Are you gearing up for an interview for a Glue Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Glue Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

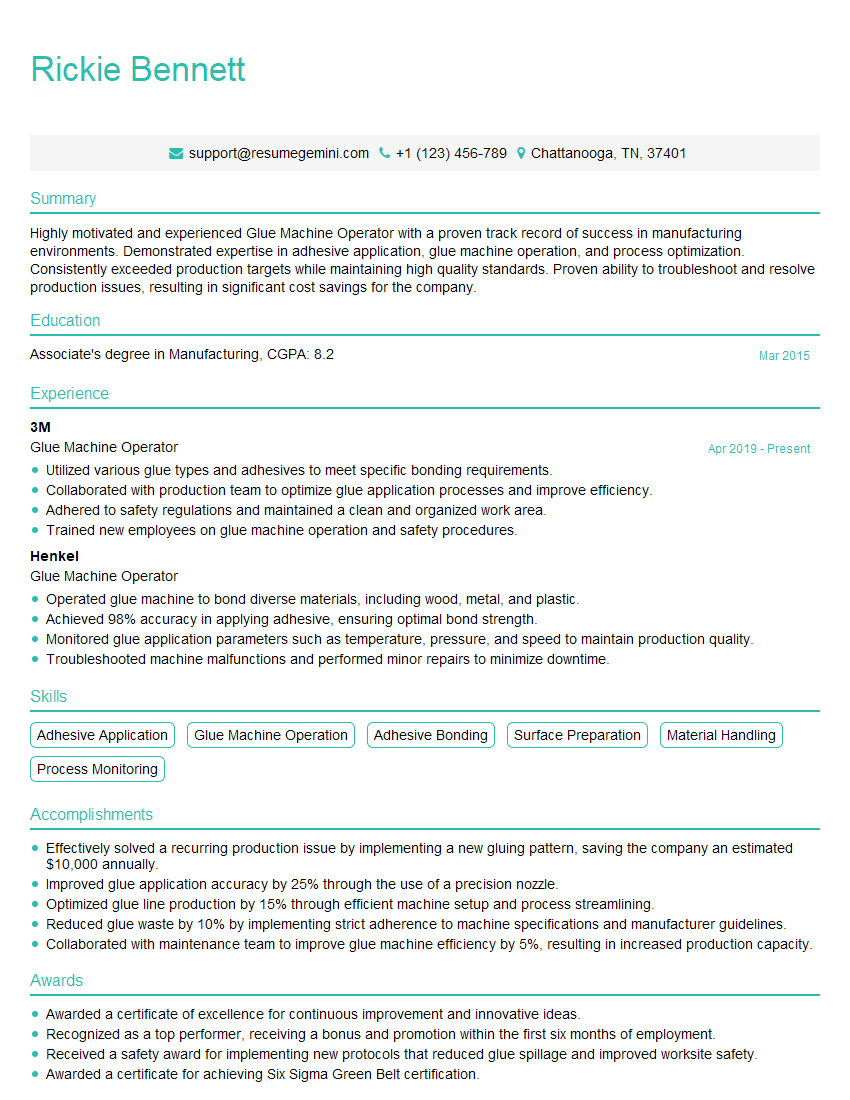

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glue Machine Operator

1. What are the different types of glue machines and their applications?

There are several types of glue machines, each designed for specific applications. Some common types include:

- Hot melt glue machines: These machines use solid glue sticks that are melted to form a strong bond. They are ideal for packaging, bookbinding, and woodworking.

- Cold glue machines: These machines use liquid glue that is applied directly to the surfaces being bonded. They are commonly used in manufacturing, construction, and paper production.

- Solvent-based glue machines: These machines use glue that is dissolved in a solvent. They create a permanent bond that is resistant to heat and moisture. They are often used in aerospace and automotive applications.

- Two-component glue machines: These machines use two separate components that are mixed together to form a strong adhesive. They are commonly used in construction and metalworking.

2. What are the key factors to consider when selecting a glue machine?

Factors to consider:

- Type of glue: The type of glue used will determine the machine’s capabilities and limitations.

- Application requirements: The specific application will influence the machine’s size, speed, and other features.

- Materials being bonded: The materials being bonded will determine the type of glue and machine required.

- Production volume: The production volume will determine the machine’s capacity and speed.

- Budget: The budget available will limit the range of machines that can be considered.

3. How do you troubleshoot common problems with glue machines?

Troubleshooting glue machines requires identifying the symptoms of the problem and taking appropriate steps to resolve it. Common problems and their solutions include:

- Clogged nozzles: This can be caused by dried glue or other debris. The nozzle can be cleaned using a solvent or compressed air.

- Poor bonding: This can be caused by insufficient glue application, incorrect glue type, or improper surface preparation. The correct glue should be used, and the surfaces should be cleaned and dried before bonding.

- Uneven glue application: This can be caused by a faulty glue gun or applicator. The equipment should be checked and repaired or replaced if necessary.

- Glue leakage: This can be caused by a loose or damaged hose or fitting. The hose and fittings should be inspected and tightened or replaced as needed.

4. What are the safety precautions to follow when operating a glue machine?

Safety precautions to follow when operating a glue machine include:

- Wear appropriate safety gear, including gloves, safety glasses, and a respirator if necessary.

- Keep the work area clean and well-ventilated to prevent glue fumes from accumulating.

- Follow the manufacturer’s instructions for operating the machine safely.

- Do not touch or come into contact with hot glue, as it can cause burns.

- Store glue and solvents safely away from heat and ignition sources.

5. What maintenance procedures are required for glue machines?

Regular maintenance is crucial to ensure optimal performance and longevity of glue machines. Maintenance procedures include:

- Daily cleaning: The machine should be cleaned daily to remove any glue residue or debris.

- Regular lubrication: Moving parts of the machine should be lubricated regularly according to the manufacturer’s instructions.

- Periodic inspections: The machine should be inspected periodically for any signs of wear or damage. Loose parts should be tightened, and damaged parts should be replaced.

- Calibration: The machine should be calibrated regularly to ensure accurate glue application.

6. How do you ensure the quality of glued joints?

Ensuring the quality of glued joints requires attention to several factors, including:

- Proper surface preparation: The surfaces being bonded should be clean, dry, and free of any contaminants.

- Correct glue type: The type of glue used should be appropriate for the materials being bonded and the application.

- Adequate glue application: Sufficient glue should be applied to ensure a strong bond, but not so much that it creates a mess.

- Proper curing time: The glue should be allowed to cure fully before the joint is subjected to any stress.

7. What are the different types of adhesives used in the manufacturing industry?

Various adhesives are used in the manufacturing industry, each with its own properties and applications, including:

- Epoxy: A strong and durable adhesive used for bonding metals, plastics, and composites.

- Cyanoacrylate (super glue): A fast-acting adhesive used for bonding a wide range of materials, including plastics, metal, and rubber.

- Polyurethane: A versatile adhesive used for bonding wood, metal, and composites, providing excellent resistance to moisture.

- Hot melt: A thermoplastic adhesive that is heated to a liquid state before application and solidifies upon cooling.

- Pressure-sensitive: An adhesive that forms a bond when pressure is applied, commonly used in tapes and labels.

8. How do you calculate the amount of adhesive required for a specific application?

Calculating the amount of adhesive required depends on the following factors:

- Surface area: The area of the surfaces being bonded.

- Coverage rate: The amount of adhesive needed to cover a unit area, typically specified by the adhesive manufacturer.

- Bond thickness: The desired thickness of the adhesive layer.

Formula:

Adhesive Amount = Surface Area x Coverage Rate x Bond Thickness

9. What techniques are used to improve the bond strength of adhesives?

Several techniques can be employed to enhance the bond strength of adhesives, including:

- Surface preparation: Cleaning and roughening the surfaces being bonded improves adhesion.

- Primer application: Using a primer can create a better bond between the adhesive and the substrate.

- Clamping: Applying pressure to the bonded joint during curing helps improve bond strength.

- Curing conditions: Following the manufacturer’s instructions regarding temperature, humidity, and curing time is crucial.

10. What are the potential health hazards associated with working with adhesives?

Working with adhesives can pose certain health hazards, including:

- Skin irritation: Contact with some adhesives can cause skin irritation or allergic reactions.

- Respiratory issues: Inhalation of adhesive fumes can lead to respiratory problems, such as asthma or bronchitis.

- Eye damage: Contact with adhesives can cause eye irritation or damage if not handled properly.

Precautions:

To mitigate these hazards, it’s important to:

- Wear appropriate personal protective equipment, such as gloves, respirators, and safety glasses.

- Work in well-ventilated areas.

- Handle adhesives according to the manufacturer’s instructions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glue Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glue Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glue Machine Operators are responsible for the operation and maintenance of glue machines used in the manufacturing process.

1. Operating Glue Machines

Operate glue machines to apply glue to materials.

- Set up and adjust glue machines according to specifications.

- Monitor glue machine operation and make adjustments as needed.

2. Maintenance

Perform routine maintenance on glue machines.

- Clean and lubricate glue machines.

- Inspect glue machines for wear and tear.

3. Quality Control

Inspect glued materials for quality.

- Identify and correct any defects in glued materials.

- Maintain records of glue machine operation and quality control.

4. Safety

Follow all safety procedures related to the operation of glue machines.

- Wear appropriate safety gear, such as gloves and eye protection.

- Operate glue machines in a well-ventilated area.

Interview Tips

Interviewing for a Glue Machine Operator position requires preparation and knowledge of the job’s responsibilities and the company’s culture.

1. Research the Company and Position

Research the company’s website, social media pages, and industry news to gain insights into their values, mission, and current projects. This will help you understand the company’s culture and how the Glue Machine Operator role fits into their operations.

- Identify the key responsibilities of the Glue Machine Operator role and tailor your answers to highlight your relevant skills and experience.

- Practice answering common interview questions, such as “Why are you interested in this role?” and “What are your strengths and weaknesses?”

2. Prepare Examples of Your Work

Be prepared to provide specific examples of your experience operating and maintaining glue machines. This could include describing a time you solved a problem with a glue machine or implemented a new process that improved efficiency.

- Quantify your accomplishments whenever possible using specific metrics or data.

- Use the STAR method (Situation, Task, Action, Result) to структурировать Your answers.

3. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. This shows that you respect the company and the interviewer’s time.

- Choose clothing that is clean, pressed, and appropriate for an office setting.

- Plan your route and give yourself plenty of time to get to the interview location.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest in the role and the company. It also gives you an opportunity to learn more about the organization and the position.

- Prepare questions that are specific to the Glue Machine Operator role and the company’s industry.

- Avoid asking generic questions that can be easily answered by researching the company online.

5. Follow Up After the Interview

Within 24 hours of the interview, send a thank-you email to the interviewer. This is an opportunity to reiterate your interest in the role and thank the interviewer for their time.

- Reiterate your key qualifications and how you believe you can contribute to the company.

- If you have any additional questions or information to share, include it in your email.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glue Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!