Are you gearing up for a career in Glaze Handler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Glaze Handler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

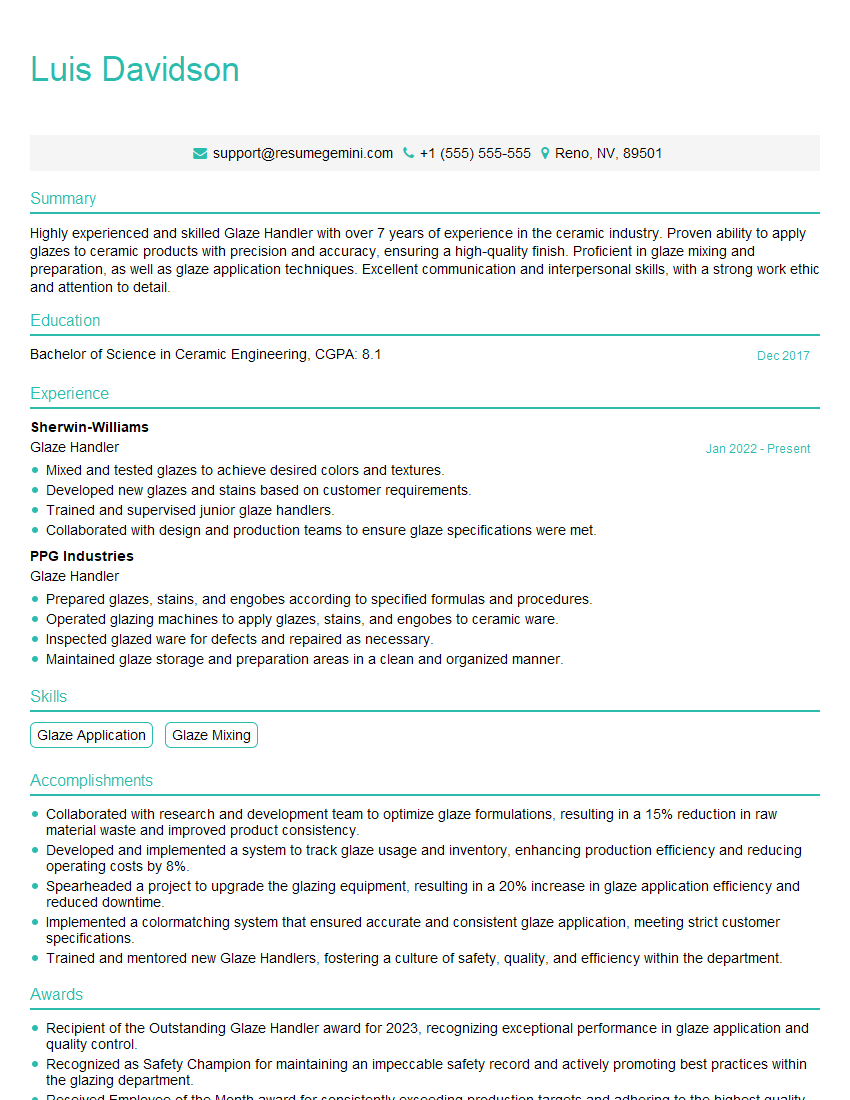

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glaze Handler

1. Describe the process of preparing glazes for application?

- Weigh the raw materials according to the recipe.

- Mill the raw materials to a fine powder.

- Add water to the powder to create a slurry.

- Mix the slurry until it is smooth and free of lumps.

- Add any necessary stains, pigments, or opacifiers.

- Mix the glaze again until it is well blended.

- Test the glaze on a small piece of bisque ware to ensure that it is the correct consistency and color.

- Adjust the glaze as necessary.

2. What are the different types of glazes?

Ceramic glazes

- Earthenware glazes

- Stoneware glazes

- Porcelain glazes

Glass glazes

- Silica glazes

- Borate glazes

- Phosphate glazes

Glazes for special effects

- Crazing glazes

- Crystalline glazes

- Celadon glazes

3. What are the factors that affect the outcome of a glaze firing?

- The type of clay body

- The thickness of the glaze application

- The firing temperature

- The firing atmosphere

- The cooling rate

4. How do you troubleshoot glaze defects?

- Identify the defect.

- Determine the cause of the defect.

- Make adjustments to the glaze recipe or firing process.

- Test the glaze again.

5. What are the safety precautions that must be taken when working with glazes?

- Wear a mask to avoid inhaling dust.

- Wear gloves to avoid skin contact.

- Work in a well-ventilated area.

- Dispose of glaze waste properly.

- Keep children and pets away from glazes.

6. What are some of the latest trends in glaze technology?

- The development of glazes that are more durable and resistant to wear.

- The use of glazes to create special effects, such as crazing and crystalline glazes.

- The use of glazes to create 3D effects.

- The use of glazes to create glazes that are more environmentally friendly.

7. What are the different types of equipment used in glaze application?

- Glaze tanks

- Glaze sprayers

- Glaze dipping machines

- Glaze brushes

8. What are the different types of firing kilns used in glaze firing?

- Electric kilns

- Gas kilns

- Wood-fired kilns

9. What are the important considerations when selecting a glaze for a particular application?

- The type of clay body

- The desired glaze finish

- The firing temperature

- The glaze application method

10. What are the most common problems encountered in glaze firing?

- Crazing

- Crawling

- Pinholing

- Blistering

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glaze Handler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glaze Handler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glaze Handlers play a crucial role in the ceramic industry, ensuring the proper application and handling of glaze materials. Their responsibilities encompass:

1. Glaze Preparation and Application

Mixing and preparing glazes according to specified formulations.

- Determining glaze consistency and viscosity.

- Applying glazes to ceramic pieces using appropriate techniques (e.g., dipping, spraying, brushing).

2. Quality Control and Inspection

Inspecting glazed pieces for defects, blemishes, and adherence to quality standards.

- Measuring glaze thickness and ensuring uniform coverage.

- Identifying and addressing glaze-related issues (e.g., cracking, peeling, discoloration).

3. Kiln Operation and Firing

Loading and unloading kilns with glazed pieces.

- Setting and monitoring kiln temperatures and firing schedules.

- Ensuring proper ventilation and safety protocols during firing.

4. Equipment Maintenance and Calibration

Maintaining and calibrating glaze application equipment (e.g., spray guns, dipping tanks).

- Cleaning and inspecting equipment regularly.

- Troubleshooting and resolving equipment malfunctions.

5. Health and Safety

Adhering to safety guidelines for handling hazardous materials (e.g., glazes, solvents).

- Wearing appropriate protective gear (e.g., respirators, gloves).

- Maintaining a clean and organized work area.

Interview Tips

To ace the interview for a Glaze Handler position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and industry reputation.

- Review the job description thoroughly and identify the key skills and qualifications required.

- Check the company website and social media for recent news and updates.

2. Highlight Your Skills and Experience

Emphasize your hands-on experience in glaze preparation, application, and kiln firing.

- Quantify your accomplishments using specific metrics and examples.

- Showcase your knowledge of glaze chemistry and firing techniques.

3. Demonstrate Quality Consciousness

Stress your attention to detail and commitment to producing high-quality glazed ceramics.

- Describe your experience in identifying and rectifying glaze defects.

- Explain your understanding of quality control standards and inspection procedures.

4. Show Your Safety Awareness

Discuss your knowledge of hazardous materials handling and safety protocols in the ceramic industry.

- Highlight your experience in maintaining a clean and organized work environment.

- Demonstrate your understanding of proper ventilation and fire safety measures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glaze Handler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.