Are you gearing up for an interview for a Glove Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Glove Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

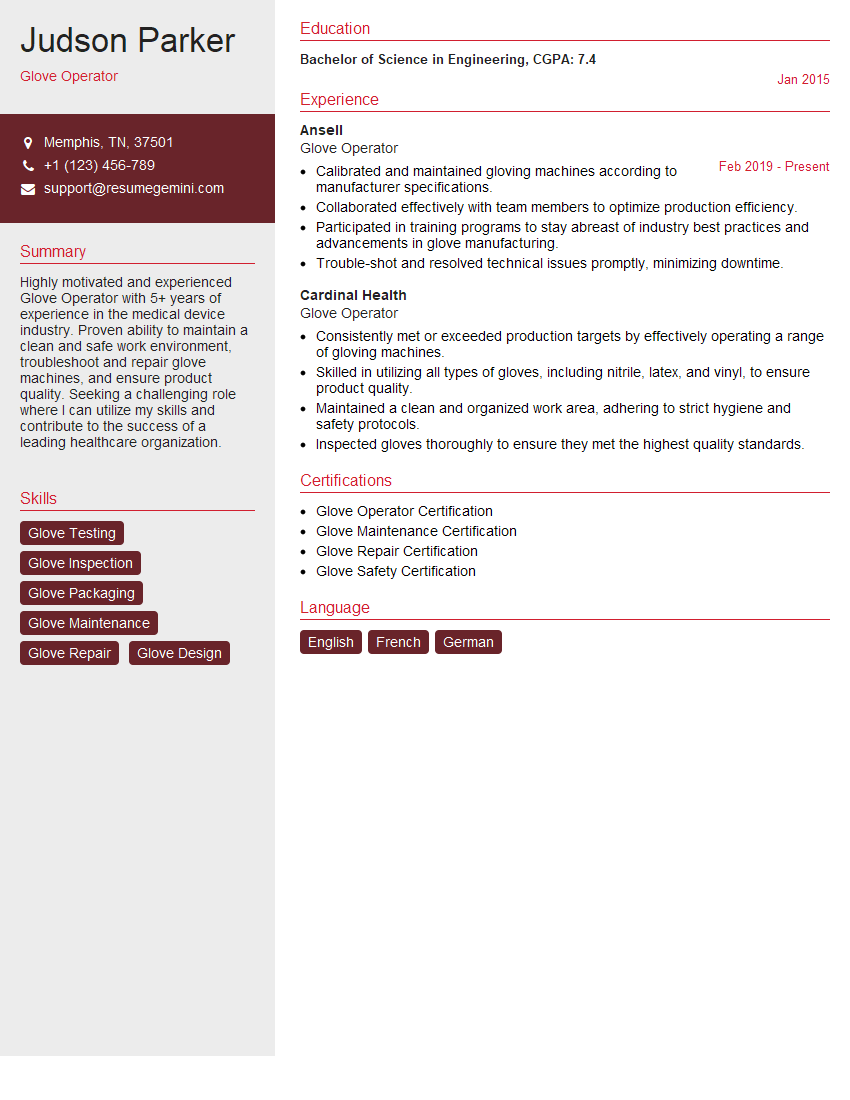

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glove Operator

1. what are the safety precautions taken while operating a glove dipping machine?

The following are the safety precautions typically taken while operating a glove dipping machine:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a mask to protect against chemical exposure.

- Ensure the machine is properly grounded and all electrical connections are secure.

- Inspect the machine before each use for any damage or leaks.

- Do not operate the machine if there are any visible defects or if it is malfunctioning.

- Keep the work area clean and free of debris.

- Do not smoke or eat in the work area.

- Follow all manufacturer’s instructions for safe operation of the machine.

2. what are the different types of gloves that can be produced on a glove dipping machine?

The types of gloves that can be produced on a glove dipping machine include:

- Nitrile gloves

- Latex gloves

- Neoprene gloves

- Vinyl gloves

- Polyurethane gloves

- PVC gloves

3. what are the key factors that affect the quality of gloves produced on a glove dipping machine?

The key factors that affect the quality of gloves produced on a glove dipping machine include:

- The quality of the raw materials used

- The temperature of the dipping bath

- The speed of the dipping process

- The thickness of the glove

- The curing process

4. what are the common problems that can occur during glove dipping and how can they be resolved?

Some common problems that can occur during glove dipping include:

- Holes in the gloves

- Uneven glove thickness

- Discoloration of the gloves

- Bubbles in the gloves

These problems can be resolved by:

- Ensuring that the raw materials are of good quality

- Controlling the temperature of the dipping bath

- Adjusting the speed of the dipping process

- Optimizing the thickness of the glove

- Improving the curing process

5. what are the maintenance procedures that need to be performed on a glove dipping machine?

The maintenance procedures that need to be performed on a glove dipping machine include:

- Regular cleaning and inspection of the machine

- Replacement of worn or damaged parts

- Lubrication of moving parts

- Calibration of the machine

6. what are the safety features of a glove dipping machine?

The safety features of a glove dipping machine include:

- Emergency stop buttons

- Guards to prevent contact with moving parts

- Interlocks to prevent the machine from operating if a guard is open

- Warning labels

7. what is the role of a glove dipping machine operator?

The role of a glove dipping machine operator is to:

- Set up and operate the glove dipping machine

- Monitor the dipping process and make adjustments as needed

- Inspect the gloves for quality

- Package the gloves

- Clean and maintain the machine

8. what are the skills and qualifications required to be a glove dipping machine operator?

The skills and qualifications required to be a glove dipping machine operator include:

- A high school diploma or equivalent

- Experience operating machinery

- Knowledge of quality control procedures

- Ability to work independently and as part of a team

- Strong attention to detail

- Excellent communication skills

9. what is the work environment of a glove dipping machine operator?

The work environment of a glove dipping machine operator is typically a factory setting.

- The work can be repetitive and physically demanding.

- The operator may be exposed to chemicals and fumes.

- The work environment can be noisy.

10. what is the career outlook for glove dipping machine operators?

The career outlook for glove dipping machine operators is expected to be good.

- The demand for gloves is expected to increase in the healthcare, food service, and manufacturing industries.

- As a result, the demand for glove dipping machine operators is expected to increase.

- Glove dipping machine operators with experience and skills can advance to supervisory or management positions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glove Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glove Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Glove Operator, your responsibilities include playing a pivotal role in manufacturing high-quality gloves to satisfy customer requirements and maintaining a safe, efficient work environment. This multifaceted position demands a combination of precision, attention to detail, and technical proficiency to ensure the smooth functioning of the glove production process.

1. Operate Glove Knitting Machines

You will be responsible for operating and monitoring glove knitting machines to produce gloves as per specified designs and quality standards.

- Set up, calibrate, and maintain glove knitting machines to optimize performance and minimize downtime.

- Monitor machine operations, identify potential issues, and take corrective actions to maintain productivity and quality.

2. Inspect Gloves

Ensuring the quality of gloves is paramount. You will meticulously inspect finished gloves to identify and rectify any defects or inconsistencies.

- Conduct thorough visual inspections to assess glove dimensions, shape, and overall appearance.

- Identify and rectify defects such as broken threads, uneven stitching, or material flaws to maintain high quality standards.

3. Package and Label Gloves

After inspection, you will be responsible for packaging and labeling gloves accurately to meet customer specifications and ensure proper inventory management.

- Pack gloves according to specified quantities and packaging requirements.

- Apply labels with product information, including size, style, and any necessary compliance markings.

4. Maintain a Clean and Safe Work Environment

Maintaining a safe and organized work environment is crucial to prevent accidents and ensure the well-being of employees.

- Keep work areas clean and free of debris to minimize tripping hazards and promote a healthy work environment.

- Adhere to established safety protocols, including wearing appropriate protective gear and following proper machine operating procedures.

Interview Tips

Preparing for a Glove Operator interview requires a well-rounded approach that encompasses technical expertise, industry knowledge, and behavioral skills.

1. Research the Company

Take the time to thoroughly research the company you’re applying to. Understand their products, market position, and company culture.

- Visit the company website and social media pages to gather information about their operations and values.

- Read industry news and articles to stay updated on the latest trends and technological advancements in glove manufacturing.

2. Highlight Relevant Skills

Emphasize your technical proficiency in operating glove knitting machines, as well as your experience in inspecting and packaging gloves.

- Quantify your accomplishments whenever possible to demonstrate your impact on previous roles.

- Prepare specific examples of how you improved efficiency, maintained quality standards, or resolved production issues.

3. Demonstrate Attention to Detail

Glove Operators must possess a meticulous eye for detail to ensure product quality. Highlight your ability to identify and rectify even minor defects.

- Share examples of how you have successfully identified and resolved quality issues in previous roles.

- Explain your quality control processes and how you ensure the accuracy and precision of your work.

4. Emphasize Safety and Efficiency

Convey your commitment to maintaining a safe and efficient work environment. Describe your understanding of industry safety protocols and your willingness to adhere to them.

- Highlight your experience in following safety procedures and maintaining a clean and organized work area.

- Explain how you contribute to team safety by identifying potential hazards and taking appropriate actions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glove Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!