Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Glass Driller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

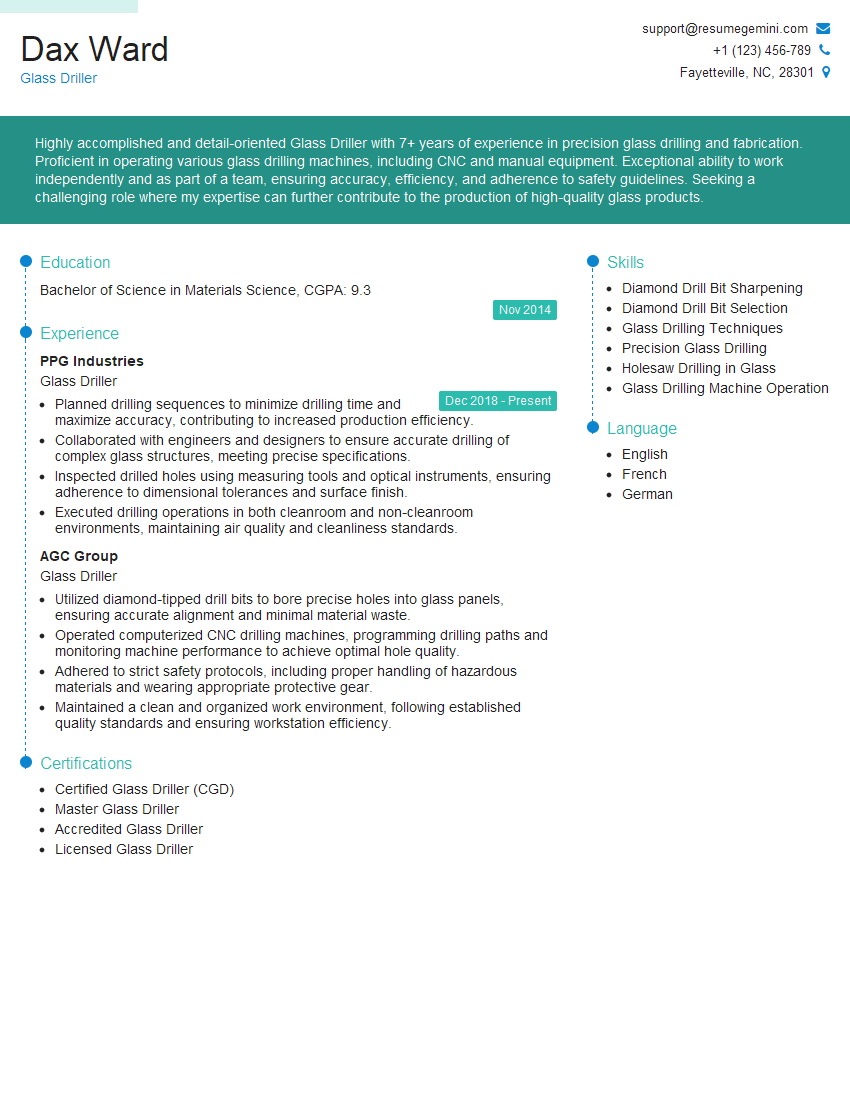

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Driller

1. Describe the different types of glass drills and their applications?

- Diamond core drills: These are used for drilling holes in glass, ceramic, and other hard materials. They use a diamond-tipped bit to cut through the material.

- Tungsten carbide drills: These are used for drilling holes in glass, metal, and other materials. They use a tungsten carbide-tipped bit to cut through the material.

- Carbide tipped drills: These are used for drilling holes in glass, metal, and other materials. They use a carbide-tipped bit to cut through the material.

- Annular cutters: These are used for drilling large holes in glass. They use a hollow bit to cut out a circle of glass.

2. What are the safety precautions that must be taken when drilling glass?

- Wear safety glasses and gloves to protect your eyes and hands from flying glass.

- Secure the glass workpiece firmly in place before drilling.

- Use a sharp drill bit and apply constant pressure to avoid breaking the glass.

- Lubricate the drill bit with water or a cutting oil to reduce friction and prevent overheating.

- Drill slowly and carefully, and be aware of the thickness of the glass.

: Types of Safety Glasses

- Impact-resistant safety glasses: These are made of polycarbonate or another impact-resistant material and are designed to protect your eyes from flying objects.

- Laser safety glasses: These are made of a material that blocks specific wavelengths of light, such as laser light, to protect your eyes from damage.

- Prescription safety glasses: These are safety glasses that have been fitted with prescription lenses to correct your vision.

Subheading: Types of Gloves

- Nitrile gloves: These are made of a synthetic rubber and are resistant to punctures and chemicals.

- Latex gloves: These are made of natural rubber and are not as resistant to punctures as nitrile gloves.

- Leather gloves: These are made of leather and are resistant to heat and abrasion.

3. How do you determine the correct drill bit size for a given hole?

- Measure the diameter of the hole you need to drill.

- Choose a drill bit that is slightly smaller than the diameter of the hole.

- For example, if you need to drill a 1/4-inch hole, use a 3/16-inch drill bit.

4. What is the purpose of a pilot hole when drilling glass?

- A pilot hole is a small hole that is drilled before the main hole.

- It helps to guide the drill bit and prevent the glass from breaking.

5. What are the different methods for drilling holes in glass?

- Hand drilling: This is the simplest method of drilling holes in glass. It involves using a hand drill and a glass drill bit.

- Machine drilling: This method uses a drill press to drill holes in glass. It is more accurate and efficient than hand drilling.

- Water jet cutting: This method uses a high-pressure jet of water to cut holes in glass. It is a precise and versatile method, but it can be expensive.

6. What are the advantages and disadvantages of using a diamond drill bit for drilling glass?

- Diamond drill bits are very hard and can cut through glass quickly and easily.

- They are durable and can be used for a long time.

- Diamond drill bits are expensive.

- They can be difficult to sharpen.

Advantages:

Disadvantages:

7. How do you maintain a glass drill bit?

- Clean the drill bit after each use.

- Sharpen the drill bit when it becomes dull.

- Store the drill bit in a dry place.

8. What are the common problems that can occur when drilling glass?

- The glass can break

- The drill bit can become dull

- The drill bit can overheat

9. How do you troubleshoot a problem when drilling glass?

- If the glass breaks, try using a smaller drill bit or drilling at a slower speed.

- If the drill bit becomes dull, sharpen it.

- If the drill bit overheats, stop drilling and let it cool down.

10. What are the different types of glass that can be drilled?

- Annealed glass: This is the most common type of glass and is relatively easy to drill.

- Tempered glass: This type of glass is much harder than annealed glass and is more difficult to drill.

- Laminated glass: This type of glass is made up of two or more layers of glass that are bonded together with a plastic interlayer. It is very difficult to drill.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Driller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Driller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glass Drillers, also known as Glass Machinists, play a crucial role in various industries by specializing in the fabrication and shaping of glass components. Their responsibilities include:

1. Drilling and Cutting Glass

Precisely drilling holes and cutting intricate shapes in glass using specialized equipment and techniques.

- Operating CNC (Computer Numerical Control) machines to automate drilling and cutting processes.

- Using manual tools such as diamond drills and saws to create custom designs and shapes.

2. Polishing and Finishing Glass

Smoothing and polishing glass surfaces to achieve desired aesthetics and functionality.

- Using abrasives and polishing agents to remove burrs and create a smooth finish.

- Applying coatings or glazes to enhance the glass’s appearance and durability.

3. Installing Glass Components

Safely installing glass components in various applications, such as furniture, windows, and architectural structures.

- Measuring, marking, and cutting glass to fit specific dimensions.

- Using adhesives, sealants, and other materials to secure glass components and ensure weatherproofing.

4. Maintaining Equipment and Workspace

Ensuring the proper functioning and cleanliness of equipment and work areas.

- Calibrating and maintaining CNC machines, drills, and saws.

- Maintaining a clean and organized workspace to minimize hazards and improve efficiency.

Interview Tips

To ace the interview for a Glass Driller position, consider the following tips:

1. Research the Company and Position

Thoroughly research the company’s background, industry, and specific job requirements. This will demonstrate your interest and understanding of the role.

2. Highlight Relevant Skills and Experience

Emphasize your expertise in drilling, cutting, polishing, and installing glass. Quantify your accomplishments and provide specific examples of projects you’ve worked on.

3. Showcase Safety Knowledge

Stress your understanding of safety protocols when working with glass and machinery. Discuss your experience in handling hazardous materials and preventing accidents.

4. Demonstrate Attention to Detail

Convey your meticulous nature and ability to produce high-quality work. Describe your commitment to accuracy and precision in all aspects of your job.

5. Be Prepared for Technical Questions

Review common glass drilling techniques, equipment, and safety procedures. Practice answering questions related to the technical aspects of the role.

6. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview and arrive on time to show respect for the interviewer’s schedule.

7. Be Enthusiastic and Confident

Display enthusiasm for the job and the industry. Confidence in your abilities will make a positive impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glass Driller interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.