Are you gearing up for a career in Glaze Sprayer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Glaze Sprayer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

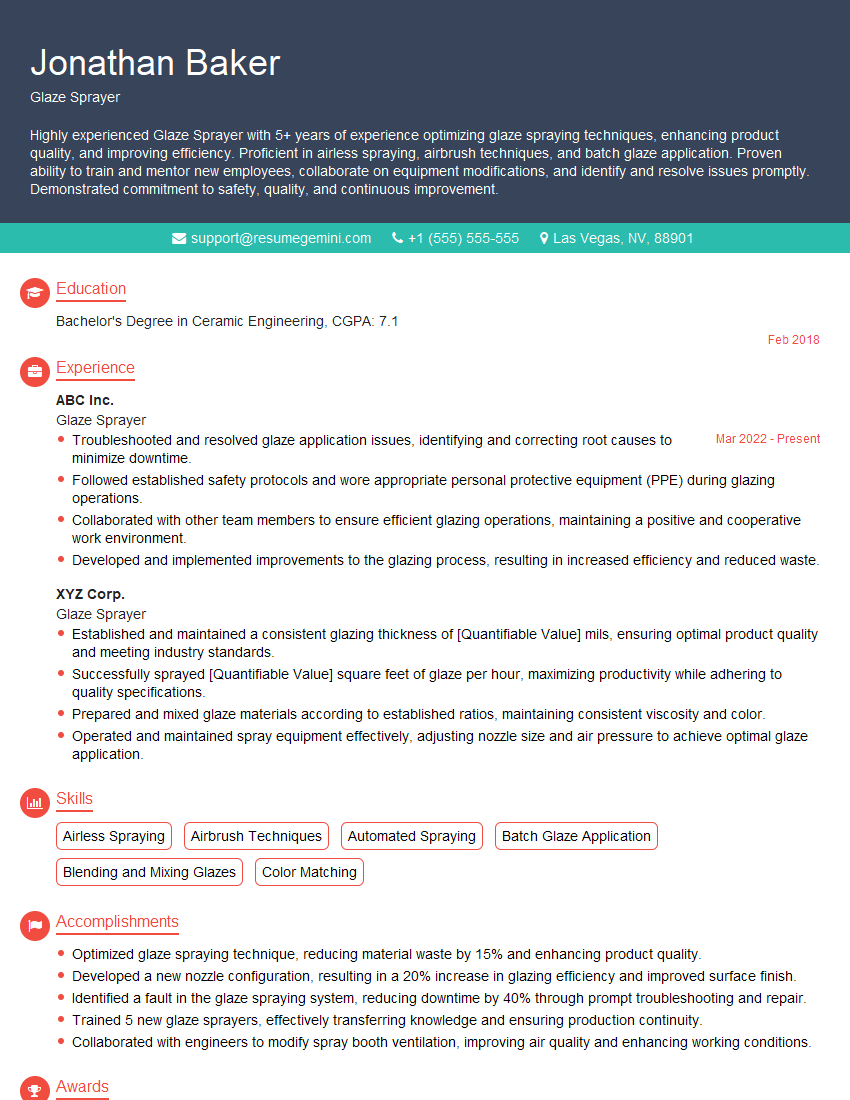

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glaze Sprayer

1. Describe the different types of glaze sprayers and their applications?

- Air-atomizing sprayers: These sprayers use compressed air to atomize the glaze, creating a fine mist that can be applied evenly to the surface of the ware.

- Airless sprayers: These sprayers use a high-pressure pump to force the glaze through a small orifice, creating a fine spray that is ideal for applying thick glazes.

- Electrostatic sprayers: These sprayers use an electrostatic charge to attract the glaze particles to the surface of the ware, resulting in a more even and consistent coating.

2. What are the key factors to consider when selecting a glaze sprayer for a particular application?

Factors to consider:

- The type of glaze being used

- The desired thickness of the glaze coating

- The size and shape of the ware being glazed

- The production volume

- The budget

3. How do you maintain and troubleshoot a glaze sprayer?

- Regularly clean the sprayer and its components to prevent clogging and ensure proper operation.

- Inspect the sprayer for any signs of damage or wear, and replace any worn or damaged parts immediately.

- Calibrate the sprayer according to the manufacturer’s instructions to ensure accurate and consistent glaze application.

- Troubleshoot any problems that may arise with the sprayer by following the manufacturer’s troubleshooting guide.

4. What safety precautions should be taken when operating a glaze sprayer?

- Wear appropriate personal protective equipment (PPE), including a respirator, gloves, and eye protection.

- Operate the sprayer in a well-ventilated area to prevent the inhalation of hazardous fumes.

- Never point the sprayer at anyone or yourself.

- Follow all manufacturer’s instructions for safe operation and maintenance of the sprayer.

5. What are the common problems that can occur with glaze sprayers and how can they be resolved?

- Clogging: This can be caused by a variety of factors, such as using the wrong type of glaze, not properly cleaning the sprayer, or using a glaze that is too thick. To resolve this issue, clean the sprayer thoroughly and use a glaze that is appropriate for the sprayer.

- Uneven spraying: This can be caused by a variety of factors, such as using the wrong nozzle size or pressure, or not holding the sprayer at the correct distance from the surface. To resolve this issue, adjust the nozzle size or pressure, or hold the sprayer at the correct distance from the surface.

- Overspray: This can be caused by using too much glaze or using a sprayer that is not properly calibrated. To resolve this issue, reduce the amount of glaze used or calibrate the sprayer according to the manufacturer’s instructions.

6. What are the different types of glazes that can be used with a glaze sprayer?

- Clear glazes: These glazes are transparent and allow the natural color of the clay to show through.

- Colored glazes: These glazes contain pigments that give them a specific color.

- Opaque glazes: These glazes are not transparent and completely cover the surface of the clay.

- Textured glazes: These glazes contain particles that give them a textured surface.

7. How do you prepare a glaze for spraying?

- Mix the glaze according to the manufacturer’s instructions.

- Strain the glaze to remove any impurities.

- Adjust the viscosity of the glaze to the correct consistency for spraying.

8. What are the different techniques for applying glaze with a sprayer?

- Single-coat spraying: This technique involves applying a single coat of glaze to the surface of the ware.

- Multi-coat spraying: This technique involves applying multiple coats of glaze to the surface of the ware.

- Dipping: This technique involves dipping the ware into a glaze bath.

- Pouring: This technique involves pouring glaze over the surface of the ware.

9. What are the different factors that can affect the quality of the glaze finish?

- The type of glaze

- The thickness of the glaze coating

- The firing temperature

- The cooling rate

- The surface texture of the ware

10. What are the different types of defects that can occur in glazed ware?

- Crazing: This defect is characterized by fine cracks in the glaze surface.

- Pinholing: This defect is characterized by small holes in the glaze surface.

- Blistering: This defect is characterized by bubbles in the glaze surface.

- Crawling: This defect is characterized by the glaze pulling away from the surface of the ware.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glaze Sprayer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glaze Sprayer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glaze Sprayers are responsible for applying glaze to ceramic ware. They use a spray gun to apply a thin, even coat of glaze to the surface of the ware. The glaze is then fired in a kiln to create a smooth, glossy finish. Glaze Sprayers may also be responsible for preparing the ware for glazing, which includes cleaning and sanding the surface. They may also be responsible for inspecting the finished ware for defects.

1. Prepare the ware for glazing

Glaze Sprayers must prepare the ware for glazing by cleaning and sanding the surface. This ensures that the glaze will adhere to the ware properly.

- Clean the ware using a mild detergent and water.

- Sand the ware to remove any rough edges or imperfections.

- Rinse the ware thoroughly to remove any dust or debris.

2. Apply the glaze to the ware

Glaze Sprayers use a spray gun to apply a thin, even coat of glaze to the surface of the ware. They must hold the spray gun at a consistent distance from the ware and move the gun smoothly across the surface. They must also be careful not to apply too much glaze, as this can cause the glaze to run or drip.

- Fill the spray gun with glaze.

- Adjust the spray gun settings to achieve the desired glaze thickness.

- Hold the spray gun at a consistent distance from the ware and move the gun smoothly across the surface.

- Apply a thin, even coat of glaze to the ware.

3. Fire the ware

Once the glaze has been applied, the ware must be fired in a kiln. This process heats the glaze to a high temperature, which causes it to melt and fuse to the surface of the ware. The firing process must be carefully controlled to ensure that the glaze does not crack or bubble.

- Place the ware in a kiln.

- Fire the ware to the desired temperature.

- Cool the ware slowly to prevent cracking.

4. Inspect the finished ware

Once the ware has been fired, it must be inspected for defects. Glaze Sprayers must look for any cracks, bubbles, or other imperfections. They must also check to make sure that the glaze is evenly applied and that there are no drips or runs.

- Inspect the ware for any cracks, bubbles, or other imperfections.

- Check to make sure that the glaze is evenly applied and that there are no drips or runs.

- Repair any defects that are found.

Interview Tips

Preparing for an interview can be stressful, but there are some things you can do to help yourself feel more confident and prepared. Here are some interview tips to help you ace your interview for a Glaze Sprayer position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also help you to answer questions about the position and your qualifications.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work for the company.

2. Prepare answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to prepare answers to these questions in advance so that you can deliver them confidently and clearly.

- Practice answering common interview questions with a friend or family member.

- Be honest and concise in your answers.

- Highlight your skills and experience that are relevant to the position.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Wear clean, pressed clothes.

- Arrive for your interview on time.

- Be polite and respectful to the receptionist and interviewer.

4. Be confident and enthusiastic

Confidence is key in an interview. Believe in yourself and your abilities, and let the interviewer know that you are excited about the position. Enthusiasm is also contagious, so let your excitement for the position shine through.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

- Show your enthusiasm for the position.

5. Ask questions

Asking questions at the end of an interview is a great way to show that you are interested in the position and that you are engaged in the conversation. It is also an opportunity to learn more about the company and the position.

- Prepare a few questions to ask the interviewer.

- Be respectful of the interviewer’s time.

- Ask questions that are relevant to the position and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Glaze Sprayer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.