Tank Machines

Specific Models:

- IS Machines

- Lynch Machines

- Heye Machines

3. What are the common adjustments you make to calibrate a glass bulb machine?

- Adjusting feeder timing and pressure to ensure proper glass flow.

- Calibrating flame settings to achieve optimal glass temperature and forming.

- Setting mould temperature and cooling rates to control bulb dimensions and shape.

- Monitoring and adjusting machine cycle times to optimize production efficiency.

- Balancing machine components to reduce vibrations and improve product quality.

4. How do you troubleshoot and resolve mechanical breakdowns on glass bulb machines?

- Identifying the source of the breakdown through visual inspection, monitoring sensors, and reviewing machine logs.

- Using troubleshooting manuals and diagnostic tools to isolate the affected component.

- Repairing or replacing faulty components, such as burners, valves, or electrical connections.

- Checking machine alignments, calibrations, and adjustments to ensure proper operation.

- Communicating with maintenance teams for support on complex repairs or equipment upgrades.

5. What are the safety precautions you take when working on glass bulb machines?

- Wearing appropriate personal protective equipment (PPE), including safety glasses, gloves, and protective clothing.

- Following lock-out/tag-out procedures to prevent accidental machine start-ups.

- Handling glass components with care to avoid cuts or burns.

- Monitoring machine temperatures and ventilation systems to ensure a safe work environment.

- Reporting any potential hazards or safety concerns to supervisors and colleagues.

6. How do you stay up-to-date on the latest technologies and best practices in glass bulb machine adjustment?

- Attending industry conferences and workshops

- Reading technical journals and publications

- Consulting with manufacturers and equipment suppliers

- Participating in online forums and discussions

- Seeking feedback and sharing knowledge with peers

7. What are the challenges you have faced as a Glass Bulb Machine Adjuster and how did you overcome them?

Challenge: Machine Breakdowns

- Improved troubleshooting skills

- Developed proactive maintenance plans

Challenge: Product Quality Issues

- Enhanced inspection processes

- Collaborated with engineers to optimize machine settings

8. How do you work effectively in a team environment with other technicians and operators?

- Communicating clearly and sharing information

- Coordinating tasks and supporting colleagues

- Resolving conflicts and maintaining a positive work atmosphere

- Training and mentoring junior team members

- Collaborating on process improvements and efficiency initiatives

9. Describe a time when you had to make a critical decision under pressure.

Highlight your decision-making process, problem-solving skills, and ability to handle stressful situations.

10. How do you measure your success as a Glass Bulb Machine Adjuster?

- Machine uptime and production efficiency

- Product quality and customer satisfaction

- Contribution to continuous improvement initiatives

- Team performance and collaboration

- Personal growth and professional development

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Bulb Machine Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Bulb Machine Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glass Bulb Machine Adjusters are experts in the manufacturing of glass bulbs, specifically in adjusting and maintaining the machines that produce these bulbs.

1. Machine Adjustment and Operation

Adjusters are responsible for setting up and operating glass bulb making machines, ensuring they meet the required specifications and standards.

- Calibrate and fine-tune machine settings to produce bulbs with precise dimensions and shapes.

- Monitor machine performance and make necessary adjustments to optimize production efficiency.

2. Troubleshooting and Maintenance

When machines encounter technical issues, adjusters identify and resolve them promptly to minimize downtime.

- Perform regular maintenance and inspections to ensure machines operate smoothly and efficiently.

- Diagnose and repair mechanical and electrical faults, replacing or fixing faulty components.

3. Quality Control

Adjusters play a crucial role in ensuring the quality of the glass bulbs produced.

- Inspect bulbs for defects and deviations from specifications.

- Maintain and calibrate inspection equipment, such as gauges and measuring devices.

4. Process Improvement and Optimization

Adjusters continually seek ways to enhance the manufacturing process and increase productivity.

- Analyze production data and identify areas for improvement.

- Implement process modifications to reduce waste and increase production yield.

Interview Tips

To ace the interview for a Glass Bulb Machine Adjuster position, it is essential to demonstrate a strong understanding of the job responsibilities and possess the necessary skills and experience.

1. Research the Company and Industry

Before the interview, thoroughly research the company and the glass manufacturing industry to gain insights into their operations and challenges.

- Visit the company website and read about their products, services, and mission.

- Explore industry publications and news articles to stay informed about the latest advancements and trends.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in adjusting and operating glass bulb making machines, as well as your troubleshooting and maintenance expertise.

- Provide specific examples of how you have resolved complex technical issues and improved machine performance.

- Quantify your accomplishments by providing metrics such as reduced downtime or increased production yield.

3. Demonstrate Quality Focus

Glass bulb manufacturing requires meticulous attention to detail and a commitment to quality.

- Explain your processes for ensuring the accuracy and consistency of bulb dimensions and shapes.

- Describe any quality control measures you have implemented or improved upon.

4. Show Your Commitment to Continuous Improvement

Adjusters should be proactive in seeking ways to enhance the manufacturing process and increase productivity.

- Discuss your experience in analyzing production data and identifying areas for improvement.

- Provide examples of process modifications you have implemented that have led to reduced costs or increased efficiency.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Glass Bulb Machine Adjuster, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Glass Bulb Machine Adjuster positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.