Are you gearing up for an interview for a Glass Cutting or Grinding Production Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Glass Cutting or Grinding Production Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

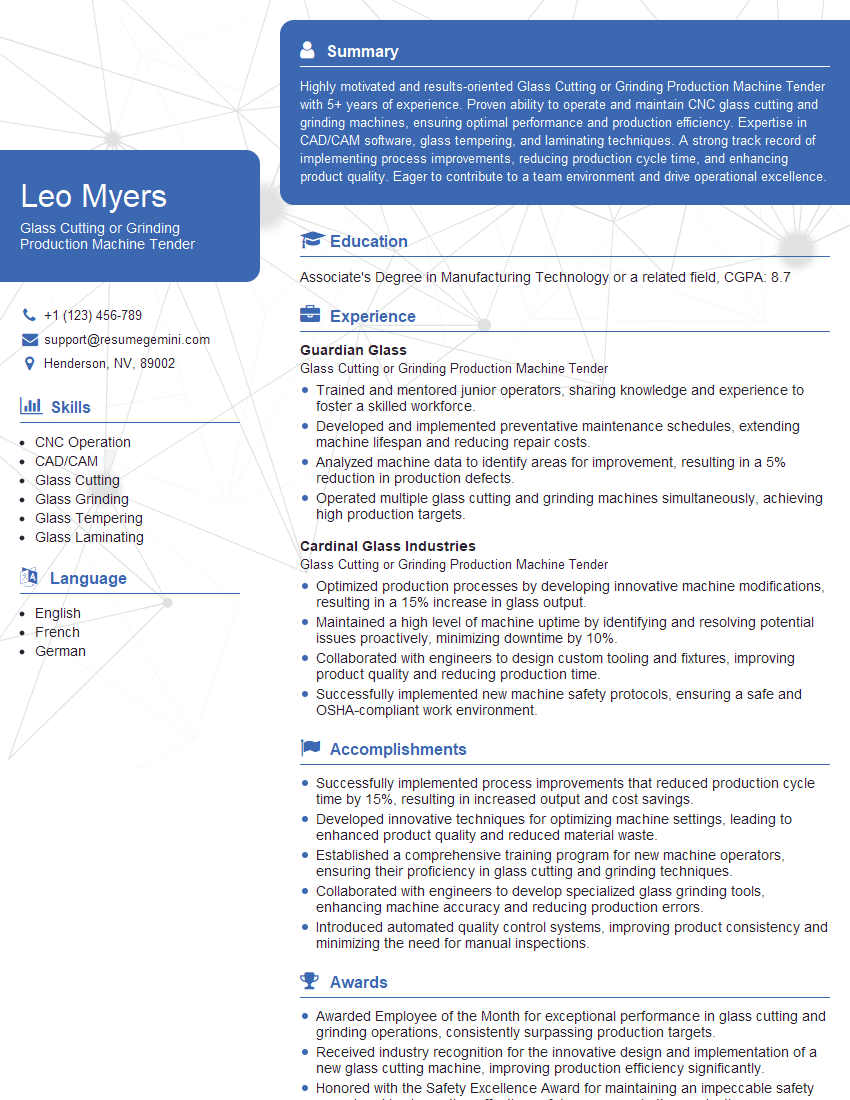

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Cutting or Grinding Production Machine Tender

1. Explain the different types of glass cutting machines and their applications?

- Diamond-tipped saws: These are used for cutting straight lines and curves in glass. They are the most common type of glass cutting machine.

- Waterjet cutters: These use a high-pressure stream of water to cut glass. They can cut complex shapes and are often used for cutting intricate designs.

- Laser cutters: These use a laser to cut glass. They are very precise and can cut complex shapes. They are often used for cutting delicate glass objects.

2. What are the safety precautions that must be taken when operating a glass cutting machine?

Proper training

- Wear appropriate safety gear, including safety glasses, gloves, and a dust mask.

- Keep the work area clean and free of debris.

- Inspect the machine before each use to ensure that it is in good working order.

- Never operate the machine if you are tired or under the influence of alcohol or drugs.

During operation

- Always be aware of your surroundings and the location of other people.

- Never place your hands or fingers near the cutting blade.

- Secure the glass firmly in place before cutting.

- Use the correct cutting speed and pressure for the type of glass being cut.

- Never force the machine.

3. How do you maintain a glass cutting machine?

- Clean the machine regularly to remove dust and debris.

- Inspect the cutting blade and replace it if it becomes dull or damaged.

- Lubricate the moving parts of the machine according to the manufacturer’s instructions.

- Calibrate the machine regularly to ensure that it is cutting accurately.

4. What are the different types of glass grinding machines and their applications?

- Surface grinders: These are used for grinding flat surfaces on glass. They are often used for grinding the edges of glass panes.

- Cylindrical grinders: These are used for grinding cylindrical surfaces on glass. They are often used for grinding the inside of glass bottles.

- Centerless grinders: These are used for grinding the outside of cylindrical glass objects. They are often used for grinding the outside of glass bottles.

5. What are the safety precautions that must be taken when operating a glass grinding machine?

Proper training

- Wear appropriate safety gear, including safety glasses, gloves, and a dust mask.

- Keep the work area clean and free of debris.

- Inspect the machine before each use to ensure that it is in good working order.

- Never operate the machine if you are tired or under the influence of alcohol or drugs.

During operation

- Always be aware of your surroundings and the location of other people.

- Never place your hands or fingers near the grinding wheel.

- Secure the glass firmly in place before grinding.

- Use the correct grinding speed and pressure for the type of glass being ground.

- Never force the machine.

6. How do you maintain a glass grinding machine?

- Clean the machine regularly to remove dust and debris.

- Inspect the grinding wheel and replace it if it becomes worn or damaged.

- Lubricate the moving parts of the machine according to the manufacturer’s instructions.

- Calibrate the machine regularly to ensure that it is grinding accurately.

7. What are the different types of production machines used in the glass industry?

- Glass cutting machines

- Glass grinding machines

- Glass polishing machines

- Glass tempering machines

- Glass laminating machines

- Glass bending machines

- Glass decorating machines

8. What are the safety precautions that must be taken when working in a glass production facility?

Proper training

- Wear appropriate safety gear, including safety glasses, gloves, and a dust mask.

- Keep the work area clean and free of debris.

- Inspect the machines before each use to ensure that they are in good working order.

- Never operate a machine if you are tired or under the influence of alcohol or drugs.

During operation

- Always be aware of your surroundings and the location of other people.

- Never place your hands or fingers near moving parts of machines.

- Secure the glass firmly in place before processing.

- Use the correct machine settings for the type of glass being processed.

- Never force a machine.

9. What are the quality control procedures that are used in the glass industry?

- Visual inspection

- Dimensional inspection

- Optical inspection

- Mechanical testing

- Electrical testing

- Environmental testing

10. What are the emerging trends in the glass industry?

- The use of new materials, such as tempered glass and laminated glass.

- The development of new technologies, such as glass bending and glass decorating.

- The increasing use of glass in construction and automotive applications.

- The growing demand for sustainable glass products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Cutting or Grinding Production Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Cutting or Grinding Production Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glass Cutting or Grinding Production Machine Tenders are responsible for operating and maintaining glass cutting or grinding machines to cut, grind, or polish glass products.

1. Operating Machines

Tenders are responsible for setting up, operating, and adjusting glass cutting or grinding machines to meet production specifications.

- Load and unload glass sheets or other materials onto machines.

- Adjust machine settings to ensure accurate cutting or grinding.

- Monitor machines during operation and make adjustments as needed.

2. Inspecting Products

Tenders are responsible for inspecting finished products to ensure they meet quality standards.

- Inspect products for defects, such as cracks, chips, or scratches.

- Measure products to ensure they meet specifications.

- Sort and grade products based on quality.

3. Maintaining Machines

Tenders are responsible for performing routine maintenance on glass cutting or grinding machines.

- Clean and lubricate machines.

- Inspect machines for wear and tear.

- Perform minor repairs and adjustments.

4. Safety

Tenders are responsible for following all safety regulations and procedures.

- Wear appropriate safety gear, such as gloves, goggles, and earplugs.

- Operate machines in a safe manner.

- Report any safety hazards or concerns.

Interview Tips

Interviewing for a position as a Glass Cutting or Grinding Production Machine Tender can be a competitive process. By following these tips, you can increase your chances of success.

1. Research the Company

Before the interview, take the time to research the company you are applying to. This will help you understand their business, culture, and values.

- Visit the company website.

- Read articles about the company in the news.

- Talk to people who work at the company.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Questions about your experience and qualifications.

- Questions about your skills and abilities.

- Questions about your motivation and goals.

3. Be Prepared to Talk About Your Experience

Highlight your experience and qualifications that are relevant to the position. Be specific about your accomplishments and how they have helped you succeed in the past.

- Give examples of times when you have operated glass cutting or grinding machines.

- Describe your experience with inspecting and grading products.

- Explain how you have maintained and repaired glass cutting or grinding machines.

4. Be Yourself

The most important thing is to be yourself during the interview. Employers are looking for people who are genuine and authentic.

- Don’t try to be someone you’re not.

- Be honest about your experience and qualifications.

- Show your passion for the position and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Glass Cutting or Grinding Production Machine Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.