Are you gearing up for a career in Glueline Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Glueline Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

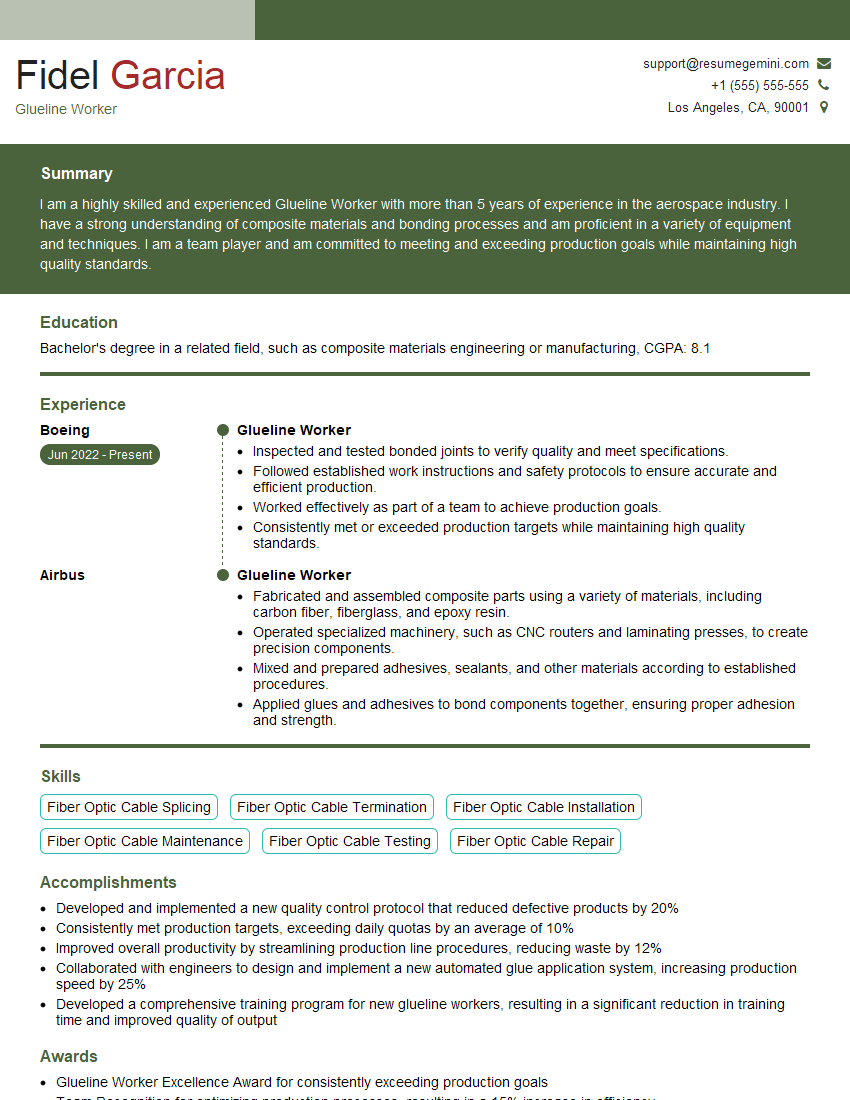

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glueline Worker

1. What are the key responsibilities of a Glueline Worker?

The primary responsibilities of a Glueline Worker typically include:

- Operating and monitoring glueline machines to apply adhesives to surfaces

- Inspecting products for defects and ensuring quality standards are met

- Maintaining and cleaning glueline equipment to ensure optimal performance

2. Describe the different types of adhesives used in glueline applications.

Glueline Workers commonly work with a variety of adhesives, including:

Hot Melt Adhesives

- Thermoplastic materials that are applied in molten form and solidify upon cooling

- Advantages: High bond strength, fast setting time

Water-Based Adhesives

- Composed of water, resins, and other additives

- Advantages: Environmentally friendly, lower cost

Solvent-Based Adhesives

- Contain organic solvents that evaporate during bonding

- Advantages: Strong adhesion, versatility

3. What techniques do you use to ensure that glue is applied evenly and consistently?

To achieve even and consistent glue application, Glueline Workers employ techniques such as:

- Calibrating and adjusting glueline machines to precise settings

- Using specialized nozzles or applicators to control glue flow

- Monitoring glue viscosity and temperature to maintain optimal consistency

4. How do you troubleshoot common problems that may arise during glueline operations?

In the event of glueline issues, I follow a systematic troubleshooting process:

- Identifying potential causes of the problem, such as equipment malfunction, improper glue application, or environmental factors

- Inspecting equipment for any mechanical defects or blockages

- Adjusting machine settings, replacing worn parts, or cleaning clogged nozzles as necessary

5. What safety precautions do you take when working with adhesives and glueline equipment?

To ensure workplace safety, I strictly adhere to safety protocols:

- Wearing appropriate personal protective equipment, including gloves, safety glasses, and respirators when handling hazardous chemicals

- Following proper ventilation guidelines to minimize exposure to fumes or vapors

- Maintaining a clean and organized work area to prevent accidents

6. How do you maintain and calibrate glueline machinery to ensure optimal performance?

Regular maintenance and calibration are crucial for equipment efficiency:

- Performing routine inspections and cleaning of all machine components

- Calibrating pressure, temperature, and flow rate settings according to manufacturer specifications

- Replacing worn or damaged parts promptly to prevent breakdowns

7. Describe your experience with different glueline application techniques.

Throughout my career, I have gained proficiency in various glueline application techniques, including:

- Bead application: Applying glue in a continuous line

- Spray application: Using specialized equipment to evenly distribute glue over large surfaces

- Roller application: Employing rollers to transfer glue onto surfaces with precise thickness control

8. How do you handle situations where multiple glue types or formulations are required for a single project?

In such cases, I meticulously plan the application process:

- Identifying the specific bonding requirements and selecting the most suitable glue types

- Establishing clear transition points between different glues to prevent mixing or contamination

- Ensuring proper curing times and conditions for each glue type

9. What quality control measures do you implement to ensure the integrity of glued products?

To guarantee product quality, I adhere to rigorous quality control measures:

- Performing visual inspections to identify any defects in glue application

- Conducting adhesion tests to verify the strength and durability of glued joints

- Maintaining detailed records of all quality control procedures and results

10. How do you stay up-to-date with advancements in glueline technology and industry best practices?

I actively seek opportunities for professional development:

- Attending industry conferences and workshops

- Reading technical literature and journals

- Consulting with experts and vendors to learn about new technologies and techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glueline Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glueline Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Glueline Worker is responsible for the application of glue to wood products, ensuring proper bonding and alignment of materials in the production process.

1. Gluing and Assembly

Apply glue to wood surfaces using brushes, rollers, or sprayers.

- Ensure proper glue coverage and thickness to achieve strong bonds.

- Align and assemble wood components according to specifications.

2. Equipment Operation and Maintenance

Operate and maintain gluing machines and equipment, including spreaders and clamps.

- Monitor equipment performance and adjust settings to ensure optimal glue application.

- Clean and maintain equipment to prevent glue build-up and ensure efficient operation.

3. Inspection and Quality Control

Inspect glued joints and assemblies for proper alignment, strength, and appearance.

- Identify and correct any defects or imperfections in the gluing process.

- Adhere to quality standards and specifications to ensure product integrity.

4. Safety and Compliance

Maintain a safe work environment by following established safety protocols.

- Wear appropriate personal protective equipment, such as gloves and safety glasses.

- Adhere to hazardous materials handling procedures and environmental regulations.

Interview Tips

To ace an interview for a Glueline Worker position, it is crucial to prepare thoroughly and demonstrate your understanding of the role’s responsibilities and requirements.

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends.

- Visit the company’s website and social media profiles to gain insights into their culture and values.

- Stay updated on industry news and advancements to demonstrate your knowledge and interest.

2. Highlight Relevant Skills and Experience

Emphasize your experience in gluing and assembly, equipment operation, and quality control.

- Provide specific examples of projects or tasks you have successfully completed that demonstrate your skills.

- Quantify your accomplishments whenever possible to provide tangible evidence of your contributions.

3. Show Enthusiasm and Attention to Detail

Convey your passion for woodworking and your commitment to producing high-quality products.

- Discuss your attention to detail and your ability to identify and correct potential defects.

- Express your willingness to learn new techniques and contribute to the team’s success.

4. Practice Common Interview Questions

Prepare answers to common interview questions, such as:

- “Tell me about your experience in gluing and assembly.”

- “How do you ensure the quality of your work?”

- “What are your strengths and weaknesses as a Glueline Worker?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glueline Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.