Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Glue Clamp Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

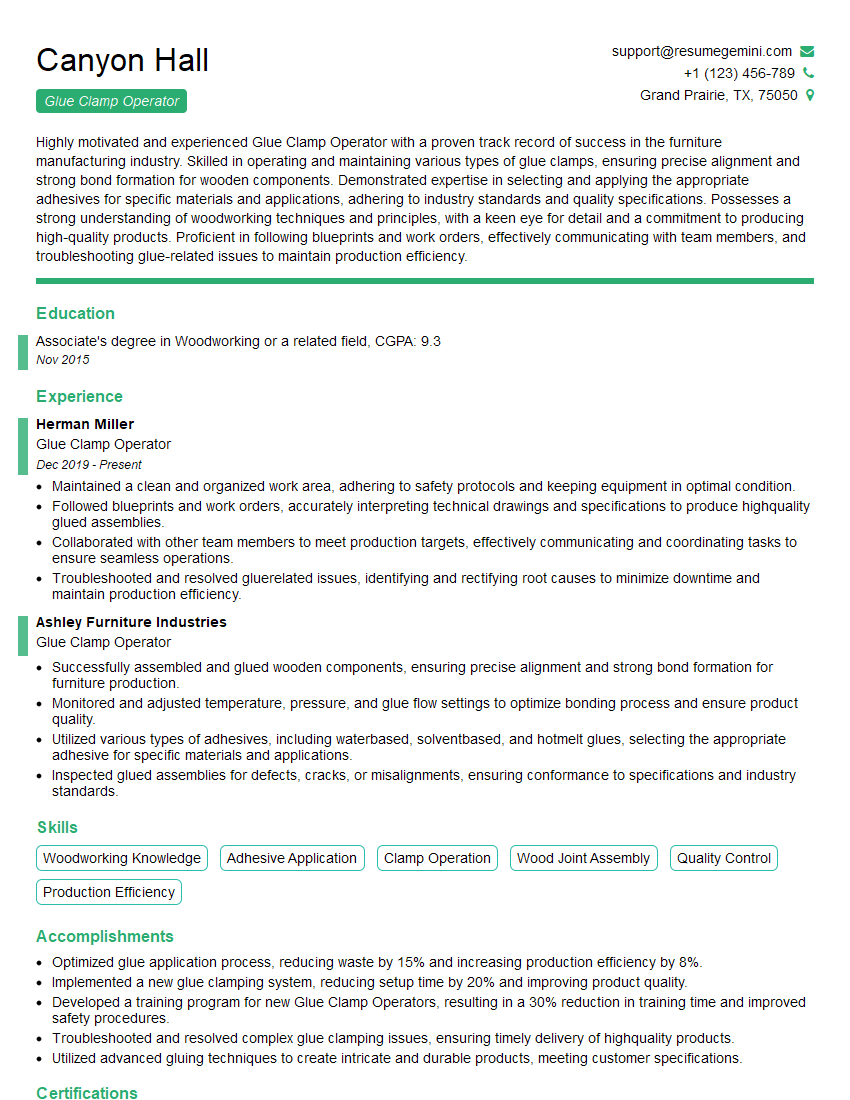

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glue Clamp Operator

1. Describe the steps involved in preparing a glue clamp for operation?

To prepare a glue clamp for operation, I follow these steps:

- Inspect the clamp for any damage or wear.

- Clean the clamp bed and jaws to remove any debris or glue residue.

- Apply a thin layer of glue to the clamp bed.

- Position the workpiece on the clamp bed and align it properly.

- Apply pressure to the workpiece using the clamp handle.

- Check the alignment of the workpiece and make any necessary adjustments.

- Tighten the clamp handle to secure the workpiece in place.

2. How do you determine the correct amount of pressure to apply when clamping wood?

Factors to Consider

- Type of wood

- Thickness of the wood

- Strength of the glue

- Desired bond strength

Determining Pressure

- Start with a low pressure setting and gradually increase it until the glue begins to squeeze out.

- Avoid applying excessive pressure, as this can damage the wood or the glue joint.

- Always refer to the manufacturer’s instructions for the specific glue being used.

3. What are some common problems you have encountered while operating a glue clamp, and how did you resolve them?

- Problem: Glue squeeze-out. Solution: Reduce pressure or extend clamp time.

- Problem: Misaligned workpiece. Solution: Reposition workpiece and adjust clamp settings.

- Problem: Weak glue joint. Solution: Ensure proper glue application, clamping pressure, and cure time.

- Problem: Damaged clamp. Solution: Inspect and repair or replace the damaged part.

4. How do you ensure that the glued joint is properly aligned and secure?

- Use a square or ruler to align the workpiece before clamping.

- Apply even pressure to the workpiece throughout the clamping area.

- Check the alignment of the workpiece periodically during the clamping process.

- Allow the glue to cure fully before removing the clamps.

5. What are the different types of glue clamps, and when would you use each type?

- Bar clamps: General-purpose clamps, suitable for most clamping tasks.

- Pipe clamps: Long, adjustable clamps, ideal for clamping large or irregularly shaped workpieces.

- Mitre clamps: 90-degree clamps, used for joining mitered corners.

- Band clamps: Strap-like clamps, used for wrapping around odd-shaped objects.

- Vacuum clamps: Use vacuum pressure to hold workpieces in place, ideal for delicate or porous materials.

6. What safety precautions should be taken when operating a glue clamp?

- Wear safety glasses to protect eyes from flying debris.

- Keep fingers clear of the clamp jaws and workpiece.

- Do not overload the clamp.

- Use clamps only for their intended purpose.

- Store clamps properly to prevent damage or injury.

7. How do you maintain and calibrate a glue clamp?

Maintenance

- Clean the clamp jaws and bed regularly.

- Lubricate moving parts periodically.

- Inspect the clamp for any damage or wear.

Calibration

- Use a dial gauge or other precision instrument to measure the distance between the clamp jaws.

- Adjust the clamp handle or jaws to achieve the desired gap.

- Recheck the gap and make any necessary adjustments.

8. How do you troubleshoot a glue clamp that is not functioning properly?

- Check for loose or damaged parts.

- Ensure the clamp is properly lubricated.

- Inspect the glue bed and jaws for any debris or glue residue.

- Calibrate the clamp if necessary.

9. What are the benefits of using a glue clamp over other methods of woodworking?

- Provides a secure and evenly distributed hold.

- Ensures proper alignment of workpieces.

- Reduces the risk of movement or shifting during the gluing process.

- Allows for precise control of clamping pressure.

- Improves the overall strength and quality of the glue joint.

10. What are your strengths and weaknesses as a Glue Clamp Operator?

Strengths

- Proficient in operating various types of glue clamps

- Excellent attention to detail and accuracy

- Strong understanding of glue types and their properties

- Ability to work independently and as part of a team

Weaknesses

- Limited experience in working with exotic or specialty woods

- Still developing proficiency in advanced clamping techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glue Clamp Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glue Clamp Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glue Clamp Operators play a vital role in the manufacturing process by operating glue clamp machines to bond materials together. They ensure that the glued materials are properly aligned and held in place until the adhesive dries.

1. Material Handling and Preparation

Handle various types of materials, such as wood, metal, or plastic, to be glued together.

- Inspect materials for defects or damage.

- Prepare materials by cleaning, sanding, or applying primer.

2. Glue Application

Apply glue evenly and precisely to the surfaces to be bonded.

- Select the appropriate type of glue based on the materials being used.

- Adjust glue settings to ensure proper adhesion.

3. Clamping Operations

Operate glue clamp machines to hold materials together while the glue dries.

- Set up and operate various types of glue clamps, such as hydraulic, pneumatic, or manual clamps.

- Adjust clamping pressure and duration to achieve optimal bond strength.

4. Quality Control

Inspect glued assemblies to ensure proper alignment and adhesion.

- Identify and resolve any defects or imperfections in the glued joints.

- Conduct quality control checks to maintain high standards of production.

Interview Tips

Preparation is key to acing any interview. Here are a few tips to help you stand out as a Glue Clamp Operator candidate:

1. Research the Company and Position

Take the time to learn about the company you’re applying to and the specific role you’re interviewing for. This will help you tailor your answers and show that you’re genuinely interested in the opportunity.

- Visit the company website to learn about their products, services, and culture.

- Read industry news and articles to stay up-to-date on the latest trends in manufacturing.

2. Practice Your Answers

Once you’ve done your research, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Think about your experience and how it relates to the job requirements.

- Prepare specific examples of your skills and accomplishments.

3. Dress Professionally

First impressions matter, so make sure you dress appropriately for the interview. Business casual attire is usually a good choice.

- Wear clean, pressed clothing that fits well.

- Avoid wearing clothes that are too revealing or too casual.

4. Be Enthusiastic and Positive

Employers want to hire people who are passionate about their work. Show the interviewer that you’re excited about the opportunity to work as a Glue Clamp Operator.

- Smile, make eye contact, and speak clearly.

- Be enthusiastic about your skills and experience.

Next Step:

Now that you’re armed with the knowledge of Glue Clamp Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Glue Clamp Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini