Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Glue Size Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

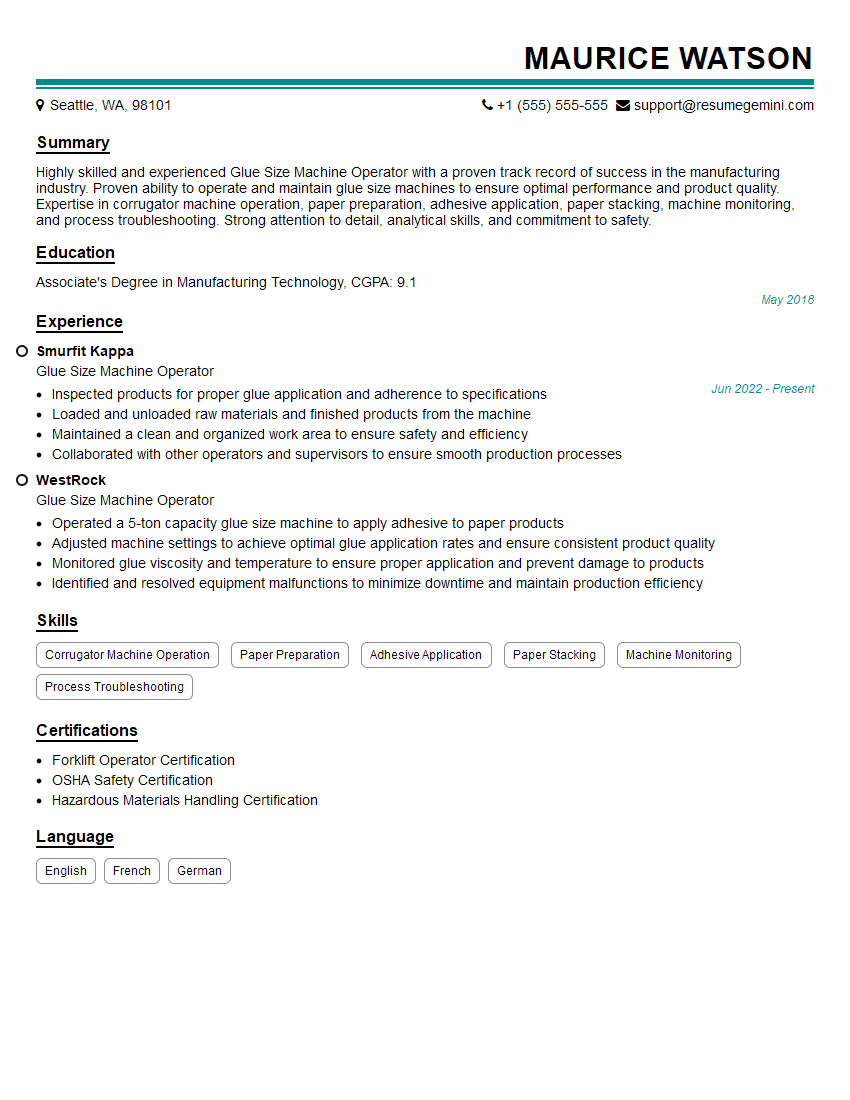

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glue Size Machine Operator

1. What are the key responsibilities of a Glue Size Machine Operator?

As a Glue Size Machine Operator, I am responsible for operating, maintaining, and repairing glue size machines used in the papermaking process. My duties include:

- Monitoring machine operation, ensuring smooth and efficient production

- Adjusting machine settings to control glue size viscosity, temperature, and application rate

- Performing routine maintenance and repairs to minimize downtime and maximize machine uptime

- Maintaining a clean and safe work environment, adhering to safety protocols

2. Describe the process of preparing glue solution for the machine.

To prepare glue solution for the machine, I follow these steps:

Weighing and Mixing

- Weigh the required amount of adhesive powder

- Add the powder to a mixing tank and gradually add water while mixing

- Thoroughly mix the solution to achieve a homogeneous consistency and desired viscosity

Heating and Cooking

- Heat the solution while continuously stirring to prevent lump formation

- Cook the solution at the specified temperature for the required time

- Monitor the solution’s viscosity and make adjustments as needed

Testing and Adjustment

- Test the glue solution’s viscosity and pH level to meet the desired specifications

- Make adjustments to the solution’s composition or cooking time as necessary

3. What are the common problems that can occur during glue size machine operation and how do you troubleshoot them?

Common problems during glue size machine operation include:

- Uneven glue application: Adjust machine settings, check nozzle alignment, and clean nozzles

- Insufficient glue adhesion: Inspect glue quality, check glue viscosity, and adjust machine settings

- Mechanical failures: Identify the source of the failure, perform maintenance or repairs, and replace defective parts

- Corrosion: Clean and lubricate machine components, apply anti-corrosion coatings, and maintain proper ventilation

- Safety hazards: Ensure proper machine guarding, wear personal protective equipment, and follow safety protocols

4. How do you maintain the quality of the glue size product?

To maintain glue size product quality, I adhere to the following practices:

- Using high-quality raw materials and following established recipes

- Monitoring machine operation and adjusting settings to ensure consistent product characteristics

- Performing regular quality checks on glue viscosity, pH level, and other parameters

- Maintaining a clean and sanitized environment to prevent contamination

- Documenting all production and quality control activities for traceability

5. Describe the safety measures you observe while operating a glue size machine.

Safety is paramount when operating a glue size machine. I follow these measures:

- Wearing appropriate personal protective equipment (PPE), including gloves, apron, and safety glasses

- Ensuring machine guards are in place and operational

- Handling chemicals and adhesives safely, following established protocols

- Maintaining a clean and organized work area, free from tripping hazards and spills

- Reporting any safety concerns or accidents promptly

6. What are the different types of glue used in the papermaking process, and how do their properties affect the final product?

Common types of glue used in papermaking include:

- Animal glue: Provides high bonding strength, flexibility, and resistance to moisture

- Starch glue: Derived from plant sources, offers good adhesion and cost-effectiveness

- Synthetic glue: Engineered polymers with tailored properties, providing specific performance characteristics

- Acrylic glue: Fast-drying, strong, and versatile, used for packaging and specialty applications

- Silicone glue: Resistant to moisture, heat, and chemicals, used in high-performance applications

7. How do you measure and control glue viscosity to ensure optimal machine performance?

Glue viscosity is crucial for proper machine operation. I measure and control it using the following methods:

- Viscometer: A device that measures fluid viscosity by measuring the resistance to flow

- Falling ball viscometer: A simple method using a ball dropped into the glue solution to determine viscosity

- Brookfield viscometer: A rotational viscometer that provides accurate viscosity measurements

- Online viscosity sensors: Installed on the machine to provide real-time viscosity monitoring

- Adjusting glue solution parameters: Viscosity can be adjusted by varying temperature, concentration, or adding modifiers

8. What is the importance of calibrating glue size machine sensors, and how often should it be done?

Calibrating sensors is essential for accurate machine operation and product quality. I adhere to the following practices:

- Regular calibration ensures sensors provide reliable and consistent measurements

- Calibrating sensors reduces the risk of production errors and product defects

- Frequency of calibration depends on factors such as machine usage, environmental conditions, and manufacturer recommendations

- Establish a regular calibration schedule to maintain sensor accuracy and minimize downtime

- Use certified calibration equipment and follow established calibration procedures

9. How do you handle and store chemicals used in the glue size process to ensure safety and efficiency?

Safe and efficient chemical handling is crucial. I follow these practices:

- Proper storage of chemicals in designated, well-ventilated areas

- Using appropriate containers and equipment for handling and transportation

- Wearing personal protective equipment (PPE) during handling operations

- Following established safety protocols, including spill containment and disposal procedures

- Maintaining a clean and organized storage area to minimize hazards

10. What are your strategies for reducing waste and improving the efficiency of the glue size process?

Waste reduction and efficiency improvement are priorities for me. I employ the following strategies:

- Optimizing glue recipe and application to minimize excess glue usage

- Regular machine maintenance to prevent leaks and minimize wastage

- Implementing automated processes to reduce manual intervention and improve accuracy

- Monitoring production data to identify and address areas of inefficiency

- Training operators on best practices for efficient glue size application

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glue Size Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glue Size Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glue Size Machine Operators are responsible for the operation and maintenance of glue size machines, which are used to apply glue to paper and other materials. They ensure the smooth and efficient operation of the machines, and monitor the quality of the finished product.

1. Machine Operation

Operate glue size machines to apply glue to paper, cardboard, or other materials.

- Set up and adjust the machine according to the specifications of the job.

- Monitor the machine during operation and make adjustments as needed.

2. Quality Control

Inspect the finished product to ensure that it meets the required quality standards.

- Check the thickness and uniformity of the glue application.

- Identify and correct any defects in the finished product.

3. Machine Maintenance

Perform basic maintenance on the glue size machine.

- Clean and lubricate the machine according to the manufacturer’s instructions.

- Replace worn or damaged parts as needed.

4. Safety

Follow all safety regulations and procedures.

- Wear appropriate personal protective equipment (PPE).

- Keep the work area clean and free of hazards.

Interview Tips

Preparing for an interview can be daunting, but with the right strategies, you can increase your chances of success. Here are some tips to help you ace your interview for a Glue Size Machine Operator position:

1. Research the Company and the Role

Before you go into the interview, take some time to research the company and the specific role you are applying for. This will help you understand the company’s culture, goals, and the requirements of the job. You can find information on the company’s website, LinkedIn, or other online resources.

- Practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Be able to talk about your experience and skills. Be prepared to give specific examples of how you have used your skills in the past.

2. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for an office setting. Avoid wearing anything too revealing or casual.

- Arrive on time for your interview. Punctuality shows that you are respectful of the interviewer’s time.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

3. Be Enthusiastic and Positive

Hiring managers want to hire people who are enthusiastic and positive about their work. Show the interviewer that you are excited about the opportunity to work at the company and that you are confident in your abilities.

- Be prepared to answer questions about your experience and skills.

- Be able to talk about your goals and how they align with the company’s goals.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the company and the role. This shows that you are interested in the position and that you are taking the interview seriously.

- Thank the interviewer for their time and consideration.

- Follow up with the interviewer after the interview to reiterate your interest in the position and to thank them again for their time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Glue Size Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Glue Size Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.