Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Glass Sander position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

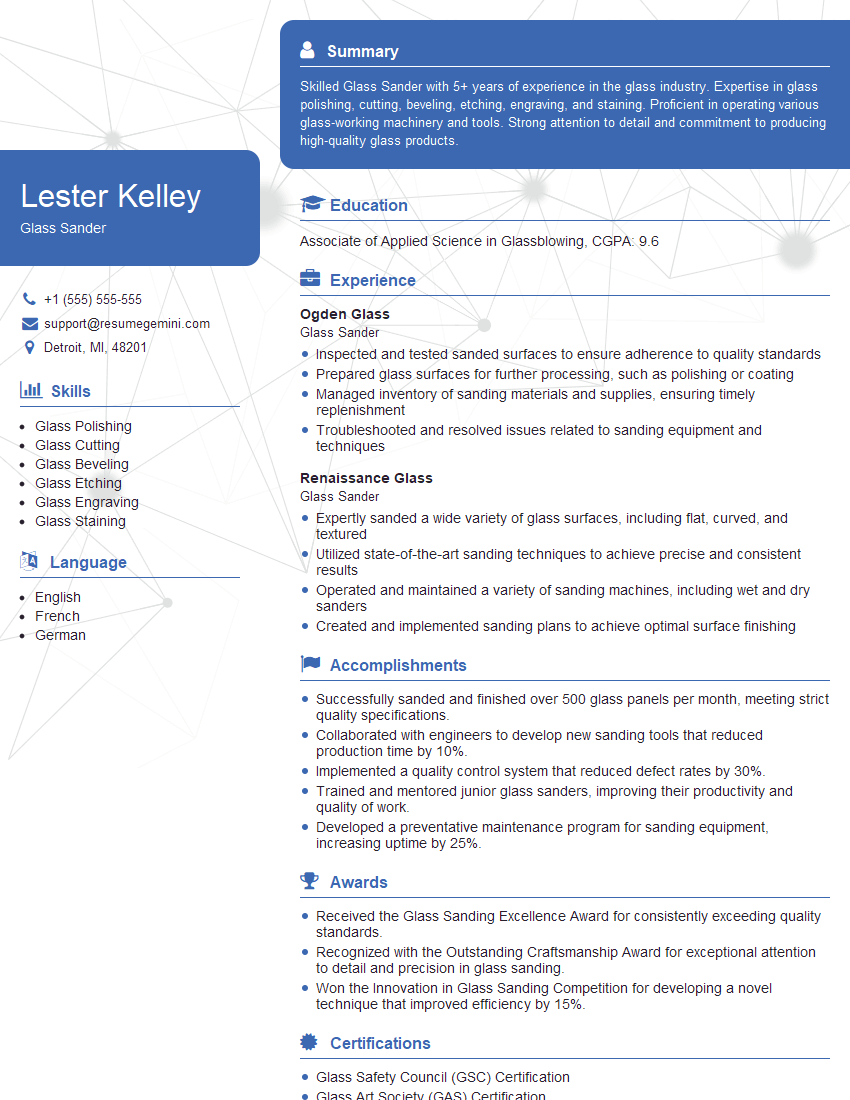

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Sander

1. What are the different abrasive materials used in glass sanding?

Abrasive materials used in glass sanding include:

- Diamond

- Boron carbide

- Cerium oxide

- Silicon carbide

2. Describe the process of edge-smoothing glass

Flat edges

- Use a diamond sanding wheel to create a slight chamfer on the edge

- Follow with a finer-grit wheel to smooth the chamfer

Beveled edges

- Use a series of sanding wheels to create the desired bevel

- Start with a coarse-grit wheel and gradually move to finer grits

3. What are the safety precautions to observe when sanding glass?

Safety precautions include:

- Wear appropriate safety gear (respirator, gloves, eye protection)

- Secure the glass properly to prevent movement during sanding

- Use a well-ventilated area or exhaust system to remove dust

- Handle glass edges carefully to avoid cuts

4. Explain the difference between single-pass and multi-pass sanding

- Single-pass sanding involves making a single pass over the surface with a sanding tool

- Multi-pass sanding involves making multiple passes with the sanding tool, using different grit sizes

5. What factors affect the sanding speed of glass?

- Type of abrasive material – Different abrasives have different cutting rates

- Grit size of the abrasive – Finer grits remove material more slowly

- Speed of the sanding tool – Faster speeds can result in higher sanding rates

- Condition of the glass surface – Damaged or uneven surfaces may require more sanding

6. What are the different types of sanding machines used in glass sanding?

- Handheld sanders – Used for small-scale or intricate sanding

- Bench grinders – Used for sanding flat or curved surfaces

- CNC sanders – Used for automated, high-precision sanding

- Robotic sanders – Used for complex or dangerous sanding applications

7. How do you determine the appropriate grit size for sanding glass?

Factors to consider include:

- Desired finish – Rougher finishes require coarser grits, while finer finishes require finer grits

- Type of glass – Different glass types have different sanding requirements

- Sanding machine – Different machines may require different grit sizes

8. What techniques can be used to achieve a high-quality finish when sanding glass?

- Use a sharp abrasive – Dull or worn abrasives will produce poor-quality finishes

- Maintain a consistent sanding speed – Varying the speed can result in uneven finishes

- Use a light touch – Applying too much pressure can result in chipping or scratching

- Keep the glass surface clean – Dust and debris can interfere with the sanding process

9. How do you inspect a glass surface after sanding to ensure it meets specifications?

- Visual inspection – Inspect the surface for scratches, chips, or other defects

- Dimensional inspection – Measure the surface to ensure it meets the required dimensions

- Surface roughness measurement – Use a profilometer to measure the surface roughness and ensure it meets the specified tolerance

10. What are the common mistakes made by glass sanders and how can they be avoided?

- Using the wrong grit size – Using too coarse of a grit can damage the glass, while using too fine of a grit can result in a slow sanding process

- Applying too much pressure – Applying too much pressure can result in chipping or scratching the glass

- Not using a sharp abrasive – Dull or worn abrasives will produce poor-quality finishes

- Not cleaning the glass surface properly – Dust and debris can interfere with the sanding process and result in poor finishes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Sander.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Sander‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glass Sanders are skilled craftspeople who use specialized equipment to smooth, shape, and polish glass surfaces. They play a vital role in creating a wide range of glass products, including windows, mirrors, and decorative pieces.

1. Sanding and Polishing Glass

The primary responsibility of a Glass Sander is to sand and polish glass to achieve a desired surface finish. This involves using various sanding belts and polishing wheels to remove imperfections, smooth rough edges, and create a glossy or matte finish.

- Operate sanding machines to remove surface imperfections from glass.

- Polish glass surfaces to achieve a desired finish, using a variety of polishing wheels and compounds.

2. Shaping and Beveling Glass

Glass Sanders may also be involved in shaping and beveling glass to create custom designs. This requires using specialized equipment to cut, grind, and shape the glass to meet specific dimensions and angles.

- Use grinders and cutting tools to shape glass according to specifications.

- Create beveled edges on glass surfaces using specialized equipment.

3. Inspecting and Cleaning Glass

Glass Sanders are responsible for inspecting the finished product to ensure it meets quality standards. They also clean and prepare the glass surface before and after sanding and polishing.

- Inspect glass surfaces for defects or imperfections.

- Clean and prepare glass surfaces before and after processing.

4. Maintaining Equipment

Glass Sanders are responsible for maintaining the equipment they use, including sanders, polishers, and other specialized tools. This involves regular cleaning, lubrication, and troubleshooting.

- Perform regular maintenance and cleaning of sanding and polishing equipment.

- Identify and troubleshoot equipment problems, ensuring optimal performance.

Interview Tips

Preparing thoroughly for a Glass Sander interview is essential to showcase your skills and make a positive impression on the hiring manager.

1. Research the Company and Position

Take the time to research the company and the specific Glass Sander position you are applying for. This will help you understand their business, industry, and the specific requirements of the role.

- Visit the company website and social media pages.

- Read industry publications and articles to stay updated on the latest techniques and trends.

2. Highlight Your Skills and Experience

Be prepared to discuss your skills and experience in sanding and polishing glass, shaping and beveling, and maintaining equipment. Quantify your accomplishments whenever possible to demonstrate your value.

- Provide specific examples of projects you have worked on.

- Quantify your results, such as the number of pieces sanded or the time saved by optimizing equipment.

3. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare your responses in advance. This will help you feel more confident and articulate during the interview.

- Why are you interested in this position?

- What experience do you have in glass sanding and polishing?

- How do you ensure the quality of your work?

4. Be Professional and Enthusiastic

Dress professionally, arrive on time, and maintain a positive attitude throughout the interview. Demonstrate your enthusiasm for the position and the opportunity to contribute to the company.

- Make eye contact, smile, and show interest in the conversation.

- Ask thoughtful questions about the company and the position.

Next Step:

Now that you’re armed with the knowledge of Glass Sander interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Glass Sander positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini