Are you gearing up for an interview for a Glass Cutting Machine Feeder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Glass Cutting Machine Feeder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

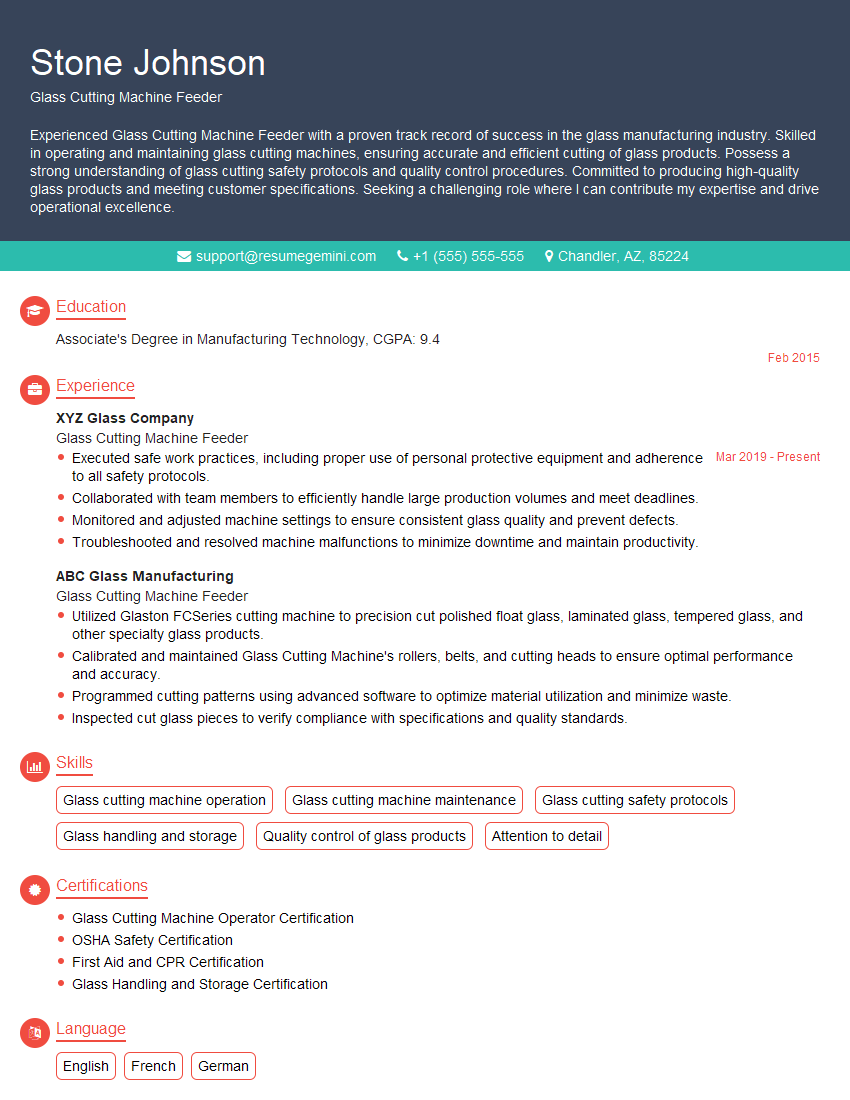

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Cutting Machine Feeder

1. Describe the process of feeding glass sheets onto the cutting machine accurately and efficiently?

- Properly align the glass sheet on the machine bed, ensuring it is parallel to the cutting guides.

- Use suction cups or vacuum devices to securely hold the glass sheet in place.

- Operate the machine’s feeder mechanism to move the sheet onto the cutting table.

- Check for any misalignments or defects in the sheet before starting the cutting process.

2. How do you ensure the accuracy of cuts made by the machine?

Calibration and Maintenance

- Calibrate the machine’s cutting head and blade regularly to ensure precision.

- Check and replace worn or damaged blades to prevent deviations in cuts.

- Monitor the machine’s software to identify any potential errors or malfunctions.

Material Handling

- Inspect the glass sheet for irregularities, scratches, or cracks that might affect the cutting process.

- Ensure the sheet is properly loaded and secured on the machine’s bed to avoid movement during cutting.

3. What safety precautions do you take while operating the glass cutting machine?

- Wear appropriate protective gear, including gloves, safety glasses, and a dust mask.

- Ensure the machine is properly grounded and electrically isolated to prevent shocks.

- Inspect the machine and cutting area regularly for any potential hazards, such as loose wires or debris.

- Follow established safety procedures for handling and storing glass sheets.

4. How do you deal with different types of glass materials and their cutting requirements?

- Identify the type of glass and its specific properties, such as thickness, hardness, and clarity.

- Adjust the machine’s cutting parameters, such as speed and pressure, to suit the material’s characteristics.

- Utilize specialized cutting blades and techniques for specific glass types, such as laminated or tempered glass.

- Follow manufacturer guidelines and industry best practices for cutting different glass materials.

5. Describe the maintenance procedures you perform on the glass cutting machine?

- Regularly clean and lubricate the machine’s components, including the cutting head, guides, and bed.

- Check and replace filters and air lines to ensure proper operation and air flow.

- Inspect and tighten loose nuts, bolts, and screws to maintain stability and accuracy.

- Monitor the machine’s performance and report any unusual noises, vibrations, or errors to maintenance personnel.

6. How do you troubleshoot common problems that may occur during the glass cutting process?

- Identify the source of the problem by observing the machine’s behavior and error messages.

- Check the glass sheet for defects, misalignment, or contamination that could affect the cut.

- Inspect the cutting blade for damage, dullness, or improper alignment.

- Refer to the machine’s user manual or seek guidance from experienced technicians for specific troubleshooting steps.

7. What are the key quality control measures you implement to ensure the quality of cut glass pieces?

- Perform regular inspections of the cut glass to check for accuracy, cleanliness, and absence of defects.

- Use measuring tools and gauges to verify the dimensions and tolerances of the cut pieces.

- Implement a quality control system to document inspections and track any production issues.

- Provide feedback to the machine operators and maintenance team to improve processes and maintain high standards.

8. How do you work as a team to ensure efficient and productive glass cutting operations?

- Communicate effectively with fellow operators, supervisors, and maintenance personnel.

- Assist others with loading, unloading, and handling glass sheets to maintain a smooth workflow.

- Share knowledge and best practices to enhance team performance and problem-solving capabilities.

- Maintain a clean and organized work area to promote safety and efficiency.

9. What are the different types of glass cutting machines and their applications?

- Manual Glass Cutters: Used for straight cuts on smaller pieces of glass.

- Electric Glass Cutters: Provide more precision and power for cutting larger glass sheets.

- CNC (Computer Numerical Control) Glass Cutters: Automated machines that cut complex shapes and designs.

- Waterjet Glass Cutters: Use a high-pressure water jet to cut through glass without generating dust.

- Laser Glass Cutters: Utilize a laser beam to precisely cut complex shapes and patterns in glass.

10. Explain the advantages and disadvantages of using a CNC glass cutting machine over a manual glass cutter?

Advantages of CNC Glass Cutting Machines

- Precision and Accuracy: CNC machines provide greater precision and accuracy in cutting, reducing waste and rework.

- Complex Designs: They can cut intricate and complex designs that would be difficult or impossible to achieve manually.

- Automation: CNC machines automate the cutting process, freeing up operators for other tasks.

- Speed: CNC machines can cut at faster speeds, increasing productivity.

Disadvantages of CNC Glass Cutting Machines

- Cost: CNC machines are more expensive than manual cutters.

- Complexity: Operating CNC machines requires technical knowledge and training.

- Size Limitations: CNC machines may have size limitations, restricting the size of glass that can be cut.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Cutting Machine Feeder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Cutting Machine Feeder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Glass Cutting Machine Feeder is responsible for efficiently supplying glass sheets to a cutting machine in a production environment. Their key duties include:

1. Glass Sheet Preparation

Preparing glass sheets by cleaning, inspecting, and ensuring they meet the required specifications.

2. Machine Operation

Loading and positioning glass sheets onto the conveyor belt of the cutting machine.

Monitoring the machine’s operation to ensure accurate and consistent cutting.

Adjusting machine settings as needed to optimize cutting performance.

3. Quality Assurance

Inspecting cut glass sheets for defects or imperfections.

Ensuring that the finished products meet the required quality standards.

4. Maintenance

Performing regular maintenance and cleaning of the cutting machine and its accessories.

Reporting any equipment issues or malfunctions promptly.

5. Safety Precautions

Adhering to all safety regulations and using proper protective gear.

Handling and storing glass sheets safely to prevent breakage or injuries.

Interview Tips

To ace the interview for a Glass Cutting Machine Feeder position, candidates should:

1. Research the Company

Familiarize themselves with the company’s products, processes, and industry reputation.

Understanding the company’s culture and values can demonstrate alignment with their goals.

2. Highlight Relevant Skills

Emphasize skills and experience in glass handling, machine operation, and quality inspection.

Quantify achievements and provide specific examples of successful outcomes.

3. Demonstrate Safety Awareness

Stress their commitment to safety and familiarity with glass handling protocols.

Provide examples of implementing safety measures or mitigating risks in previous roles.

4. Show Attention to Detail

Explain their meticulous approach to ensuring accuracy and precision in their work.

Highlight their ability to identify and rectify errors.

5. Be Prepared for Technical Questions

Review the basics of glass cutting machinery, including different types of cutters and their applications.

Be ready to discuss common troubleshooting techniques and maintenance procedures.

6. Practice Common Interview Questions

Prepare answers to common interview questions about experience, skills, and motivation.

Practice delivering clear and concise responses that showcase relevant qualifications.

7. Dress Professionally

Maintain a professional appearance that reflects the role’s requirements.

Dress appropriately for a manufacturing environment, considering safety and comfort.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glass Cutting Machine Feeder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!