Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Glove Sewer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Glove Sewer so you can tailor your answers to impress potential employers.

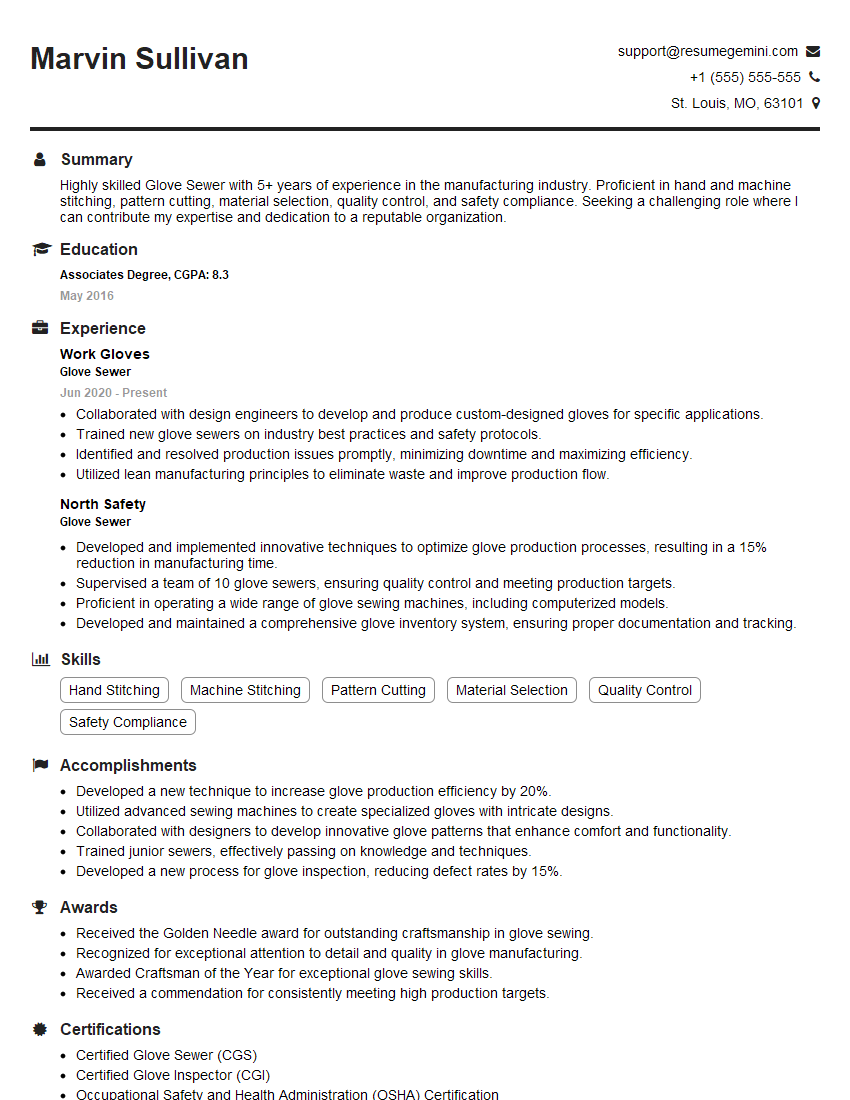

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glove Sewer

1. What are the different types of gloves you have experience sewing?

In my previous role, I gained extensive experience sewing a wide range of gloves, including:

- Leather work gloves

- Nitrile disposable gloves

- Latex surgical gloves

- Kevlar cut-resistant gloves

- Nomex heat-resistant gloves

2. Can you describe the process of sewing a glove from start to finish?

Materials

- Leather or other glove material

- Thread

- Needles

- Sewing machine

Steps

- Cut out the glove pieces from the material.

- Sew the pieces together, starting with the fingers and working your way up to the wrist.

- Reinforce the seams with additional stitching or rivets.

- Add any necessary features, such as Velcro closures or wrist straps.

- Inspect the glove for any defects and make any necessary repairs.

3. What are the most challenging aspects of glove sewing?

The most challenging aspects of glove sewing include:

- Working with delicate materials, such as leather or latex.

- Ensuring that the seams are strong and durable.

- Maintaining precision and accuracy throughout the sewing process.

- Meeting the production deadlines without compromising quality.

- Keeping up with the latest sewing techniques and technologies.

4. What are the quality standards that you must adhere to when sewing gloves?

The quality standards that I must adhere to when sewing gloves include:

- ASTM D3597-15 Standard Specification for Leather Gloves for Industrial Applications

- ANSI/ISEA 105-2016 American National Standard for Hand Protection

- EN 388:2016 European Standard for Protective Gloves Against Mechanical Risks

- ISO 9001:2015 International Standard for Quality Management Systems

- Customer-specific quality requirements

5. What is your experience with using different types of sewing machines?

I have experience using a variety of sewing machines, including:

- Single-needle lockstitch machines

- Double-needle lockstitch machines

- Overlock machines

- Cover stitch machines

- Computerized sewing machines

6. What is your understanding of glove anatomy and how does it inform your sewing process?

My understanding of glove anatomy includes:

- The different parts of the hand and their functions.

- The different types of gloves and their intended uses.

- The ergonomic principles that must be considered when designing and sewing gloves.

This knowledge informs my sewing process by allowing me to:

- Choose the right materials and construction methods for each type of glove.

- Ensure that the gloves fit properly and comfortably.

- Maximize the gloves’ safety and performance.

7. What are the different types of stitches that you use when sewing gloves?

The different types of stitches that I use when sewing gloves include:

- Straight stitch

- Zigzag stitch

- Overlock stitch

- Coverstitch

- Bar tack stitch

8. What are the different types of materials that you use when sewing gloves?

The different types of materials that I use when sewing gloves include:

- Leather

- Nitrile

- Latex

- Kevlar

- Nomex

9. What are the different types of gloves that you have experience sewing?

The different types of gloves that I have experience sewing include:

- Work gloves

- Disposable gloves

- Surgical gloves

- Cut-resistant gloves

- Heat-resistant gloves

10. What are the different types of machines and tools that you use when sewing gloves?

The different types of machines and tools that I use when sewing gloves include:

- Sewing machines

- Overlock machines

- Coverstitch machines

- Cutting machines

- Measuring tools

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glove Sewer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glove Sewer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glove sewers play a crucial role in the manufacturing process, ensuring the production of high-quality gloves for various industries.

1. Assembling Gloves

Glove sewers are responsible for sewing together various pieces of fabric, leather, or other materials to create the desired glove design.

- Select appropriate materials based on glove type and specifications.

- Operate sewing machines to join fabric pieces accurately and securely.

2. Inspecting Gloves

They thoroughly inspect each glove to ensure it meets quality standards, ensuring that only defect-free gloves are shipped to customers.

- Check for proper stitching, seams, and overall workmanship.

- Identify and rectify any defects or imperfections.

3. Maintain Equipment

Glove sewers are expected to maintain their sewing machines and other equipment in good working condition.

- Clean and lubricate machines regularly.

- Troubleshoot and resolve minor equipment issues.

4. Adhere to Safety Protocols

They are responsible for adhering to safety protocols and wearing appropriate personal protective equipment (PPE) while operating sewing machines.

- Follow safety guidelines to prevent accidents and injuries.

- Maintain a clean and organized work area.

Interview Tips

Preparing for a glove sewer interview requires a combination of technical knowledge, attention to detail, and enthusiasm for precision work.

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and reputation. Research the glove industry, including the latest trends and innovations.

- Visit the company’s website.

- Read industry news and articles.

2. Highlight Your Skills and Experience

Focus on showcasing your proficiency in sewing techniques, attention to detail, and ability to meet production targets.

- Quantify your achievements with specific examples.

- Emphasize your experience with different types of materials and glove designs.

3. Demonstrate Your Problem-Solving Abilities

Glove sewers often encounter challenges during the production process. Prepare examples of how you have solved problems and maintained quality standards.

- Describe a time when you identified and resolved a sewing machine issue.

- Explain how you managed to maintain production targets while ensuring accuracy.

4. Emphasize Teamwork and Communication

Glove sewers often work in teams and need to communicate effectively with supervisors and colleagues. Highlight your teamwork skills and ability to follow instructions.

- Share examples of successful collaborations with other team members.

- Explain how you handle feedback and suggestions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glove Sewer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!