Feeling lost in a sea of interview questions? Landed that dream interview for Glass-Lined Tank Repairer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Glass-Lined Tank Repairer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

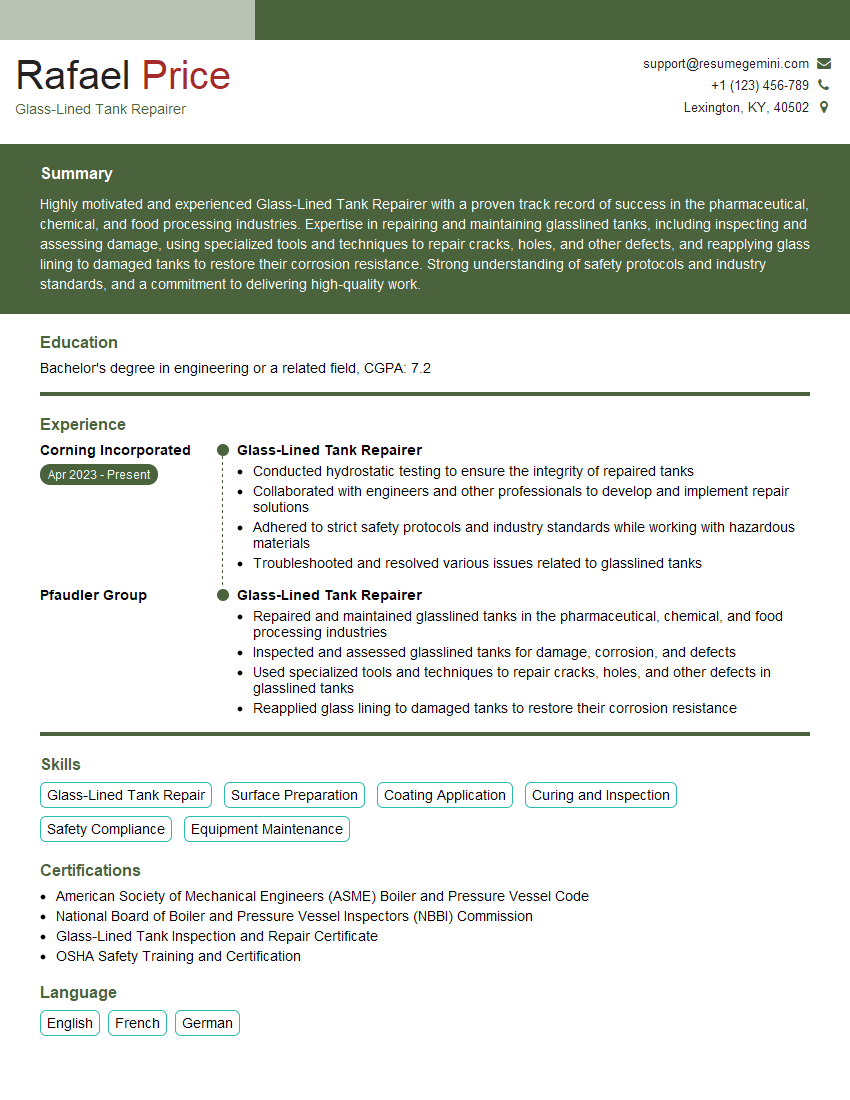

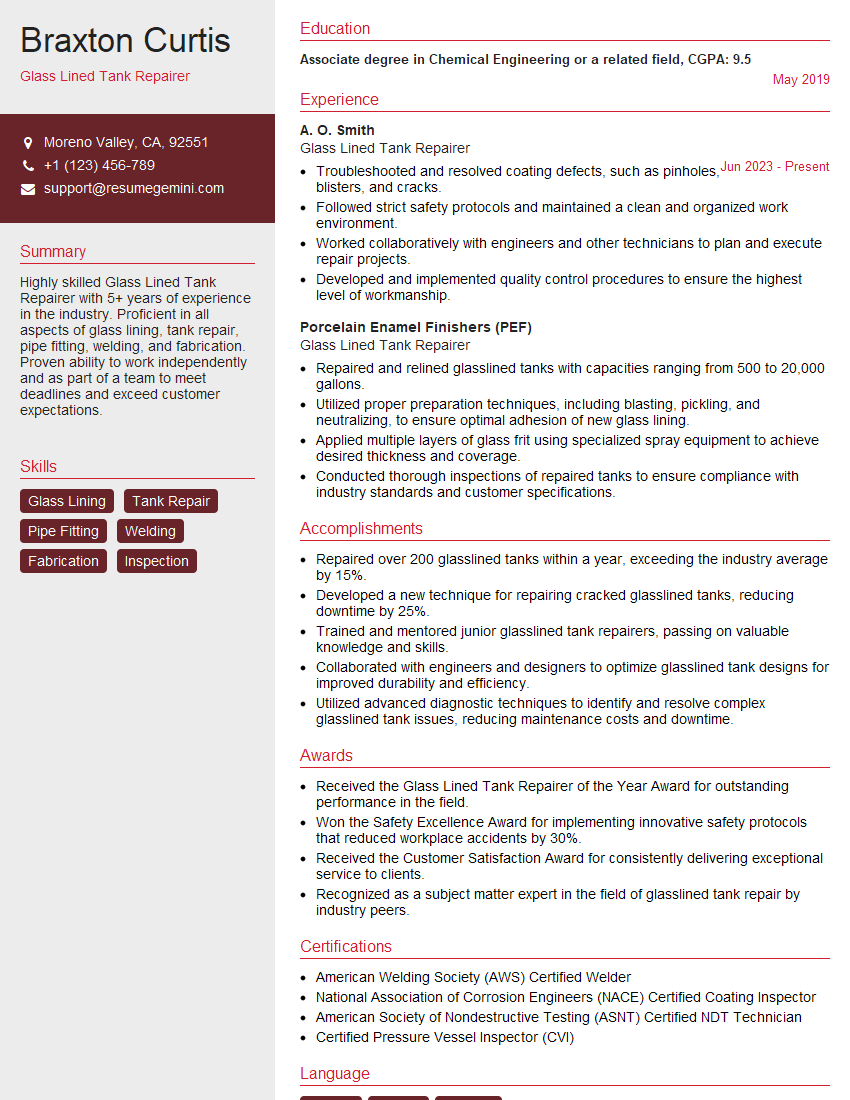

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass-Lined Tank Repairer

1. What are the different types of glass-lined tanks?

There are two main types of glass-lined tanks:

- Horizontal glass-lined tanks

- Vertical glass-lined tanks

2. What are the advantages of using glass-lined tanks?

Glass-lined tanks offer several advantages over other types of tanks, including:

- Corrosion resistance

- Chemical resistance

- High temperature resistance

- Easy to clean and maintain

3. What are the different methods of repairing glass-lined tanks?

There are several different methods of repairing glass-lined tanks, including:

- Patch repairs

- Full relining

- Electrochemical deposition

4. What are the factors to consider when selecting a method of repairing a glass-lined tank?

The following factors should be considered when selecting a method of repairing a glass-lined tank:

- The size and location of the damage

- The type of glass lining

- The operating conditions of the tank

- The cost of the repair

5. What are the steps involved in repairing a glass-lined tank?

The steps involved in repairing a glass-lined tank typically include:

- Preparing the surface of the tank

- Applying the repair material

- Curing the repair material

- Testing the repair

6. What are the common problems that can occur with glass-lined tanks?

The common problems that can occur with glass-lined tanks include:

- Corrosion

- Erosion

- Cracking

- Delamination

7. How can you prevent problems from occurring with glass-lined tanks?

Problems with glass-lined tanks can be prevented by:

- Properly selecting and installing the tank

- Maintaining the tank in accordance with the manufacturer’s instructions

- Regularly inspecting the tank for damage

- Promptly repairing any damage that is found

8. What are the safety precautions that must be taken when working with glass-lined tanks?

The following safety precautions must be taken when working with glass-lined tanks:

- Wear appropriate personal protective equipment (PPE)

- Follow the manufacturer’s instructions for handling and storing the repair materials

- Be aware of the potential hazards associated with the repair process

- Take steps to minimize the risk of accidents

9. What are the industry standards for repairing glass-lined tanks?

The industry standards for repairing glass-lined tanks are set by the Steel Tank Institute (STI) and the National Board of Boiler and Pressure Vessel Inspectors (NBBI).

10. What are the latest trends in glass-lined tank repair?

The latest trends in glass-lined tank repair include:

- The use of new materials and techniques to improve the durability and performance of repairs

- The development of new methods to reduce the cost of repairs

- The increased use of automation to improve the efficiency and accuracy of repairs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass-Lined Tank Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass-Lined Tank Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Repair and Maintain Glass-Lined Tanks

Glass-lined tank repairers are responsible for the repair and maintenance of glass-lined tanks used in various industries, such as chemical processing, food and beverage, and pharmaceuticals.

- Inspect tanks for damage, such as cracks, chips, and leaks.

- Repair or replace damaged glass lining using specialized techniques and materials.

- Conduct pressure and leak tests to ensure the integrity of the repaired tanks.

2. Supervise and Train Staff

In some cases, glass-lined tank repairers may be responsible for supervising and training staff involved in the repair and maintenance of tanks.- Train new employees on proper repair techniques and safety procedures.

- Supervise staff to ensure they are following established protocols.

- Monitor the performance of staff and provide feedback to improve their skills.

3. Ensure Safety and Compliance

It is crucial for glass-lined tank repairers to prioritize safety and compliance in their work.- Follow all safety regulations and guidelines.

- Use personal protective equipment (PPE) and ensure that staff follows the same.

- Handle hazardous materials safely and dispose of waste materials properly.

- Stay up-to-date on industry best practices and standards.

4. Maintain a Clean and Organized Work Environment

A clean and organized work environment is essential for efficient and safe work.- Keep work areas clean and free of debris.

- Inspect equipment regularly and maintain it in good working condition.

- Organize materials and tools for easy access.

- Dispose of waste materials properly to avoid contamination.

Interview Tips

Preparing for an interview for a glass-lined tank repairer position requires a combination of technical knowledge and soft skills.

1. Research the Company and Industry

Before the interview, take time to research the company and the industry. Show that you are interested in the role and are knowledgeable about the industry in which the company operates.

- Look at company’s website

- Check LinkedIn profiles of current employees

- Review industry news/articles

2. Highlight Your Experience and Skills

During the interview, emphasize your relevant experience and skills. Be specific and provide examples to support your claims.

- Describe your experience in repairing glass-lined tanks

- Quantify your accomplishments when possible

- Highlight your technical skills and knowledge

3. Demonstrate Your Safety Awareness

As safety is crucial in this industry, emphasize your commitment to safety and compliance. Explain your understanding of safety protocols and how you have adhered to them in previous roles.

- Explain your knowledge of safety regulations

- Describe how you have followed safety procedures in the past

- Highlight any safety certifications or training you have completed

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions that show you have researched the company and are interested in the role.

- About the company’s growth plans

- How the role contributes to the team

- The company’s commitment to training and professional development

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Glass-Lined Tank Repairer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Glass-Lined Tank Repairer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.