Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Gold Tooler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Gold Tooler so you can tailor your answers to impress potential employers.

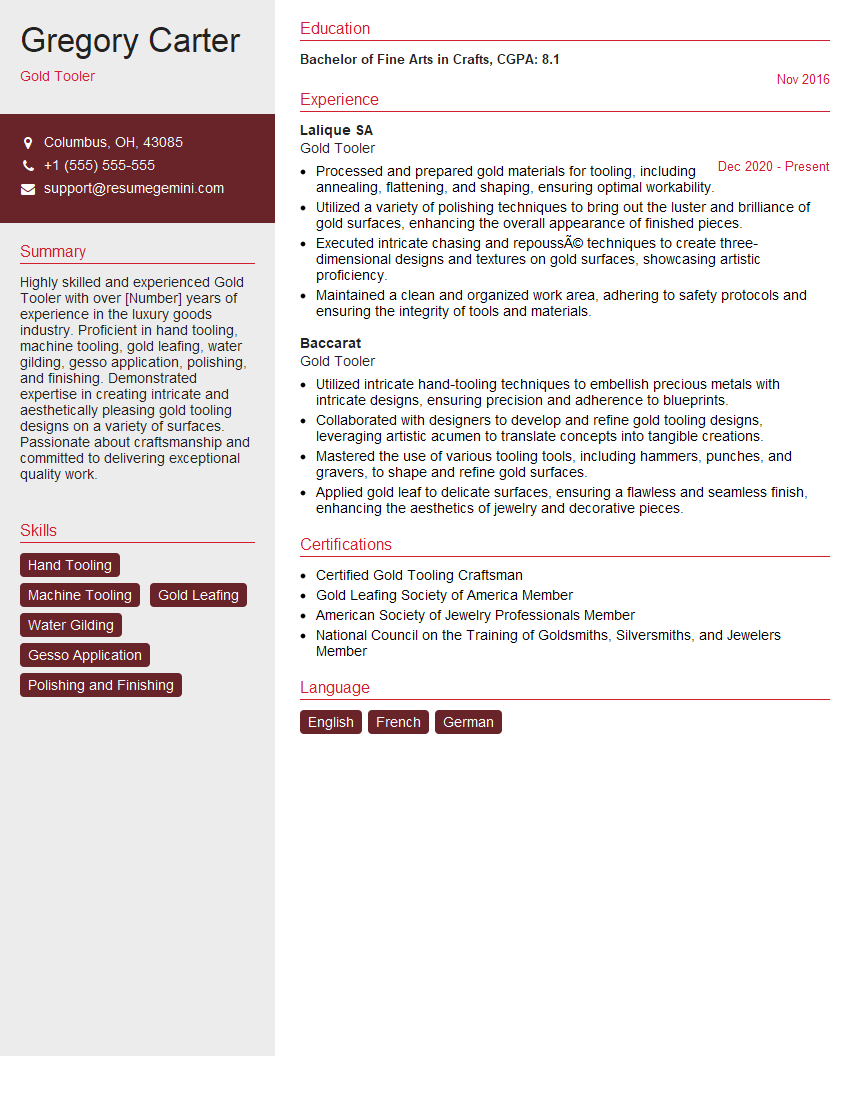

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gold Tooler

1. What is the difference between a flat turn and a raised turn?

Both flat turns and raised turns are used to shape metal, but they have different purposes and techniques:

- Flat turn: As the name suggests, a flat turn is used to create a flat surface on the metal. This is achieved by using a flat hammer or a planishing hammer to strike the metal in a straight line.

- Raised turn: A raised turn, on the other hand, is used to create a raised surface on the metal. This is achieved by using a raising hammer or a doming block to strike the metal in a circular motion.

2. What are the different types of hammers used in gold tooling?

There are many different types of hammers used in gold tooling, each with its own specific purpose and application:

Planishing hammers:

- Planishing hammers are used to create a flat surface on the metal. They are typically made of steel and have a flat face.

- Planishing hammers come in a variety of sizes and weights, depending on the thickness and hardness of the metal being worked.

Raising hammers:

- Raising hammers are used to create raised surfaces on the metal. They are typically made of steel and have a rounded face.

- Raising hammers come in a variety of sizes and weights, depending on the size and shape of the raised surface being created.

Doming blocks:

- Doming blocks are used to create curved surfaces on the metal. They are typically made of steel or wood and have a concave surface.

- Doming blocks come in a variety of sizes and shapes, depending on the size and shape of the curved surface being created.

3. What is annealing and why is it important in gold tooling?

Annealing is a process of heating and cooling metal to make it softer and more malleable. This is important in gold tooling because it allows the metal to be shaped and worked without cracking or breaking.

Annealing is typically done by heating the metal to a specific temperature and then allowing it to cool slowly. The temperature and cooling rate will vary depending on the type of metal being annealed.

4. What are the different types of finishes that can be applied to gold tooling?

There are many different types of finishes that can be applied to gold tooling, depending on the desired look and feel. Some of the most common finishes include:

- Polished finish: A polished finish is created by sanding and buffing the metal to a high shine.

- Brushed finish: A brushed finish is created by brushing the metal with a wire brush to create a matte surface.

- Antiqued finish: An antiqued finish is created by applying a chemical solution to the metal to create a darkened or aged look.

5. What are the different types of gold alloys used in gold tooling?

Gold alloys are used in gold tooling to create different colors and hardnesses of metal. Some of the most common gold alloys include:

- 24 karat gold: 24 karat gold is pure gold and is the softest and most malleable of all gold alloys.

- 18 karat gold: 18 karat gold is an alloy of 75% gold and 25% other metals, such as silver or copper. It is harder and more durable than 24 karat gold.

- 14 karat gold: 14 karat gold is an alloy of 58.3% gold and 41.7% other metals. It is harder and more durable than 18 karat gold.

6. What are the different types of tools used in gold tooling?

There are many different types of tools used in gold tooling, each with its own specific purpose and application. Some of the most common tools include:

- Hammers: Hammers are used to shape and form the metal.

- Anvils: Anvils are used to support the metal while it is being worked.

- Stakes: Stakes are used to hold the metal in place while it is being worked.

- Pliers: Pliers are used to bend and shape the metal.

- Files: Files are used to smooth and finish the metal.

7. What are the different techniques used in gold tooling?

There are many different techniques used in gold tooling, each with its own specific purpose and application. Some of the most common techniques include:

- Raising: Raising is a technique used to create raised surfaces on the metal.

- Planishing: Planishing is a technique used to create flat surfaces on the metal.

- Chasing: Chasing is a technique used to create designs on the metal by hammering it with a chasing tool.

- Repoussé: Repoussé is a technique used to create designs on the metal by pushing it from the back with a repoussé tool.

8. What are the different safety precautions that should be taken when working with gold tooling?

When working with gold tooling, it is important to take the following safety precautions:

- Wear safety glasses: Safety glasses will protect your eyes from flying metal chips and dust.

- Wear gloves: Gloves will protect your hands from cuts and abrasions.

- Use a dust mask: A dust mask will protect your lungs from inhaling metal dust.

- Work in a well-ventilated area: A well-ventilated area will help to prevent the build-up of metal dust.

- Be aware of your surroundings: Be aware of your surroundings and be careful not to trip or fall.

9. What are the different industries that use gold tooling?

Gold tooling is used in a variety of industries, including:

- Jewelry: Gold tooling is used to create jewelry such as rings, bracelets, and necklaces.

- Decorative arts: Gold tooling is used to create decorative objects such as picture frames, mirrors, and vases.

- Architecture: Gold tooling is used to create decorative elements for buildings, such as cornices, friezes, and pediments.

- Automotive: Gold tooling is used to create decorative elements for cars, such as grills, emblems, and dashboards.

10. What are the different career opportunities for gold toolers?

There are many different career opportunities for gold toolers, including:

- Goldsmith: Goldsmiths create jewelry and other decorative objects from gold.

- Metalworker: Metalworkers create objects from a variety of metals, including gold.

- Architect: Architects design buildings and other structures.

- Interior designer: Interior designers create the interior spaces of buildings.

- Teacher: Teachers teach gold tooling and other metalworking techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gold Tooler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gold Tooler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gold Toolers are responsible for creating intricate designs and patterns on gold and other precious metals.

1. Design and Pattern Creation

Their work involves:

- Hand-carving or using specialized tools to create designs on gold

- Creating custom designs or following existing patterns

2. Preparation of Gold

Before tooling, they may also be responsible for:

- Preparing gold by annealing (softening) it

- Cutting and shaping gold into desired forms

3. Tooling Techniques

They use various tooling techniques such as:

- Engraving (cutting lines and designs into the metal)

- Chasing (using tools to create raised designs)

- Repoussé (using tools to create designs from the back of the metal)

4. Attention to Detail

Gold Toolers require meticulous attention to detail and an artistic eye to create intricate designs.

- Ensuring precision and accuracy in their work

- Creating visually appealing and unique designs

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success.

1. Research the Position and Company

Familiarize yourself with the job description and research the company’s history, products/services, and industry.

- Demonstrate your interest in the specific role and why you’re a suitable candidate

- Show your understanding of the company’s culture and values

2. Practice Your Answers

Anticipate common interview questions and prepare concise, well-structured answers.

- Prepare examples that showcase your skills and experience

- Use the STAR method (Situation, Task, Action, Result) to provide clear and detailed responses

3. Showcase Your Portfolio

If applicable, bring a portfolio of your work or create an online portfolio that you can share with the interviewer.

- Visually demonstrate your technical abilities and artistic vision

- Highlight your ability to create original, high-quality designs

4. Emphasize Your Attention to Detail

Throughout the interview, emphasize your meticulous attention to detail and precision.

- Describe how you ensure accuracy and quality in your work

- Share examples of projects where you exhibited precision and attention to fine details

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Gold Tooler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Gold Tooler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.