Are you gearing up for a career in Glue Spreading Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Glue Spreading Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

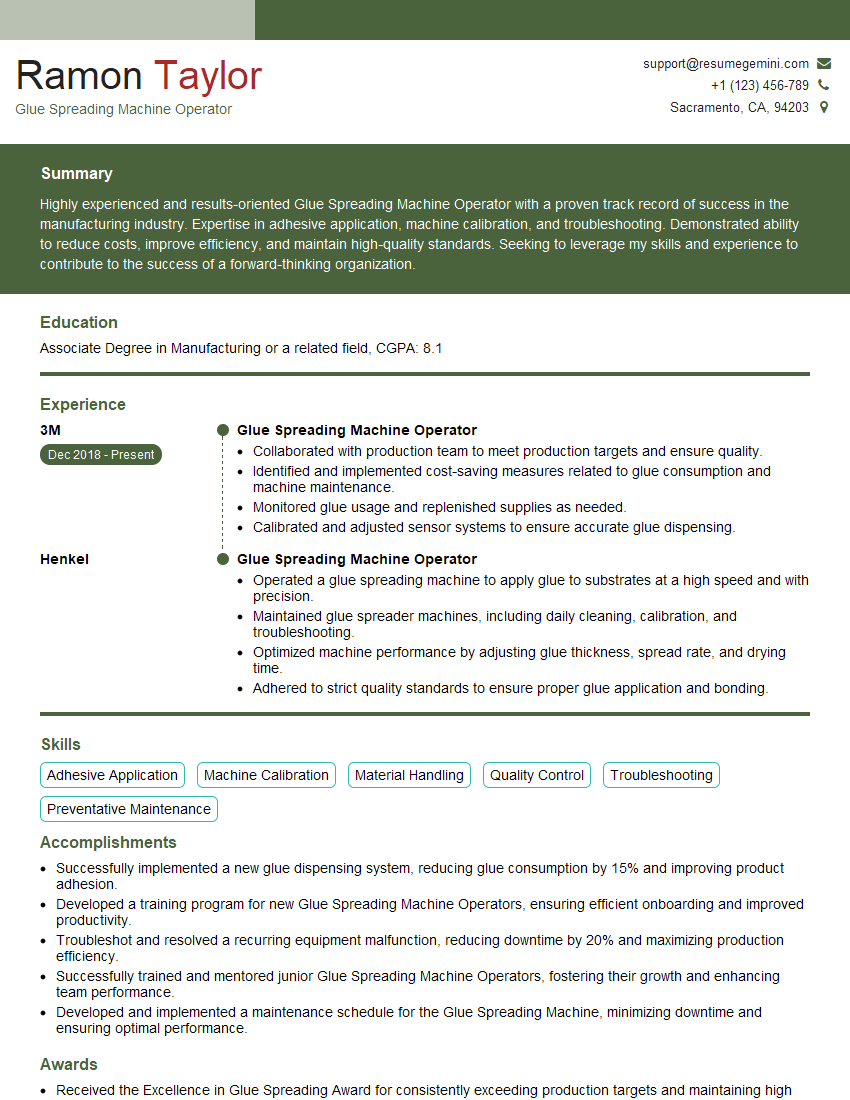

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glue Spreading Machine Operator

1. What are the key responsibilities of a Glue Spreading Machine Operator?

- Monitoring and operating a glue spreading machine to apply adhesive to various materials.

- Maintaining machine settings and ensuring that the glue is applied evenly and consistently.

- Inspecting materials before and after gluing to ensure quality control.

- Loading and unloading materials from the machine efficiently.

- Performing regular maintenance and troubleshooting tasks to keep the machine running smoothly.

2. What types of adhesives are commonly used in glue spreading machines?

Water-based adhesives

- Pros: Non-toxic, easy to clean up, cost-effective.

- Cons: Less water-resistant, shorter shelf life.

Solvent-based adhesives

- Pros: Strong bonding, quick drying.

- Cons: Flammable, toxic fumes, more expensive.

Hot melt adhesives

- Pros: Fast setting, high bond strength, versatile.

- Cons: High temperature required, potential for burns.

3. What factors should be considered when selecting the appropriate adhesive for a particular application?

- Type of materials being bonded.

- Desired bond strength and durability.

- Environmental conditions (e.g., temperature, humidity).

- Production speed and efficiency requirements.

- Health and safety considerations.

4. What are the common causes of glue spreading problems and how can they be resolved?

- Insufficient glue application: Check glue supply, adjust machine settings, clean glue nozzles.

- Uneven glue distribution: Check roller alignment, adjust spreader gap, replace worn rollers.

- Glue stringing or dripping: Reduce glue viscosity, adjust machine speed, check for leaks.

- Material sticking to the rollers: Clean rollers regularly, apply release agent, adjust roller pressure.

- Excessive glue penetration: Use a less penetrating adhesive, adjust roller pressure, increase material thickness.

5. Describe the safety precautions that should be followed when operating a glue spreading machine.

- Wear appropriate PPE (e.g., gloves, safety glasses, apron).

- Keep work area clean and well-ventilated.

- Handle chemicals safely (e.g., adhesives, solvents).

- Follow manufacturer’s instructions for machine operation and maintenance.

- Be aware of potential hazards (e.g., moving parts, electrical wires).

6. What are the key performance indicators (KPIs) used to measure the effectiveness of a Glue Spreading Machine Operator?

- Machine uptime and efficiency.

- Glue application quality and consistency.

- Material defect rate.

- Productivity (e.g., materials processed per hour).

- Compliance with safety regulations.

7. What maintenance tasks are typically performed on a glue spreading machine?

- Cleaning and lubricating machine components.

- Inspecting and replacing worn parts (e.g., rollers, nozzles).

- Calibrating machine settings.

- Troubleshooting and resolving machine malfunctions.

- Performing preventive maintenance to minimize downtime.

8. Explain the role of automation in modern glue spreading machines.

- Improved accuracy and consistency of glue application.

- Reduced labor costs and increased production efficiency.

- Enhanced quality control through automated monitoring systems.

- Remote monitoring and control capabilities.

- Reduced waste and environmental impact.

9. Describe the different gluing techniques used in various industries.

- Contact adhesion: Adhesive is applied to both surfaces and pressed together.

- Pressure-sensitive adhesion: Adhesive sticks to surfaces upon application of pressure.

- Heat-activated adhesion: Adhesive requires heat to activate bonding.

- Ultraviolet (UV) curing: Adhesive is cured using UV light.

- Radio frequency (RF) curing: Adhesive is cured using RF energy.

10. Discuss the latest advancements in glue spreading technology and their potential impact on the industry.

- Laser-guided glue application: Increased precision and reduced waste.

- Nanotechnology-based adhesives: Enhanced bonding strength and durability.

- Biodegradable and sustainable adhesives: Reduced environmental impact.

- Artificial intelligence (AI)-powered machines: Optimized performance and predictive maintenance.

- Cloud-based data analytics: Improved quality control and process optimization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glue Spreading Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glue Spreading Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Glue Spreading Machine Operator is responsible for operating and maintaining glue spreading machines in a variety of industrial settings. Key responsibilities include:

1. Machine Operation

Operate glue spreading machines to apply glue to various materials, such as paper, fabric, and wood.

- Adjust machine settings to ensure proper glue application.

- Monitor machine operation and make adjustments as needed to maintain optimal performance.

2. Machine Maintenance

Perform routine maintenance on glue spreading machines to ensure optimal performance and prevent breakdowns.

- Clean and lubricate machine components.

- Inspect machines for wear and tear, and replace or repair defective parts as needed.

3. Material Handling

Handle materials safely and efficiently, ensuring that materials are properly loaded and unloaded from the machine.

- Load and unload materials from the glue spreading machine.

- Inspect materials for defects before loading them onto the machine.

4. Quality Control

Conduct quality checks on glued products to ensure that they meet specifications.

- Inspect glued products for defects, such as uneven glue application or improper bonding.

- Take corrective action as needed to ensure that products meet quality standards.

Interview Tips

To prepare for an interview for a Glue Spreading Machine Operator position, it is important to:

1. Research the Company and Position

Research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific responsibilities and expectations of the role.

- Visit the company’s website to learn about their history, products or services, and recent news.

- Read the job description carefully to identify the key requirements and qualifications for the position.

2. Practice Your Answers to Common Interview Questions

Practice answering common interview questions that are likely to be asked, such as:

- Tell me about yourself and your experience.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- How do you handle working under pressure?

- What are your salary expectations?

3. Highlight Your Relevant Skills and Experience

In your interview, be sure to highlight your relevant skills and experience that make you a good fit for the position. For example, you could discuss your experience operating and maintaining glue spreading machines, your knowledge of different types of glue and their applications, and your commitment to quality control.

- Use specific examples to illustrate your skills and experience.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

4. Be Enthusiastic and Professional

Be enthusiastic and professional throughout the interview. This will show the interviewer that you are interested in the position and that you are eager to learn more about the company.

- Make eye contact with the interviewer and speak clearly and confidently.

- Dress appropriately for the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glue Spreading Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!