Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Glue Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Glue Maker so you can tailor your answers to impress potential employers.

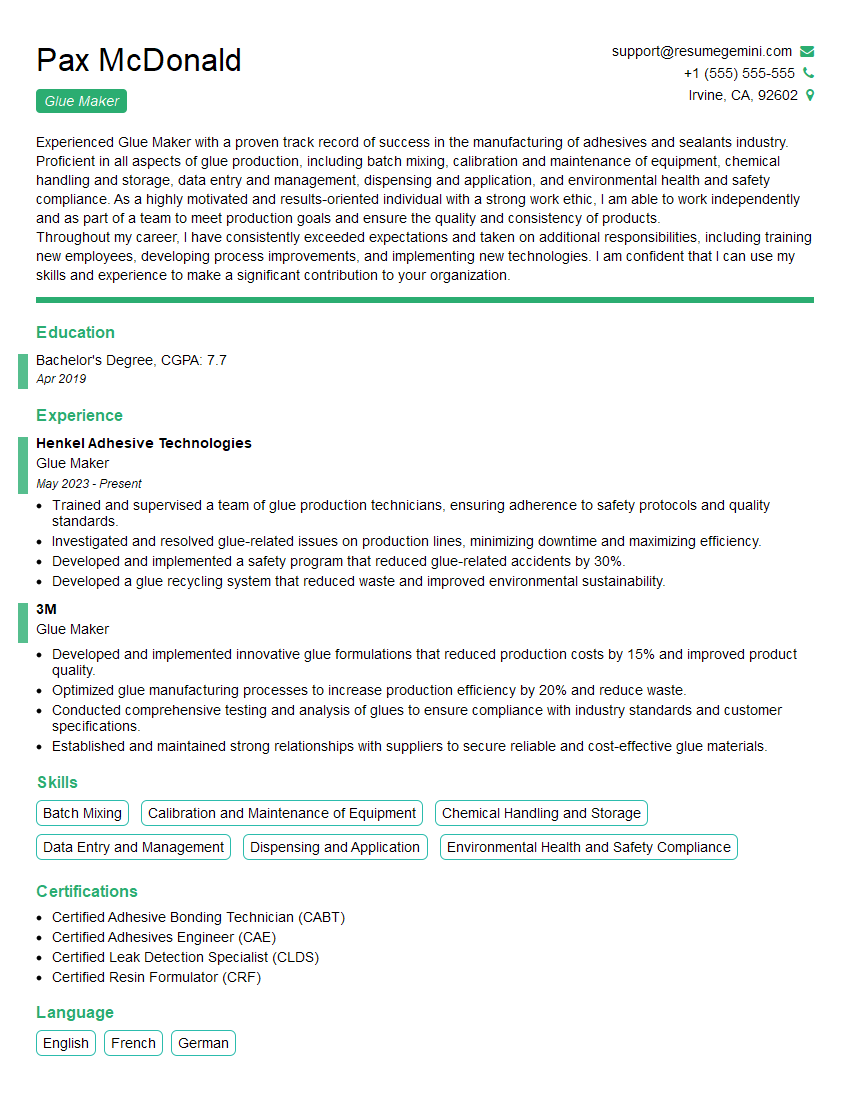

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glue Maker

1. What are the different types of glues and their applications?

- Animal Glue: It is a natural glue made from animal collagen and used in woodworking, bookbinding, and paper products.

- Hide Glue: A stronger version of animal glue, it is used in furniture making and musical instrument construction.

- Polyvinyl Acetate (PVA) Glue: Commonly known as white glue, it is used for general-purpose bonding in woodworking, paper crafts, and construction.

- Cyanoacrylate Glue: Superglue, known for its fast bonding time, is used for small repairs and bonding non-porous materials.

- Epoxy Glue: A strong and durable glue, it is used in metalworking, electronics, and marine applications.

2. How do you determine the appropriate glue for a specific application?

Factors to Consider:

- Type of materials being bonded

- Strength and durability requirements

- Working time and curing time

- Environmental conditions (e.g., temperature, moisture)

Process:

- Identify the materials and their properties.

- Assess the strength and durability needed.

- Consider the environment where the bond will be used.

- Consult technical data sheets or seek expert advice.

3. What are the key ingredients and the manufacturing process of animal glue?

- Ingredients: Animal hides and bones, water, lime

- Process:

- Soak hides in lime to remove hair and impurities.

- Boil hides and bones to extract collagen.

- Filter and clarify the gelatin solution.

- Cool and dry the gelatin to form solid glue.

4. Explain the advantages and disadvantages of using epoxy glue.

Advantages:

- Exceptional strength and durability

- Excellent adhesion to various materials

- Resistant to moisture and chemicals

Disadvantages:

- Long curing time

- Requires careful mixing of components

- Can be brittle and prone to cracking

5. Describe the safety precautions that must be taken when working with cyanoacrylate glue.

- Wear gloves and eye protection.

- Work in a well-ventilated area.

- Avoid skin contact, as it can cause irritation and burns.

- If contact occurs, wash the affected area immediately with soap and water.

- Do not ingest or inhale cyanoacrylate glue.

6. What are the common defects that can occur in glue joints, and how can they be prevented?

- Starvation: Occurs when there is insufficient glue applied, resulting in a weak bond. Prevention: Ensure proper glue coverage.

- Joint Misalignment: When parts are not aligned correctly, leading to uneven stress distribution. Prevention: Use clamps or jigs to hold parts in place.

- Contamination: Impurities on surfaces can prevent proper bonding. Prevention: Clean and dry surfaces before gluing.

- Over-Clamping: Excessive clamping pressure can squeeze out the glue, weakening the bond. Prevention: Apply just enough pressure to hold parts together.

- Premature Loading: Applying stress on a joint before it has fully cured can result in failure. Prevention: Allow sufficient curing time before handling or using the glued item.

7. Explain the role of crosslinking agents in the production of epoxy glue.

- Crosslinking agents react with the epoxy resin to form a network of bonds.

- This network strengthens the glue, improves its durability, and reduces shrinkage.

- Common crosslinking agents include amines, amides, and acids.

- The type and amount of crosslinking agent used can influence the properties of the epoxy glue.

8. Discuss the advancements in glue technology and emerging applications.

- Bio-based Adhesives: Environmentally friendly glues made from renewable resources.

- Conductive Adhesives: Used in electronic devices and printed circuit boards.

- Nanotechnology in Adhesives: Enhanced properties such as increased strength, durability, and self-healing abilities.

- 3D Printing Adhesives: Specially formulated glues for bonding 3D printed materials.

- Medical Adhesives: Used in surgical procedures and wound closures.

9. What are the quality control measures implemented in glue manufacturing?

- Raw Material Inspection: Verifying the quality and consistency of glue ingredients.

- In-Process Testing: Monitoring glue properties during the manufacturing process.

- Finished Product Testing: Evaluating the strength, durability, and other performance criteria of manufactured glue.

- Statistical Process Control: Using statistical tools to monitor and improve production processes.

- Compliance with Standards: Adhering to industry standards and regulations for glue quality.

10. Describe a situation where you successfully resolved a customer complaint related to glue performance.

- Empathetic Response: Listened attentively to the customer’s concerns.

- Technical Analysis: Investigated the issue, testing the glue and examining the application.

- Root Cause Identification: Determined that the glue was not suitable for the specific material or environmental conditions.

- Alternative Recommendation: Suggested an alternative glue that met the customer’s requirements.

- Follow-Up: Monitored the customer’s experience with the new glue to ensure satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glue Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glue Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Glue Maker is responsible for mixing and preparing adhesives, resins, and other bonding materials, which are vital components in various industries. Some key job responsibilities include but are not limited to:

1. Formulation and Mixing

Reading and understanding provided formulas to accurately mix and prepare adhesives or resins by following established procedures.

2. Quality Control

Performing quality control checks on produced adhesives to ensure their compliance with specified standards.

3. Equipment Maintenance

Maintaining and cleaning assigned equipment such as blenders, tanks, and filling machines, and reporting any issues promptly.

4. Inventory Management

Maintaining inventory levels for raw materials and finished products, ensuring timely procurement and storage.

Interview Tips

1. Research the Company and Role

- Familiarize yourself with the specific industry, company, and job requirements.

- Research common interview questions and prepare thoughtful responses.

2. Highlight Relevant Experience and Skills

- Emphasize past experience in manufacturing, mixing, or quality control, especially in the adhesives or chemicals industry.

- Showcase your understanding of chemistry, safety protocols, and equipment handling.

3. Practice Communication and Presentation

- Prepare clear and concise answers to potential interview questions.

- Practice your communication skills to articulate your ideas and respond confidently.

4. Be Enthusiastic and Professional

- Demonstrate your passion for the role and the industry.

- Maintain a professional demeanor throughout the interview, making eye contact and asking insightful questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glue Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.