Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gold Miner, Blasting position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

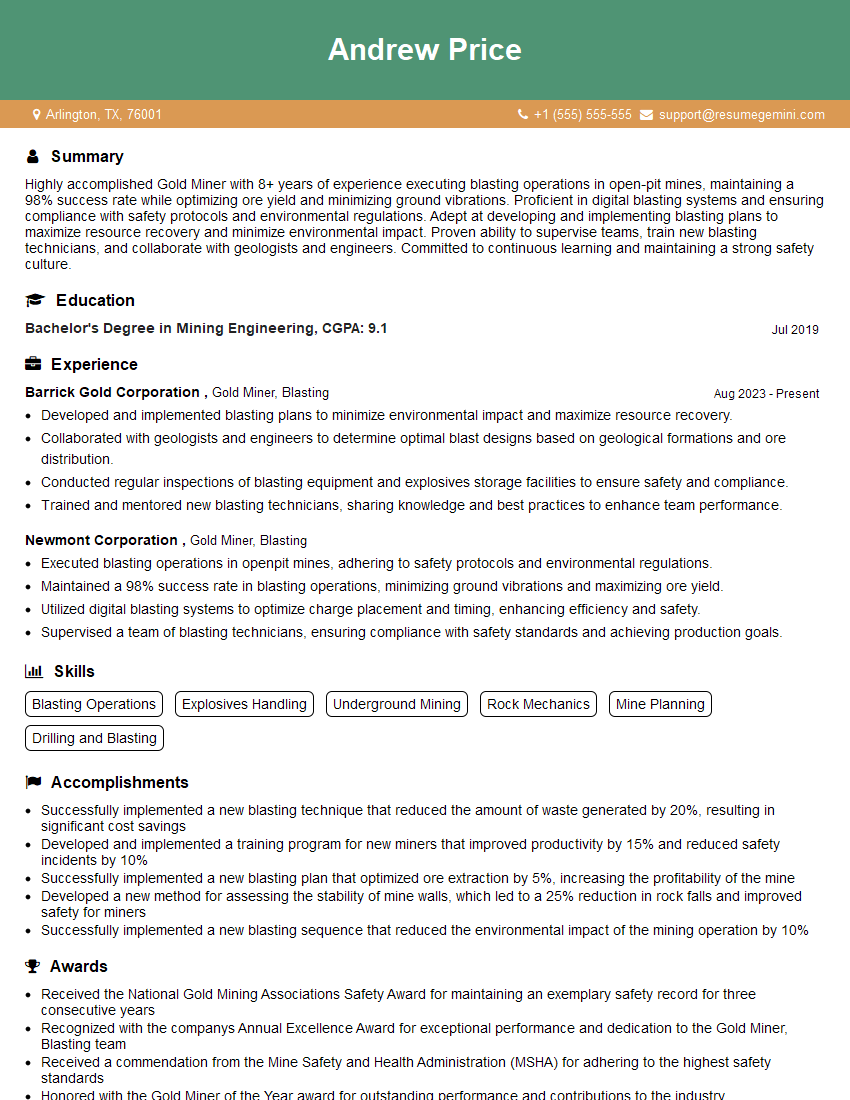

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gold Miner, Blasting

1. What are the different types of explosives used in gold mining, blasting?

There are several types of explosives used in gold mining, blasting, each with its own characteristics and applications. The most common types include:

- ANFO (Ammonium Nitrate Fuel Oil): A bulk explosive consisting of ammonium nitrate and fuel oil, used for large-scale blasting operations.

- Dynamite: A high-explosive consisting of nitroglycerin, used for smaller-scale blasting operations.

- Slurry explosives: Water-based explosives that are pumped into boreholes, offering flexibility and precision in blasting.

- Emulsion explosives: Gel-like explosives that are less sensitive to shock and heat, providing enhanced safety during handling.

- Detonating cords: Flexible explosives used to initiate larger explosions or to connect multiple charges.

2. What are the safety protocols you follow when handling and storing explosives?

Personal Protective Equipment

- Wear appropriate personal protective equipment (PPE) such as hard hats, safety glasses, gloves, and earplugs.

- Use non-sparking tools and avoid static electricity.

Storage and Handling

- Store explosives in a secure, well-ventilated magazine away from sources of heat and ignition.

- Keep explosives in original containers and follow manufacturer’s instructions for storage and handling.

- Inspect explosives regularly for any damage or deterioration.

Transportation

- Transport explosives in authorized vehicles with proper placards and safety measures in place.

- Follow prescribed routes and avoid populated areas.

3. How do you determine the appropriate blast design for a specific mining site?

- Geotechnical assessment: Analyze the rock properties, geological formations, and structural features of the site.

- Blast pattern design: Determine the hole spacing, burden, and depth based on the desired fragmentation and throw distance.

- Explosive selection: Choose the appropriate explosive type and charge size based on the rock properties and blast design.

- Delay sequencing: Plan the timing and sequence of blast detonations to optimize fragmentation and minimize ground vibration.

- Environmental considerations: Assess and mitigate potential environmental impacts such as noise, vibration, and dust.

4. What are the common challenges encountered in gold mining, blasting, and how do you overcome them?

- Ground vibration: Use proper blast design, delay sequencing, and vibration monitoring to minimize excessive ground vibrations.

- Flyrock: Control flyrock by using proper blasting techniques, mats, or barriers to trap debris.

- Blasting fumes: Implement proper ventilation and use low-emission explosives to reduce exposure to harmful fumes.

- Unstable ground conditions: Conduct thorough site assessments and use appropriate blasting techniques to minimize the risk of ground instability.

- Environmental concerns: Follow environmental regulations and implement measures to mitigate noise, vibration, and dust impacts.

5. How do you ensure the quality of your blasting operations?

- Pre-blast inspections: Conduct thorough inspections of the blast site and equipment to ensure safety and proper setup.

- Accurate hole drilling: Use precise drilling methods and equipment to ensure proper hole spacing and depth.

- Proper explosive loading: Follow specified loading procedures and use appropriate tools to avoid over or under-loading.

- Effective detonation: Use reliable detonation systems and timing devices to ensure accurate timing and consistent results.

- Post-blast evaluation: Inspect the blast site to assess fragmentation, throw distance, and ground vibration levels to identify areas for improvement.

6. What are the latest technologies or advancements in gold mining, blasting techniques?

- Electronic detonators: Provide precise timing and improved safety features.

- Digital blasting systems: Enable remote monitoring, data recording, and advanced blast design capabilities.

- 3D modeling and simulation software: Assist in optimizing blast designs and predicting potential impacts.

- GPS-guided drilling: Enhances hole accuracy and efficiency.

- Environmentally friendly explosives: Reduce harmful emissions and environmental impacts.

7. How do you stay updated with the latest industry best practices and regulations in gold mining, blasting?

- Attend industry conferences and workshops.

- Read technical journals and research papers.

- Participate in professional organizations and networks.

- Seek training and certifications from reputable institutions.

- Consult with experts and regulatory agencies to ensure compliance.

8. What are the key safety considerations when working with explosives in a gold mining environment?

- Employee training and competency: Ensure all personnel involved in blasting are properly trained and certified.

- Site security: Restrict access to blasting areas and implement security measures to prevent unauthorized entry.

- Proper storage and handling: Adhere to safe storage practices and follow manufacturer’s guidelines for handling and transportation.

- Emergency preparedness: Develop and implement emergency response plans in case of accidents or incidents.

- Communication and coordination: Establish clear lines of communication and ensure coordination between all team members.

9. How do you navigate and overcome geological challenges in gold mining, blasting operations?

- Geological assessment: Conduct thorough geological surveys to identify rock types, structures, and potential hazards.

- Adapting blast designs: Modify blast designs to accommodate variations in rock properties, such as hardness, fracturing, and water content.

- Specialized techniques: Employ specialized techniques such as pre-splitting or cushion blasting to minimize damage to sensitive formations.

- Environmental monitoring: Implement monitoring programs to assess the impact of blasting on the surrounding environment.

- Collaboration and expert consultation: Seek advice from geologists, engineers, and other experts to optimize blasting strategies.

10. Can you describe a specific example of a successful or challenging gold mining, blasting project you worked on?

- Describe the project scope and objectives.

- Explain your role and responsibilities.

- Discuss the challenges encountered and how you overcame them.

- Highlight the successful outcomes and lessons learned.

- Quantify results if possible (e.g., improved efficiency, reduced costs).

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gold Miner, Blasting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gold Miner, Blasting‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gold Miners, Blasting are responsible for using explosives to extract gold from underground mines. They work in dangerous conditions, so they must be well-trained and experienced. Their key responsibilities include:

1. Preparing the blast site

This involves clearing away any loose rock or debris, and marking the location of the blast holes.

- Ensuring that the blast site is safe for blasting

- Marking the location of the blast holes

2. Loading the blast holes

This involves filling the blast holes with explosives and detonators. The amount of explosives used will depend on the size of the rock formation being blasted.

- Selecting the correct type of explosives

- Calculating the amount of explosives needed

3. Detonating the explosives

This is done using a blasting machine. The blasting machine sends a electrical current to the detonators, which causes the explosives to detonate.

- Ensuring that the blasting machine is in good working order

- Detonating the explosives at the correct time

4. Mucking out the blast site

This involves removing the broken rock and debris from the blast site. This is done using a variety of equipment, such as shovels, bulldozers, and excavators.

- Ensuring that the blast site is safe for mucking

- Operating the equipment safely

Interview Tips

When preparing for an interview for a Gold Miner, Blasting position, there are a few things you can do to improve your chances of success.

1. Research the company and the position

This will help you to understand the company’s culture and values, as well as the specific requirements of the position. You can find this information on the company’s website, in trade publications, or by talking to people who work for the company or are familiar with similar position.

- Learn about the company’s history, products, and services

- Read the job description carefully and identify the key qualifications

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Use the STAR method to answer interview questions

- Prepare specific examples of your skills and experience

3. Be prepared to talk about your safety experience

Safety is a top priority in the mining industry, so you will need to be able to demonstrate your commitment to safety during the interview. Be prepared to talk about your safety training and experience, and how you would ensure the safety of yourself and your coworkers on the job.

- Highlight your training and experience in blasting safety

- Explain how you would implement safety procedures on the job

4. Be prepared to answer questions about your technical skills

You will also need to be able to demonstrate your technical skills during the interview. Be prepared to talk about your experience with explosives, blasting machines, and other equipment. You should also be able to explain the different types of blasting techniques and how you would choose the right technique for a particular job.

- Review the different types of explosives and blasting techniques

- Explain how you would calculate the amount of explosives needed for a particular job

Next Step:

Now that you’re armed with the knowledge of Gold Miner, Blasting interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Gold Miner, Blasting positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini