Feeling lost in a sea of interview questions? Landed that dream interview for Glass Bulb Silverer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Glass Bulb Silverer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

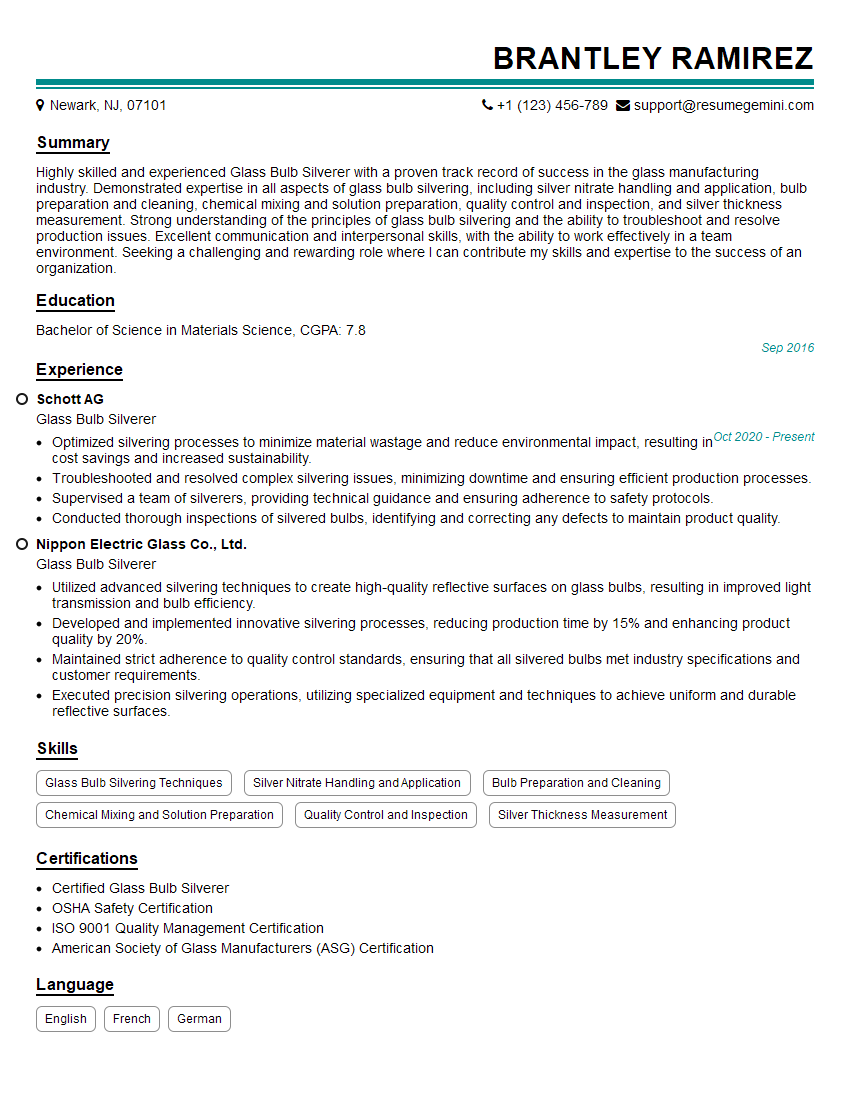

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Bulb Silverer

1. What are the different types of silvering solutions used in glass bulb silvering?

There are two main types of silvering solutions used in glass bulb silvering: ammoniacal silver nitrate and Rochelle silver.

- Ammoniacal silver nitrate is a solution of silver nitrate, ammonium hydroxide, and water. It is the most common type of silvering solution used in glass bulb silvering.

- Rochelle silver is a solution of silver nitrate, sodium potassium tartrate, and water. It is less common than ammoniacal silver nitrate, but it produces a more durable silver coating.

2. What are the steps involved in the glass bulb silvering process?

Cleaning and Preparation

- The first step in the glass bulb silvering process is to clean the glass bulb. This can be done by washing the bulb with a mild detergent and water, or by using a commercial glass cleaner.

- Once the bulb is clean, it is rinsed with water and dried.

Sensitization

- The next step is to sensitize the bulb. This is done by coating the bulb with a solution of stannous chloride. The stannous chloride will react with the silver nitrate in the silvering solution to form silver ions.

- The bulb is then rinsed with water and dried.

Silvering

- The final step is to silver the bulb. This is done by coating the bulb with a silvering solution. The silver ions in the solution will be reduced to silver metal, which will form a coating on the bulb.

- The bulb is then rinsed with water and dried.

3. What are the safety precautions that must be taken when working with silvering solutions?

Silvering solutions are corrosive and can cause skin irritation and burns. It is important to take the following safety precautions when working with silvering solutions:

- Wear gloves and eye protection.

- Avoid contact with skin and eyes.

- Do not ingest silvering solutions.

- Work in a well-ventilated area.

- Dispose of silvering solutions properly.

4. What are the common defects that can occur in the glass bulb silvering process?

There are a number of common defects that can occur in the glass bulb silvering process. These defects can be caused by a variety of factors, including:

- Improper cleaning and preparation of the glass bulb

- Incorrect sensitization of the bulb

- Improper silvering of the bulb

- Contamination of the silvering solution

5. How can these defects be prevented?

There are a number of ways to prevent the common defects that can occur in the glass bulb silvering process. These include:

- Properly cleaning and preparing the glass bulb

- Correctly sensitizing the bulb

- Properly silvering the bulb

- Avoiding contamination of the silvering solution

6. What are the different types of glass bulbs used in lighting?

There are a variety of different types of glass bulbs used in lighting. These include:

- Incandescent bulbs

- Fluorescent bulbs

- LED bulbs

- Halogen bulbs

- High-intensity discharge (HID) bulbs

7. What are the advantages and disadvantages of each type of glass bulb?

Each type of glass bulb has its own advantages and disadvantages. Incandescent bulbs are the most common type of light bulb, but they are also the least efficient. Fluorescent bulbs are more efficient than incandescent bulbs, but they can produce a flickering light. LED bulbs are the most efficient type of light bulb, and they also produce a very long lifespan. Halogen bulbs are brighter than incandescent bulbs, but they also use more energy. HID bulbs are the brightest type of light bulb, but they also use the most energy.

8. How can I determine the right type of glass bulb for my application?

The best way to determine the right type of glass bulb for your application is to consider the following factors:

- The amount of light you need

- The color of light you want

- The lifespan of the light bulb

- The energy efficiency of the light bulb

- The cost of the light bulb

9. What are the latest trends in glass bulb silvering?

The latest trends in glass bulb silvering include the use of new materials and new technologies to create more efficient and durable silver coatings. These new materials and technologies include:

- The use of nano-sized silver particles

- The use of sol-gel technology

- The use of plasma-enhanced chemical vapor deposition (PECVD)

10. What are the future prospects for the glass bulb silvering industry?

The future prospects for the glass bulb silvering industry are positive. The demand for glass bulbs is expected to increase in the coming years, as more and more people switch to energy-efficient lighting. This increased demand will lead to increased opportunities for glass bulb silverers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Bulb Silverer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Bulb Silverer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Glass Bulb Silverer, you play a crucial role in the production of glass bulbs used in a variety of industries, including lighting, decoration, and medical applications. Here are your key job responsibilities:

1. Bulb Preparation

You prepare glass bulbs for silvering by cleaning, degreasing, and treating them to ensure a proper adhesion surface for silver.

- Clean and degrease glass bulbs using appropriate solvents and detergents.

- Apply chemical treatments to the surface of the bulbs to promote silver adhesion.

- Inspect bulbs for any defects or imperfections that may affect silvering.

2. Silver Deposition

You deposit a thin layer of silver onto the prepared bulbs using various techniques, such as chemical reduction or vacuum evaporation.

- Prepare silver nitrate solutions or use pre-mixed solutions for chemical reduction.

- Immerse bulbs in the silver solution or place them in a vacuum chamber for evaporation.

- Control temperature, solution composition, and other parameters to achieve the desired silver thickness and adhesion.

3. Drying and Curing

You ensure that the silvered bulbs are thoroughly dried and cured to improve their durability and performance.

- Remove excess moisture from the bulbs after silver deposition.

- Heat treat the bulbs to cure the silver layer and enhance its adhesion.

- Inspect the finished bulbs for any defects or imperfections.

4. Quality Control

You maintain high-quality standards by performing regular inspections and tests on the silvered bulbs.

- Conduct adhesion tests to ensure the silver layer is strongly bonded to the glass surface.

- Measure the thickness and uniformity of the silver layer using specialized equipment.

- Document and report any quality issues or areas for improvement.

Interview Preparation Tips

To ace your Glass Bulb Silverer interview, consider these preparation tips:

1. Research the Company and Industry

Thoroughly research the company you’re applying to, understanding their products, services, and industry standing. Demonstrate your knowledge and interest during the interview.

2. Practice Describing Your Skills

Highlight your relevant skills and experience, such as silver deposition techniques, quality control procedures, and any specialized knowledge in glass manufacturing. Prepare specific examples to showcase your abilities.

3. Prepare for Industry-Specific Questions

Expect questions related to glass bulb manufacturing processes, silver deposition methods, and quality control standards. Review industry publications and articles to stay updated on the latest advancements.

4. Emphasize Attention to Detail

Glass Bulb Silverers require meticulous attention to detail. Emphasize your precision, accuracy, and ability to follow instructions carefully. Provide examples of your ability to identify and address potential quality issues.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Glass Bulb Silverer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.